Pressurized dissolved gas enhanced ozone pre-oxidation capability device and processing method thereof

A pressurized gas-dissolving and pre-oxidation technology, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of prolonged ozone residence time, low ozone utilization efficiency, and increased mass transfer efficiency, and achieve good practicability and social and economic benefits. Improved biochemical properties and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

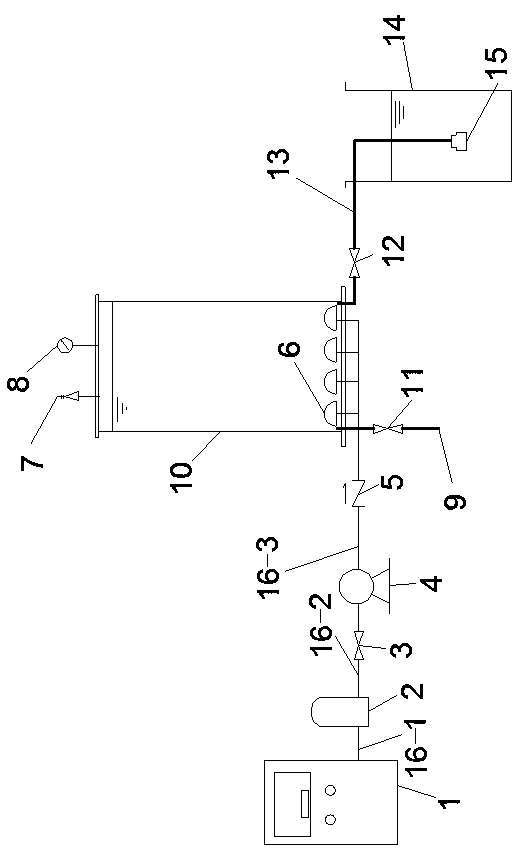

[0024] The technical solutions in the examples of the present invention will be described in detail below in conjunction with the accompanying drawings in the examples of the present invention.

[0025] A pressurized gas-dissolving device for enhancing ozone pre-oxidation capacity, comprising an ozone preparation system, a pressurization system, a pressure-dissolved air system, and a release system; the ozone preparation system includes an ozone generator 1, a gas storage tank 2 and a regulating valve 3; the pressurization The system includes a booster pump 4 and a check valve 5; the pressure dissolved air system includes a pressure tank 10 and a number of aeration heads 6, and a number of aeration heads 6 are arranged in the lower part of the pressure tank 10, and the upper part of the pressure tank 10 is provided with a safety valve 7 , Pressure gauge 8, the bottom is provided with water inlet pipe 9 and water inlet valve 11;

[0026] The ozone generator 1 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com