Low-loss cleaning process for leather

A low-damage, leather-based technology, applied in the field of cleaning, can solve the problems of washing machine damage, inability to remove dimethyl fumarate, surface damage, etc., and achieve the effects of inability to remove odors, excellent nursing effects, and non-volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

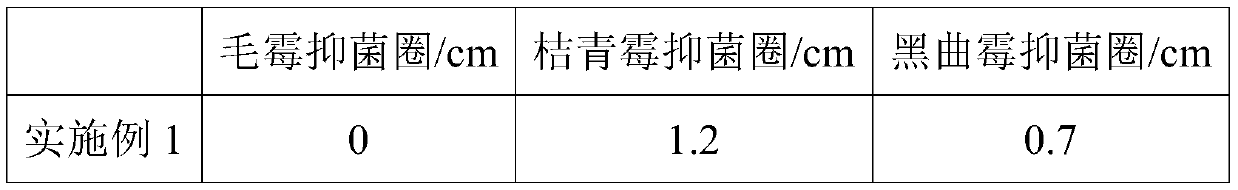

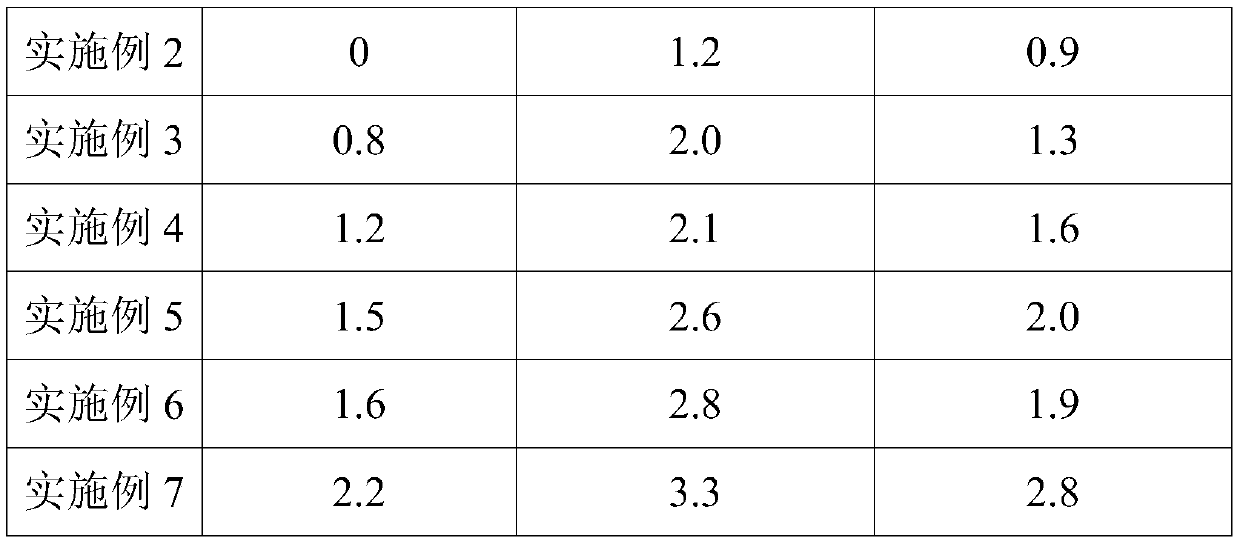

Examples

Embodiment 1

[0059] A low-damage cleaning process for leather, comprising the steps of:

[0060] (1) Spray cleaning solution on the leather surface, the amount of cleaning solution is 320mL / m 2 ;

[0061] The cleaning solution comprises 20 parts by weight of sophorose ester, 5 parts of active polysaccharide-collagen complex, 1 part of synthetic laponite, and 55 parts of water;

[0062] The preparation method of the active polysaccharide-collagen complex is as follows:

[0063] (1) 2 parts by weight of sugarcane polysaccharide and 1 part of collagen were dissolved in 100 parts of acetic acid, stirred at 300 rpm for 8 hours to obtain solution A;

[0064] (2) Mix solution A with an equal volume of solution B, stir at 300rpm for 15 minutes, adjust the pH value to 13 with solid sodium hydroxide, continue to stir at 300rpm for 36 hours, centrifuge at 10000rpm for 20 minutes, take the solid, and put it at 100Pa / 60℃ Vacuum dried to constant weight, namely;

[0065] The solution B is a mixture ...

Embodiment 2

[0080] A low-damage cleaning process for leather, comprising the steps of:

[0081] (1) Spray cleaning solution on the leather surface, the amount of cleaning solution is 320mL / m 2 ;

[0082] The cleaning solution comprises 20 parts by weight of sophorose ester, 5 parts of active polysaccharide-collagen complex, 1 part of synthetic laponite, and 55 parts of water;

[0083] The preparation method of the active polysaccharide-collagen complex is as follows:

[0084] (1) 2 parts by weight of sugarcane polysaccharide and 1 part of collagen were dissolved in 100 parts of acetic acid, stirred at 300 rpm for 8 hours to obtain solution A;

[0085] (2) Mix solution A with an equal volume of solution B, stir at 300rpm for 15 minutes, adjust the pH value to 13 with solid sodium hydroxide, continue to stir at 300rpm for 36 hours, centrifuge at 10000rpm for 20 minutes, take the solid, and put it at 100Pa / 60℃ Vacuum dried to constant weight, namely;

[0086] The solution B is a mixture ...

Embodiment 3

[0101] A low-damage cleaning process for leather, comprising the steps of:

[0102] (1) Spray cleaning solution on the leather surface, the amount of cleaning solution is 320mL / m 2 ;

[0103] The cleaning solution comprises 20 parts by weight of sophorose ester, 5 parts of active polysaccharide-collagen complex, 1 part of synthetic laponite, and 55 parts of water;

[0104] The preparation method of the active polysaccharide-collagen complex is as follows:

[0105] (1) 2 parts by weight of sugarcane polysaccharide and 1 part of collagen were dissolved in 100 parts of acetic acid, stirred at 300 rpm for 8 hours to obtain solution A;

[0106] (2) Mix solution A with an equal volume of solution B, stir at 300rpm for 15 minutes, adjust the pH value to 13 with solid sodium hydroxide, continue to stir at 300rpm for 36 hours, centrifuge at 10000rpm for 20 minutes, take the solid, and put it at 100Pa / 60℃ Vacuum dried to constant weight, namely;

[0107] The solution B is a mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com