An Intelligent Control System of Temperature and Humidity in Spinning Workshop

A technology of an intelligent control system and a central control system, applied in the directions of space heating and ventilation control input, control input involving environmental factors, and control input involving air characteristics, etc., can solve the problem of product performance degradation and unclear basis for equipment frequency adjustment. , can not be precisely controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

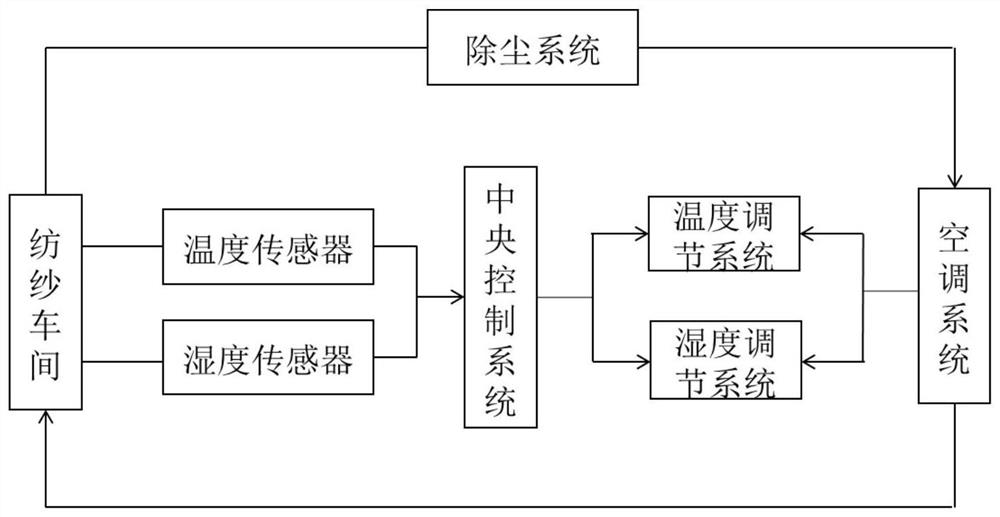

[0034] An intelligent temperature and humidity control system in a spinning workshop, such as figure 1 As shown, it includes a temperature and humidity sensor installed in the spinning workshop, an air-conditioning system installed in the air-conditioning room, and a central control system. The air-conditioning system and the dust removal system are connected through ventilation ducts to recycle the air in the spinning workshop; the central control system The system includes a coarse adjustment system and a fine adjustment system. The coarse adjustment system obtains the ambient temperature and humidity data in real time, presets the temperature and humidity control parameters in advance, and sends a coarse adjustment instruction signal to the air conditioning system. The fine adjustment system receives the monitoring data of the temperature and humidity sensor in real time. The real-time monitoring data of temperature and humidity sends a fine-tuning instruction signal to the ...

Embodiment 2

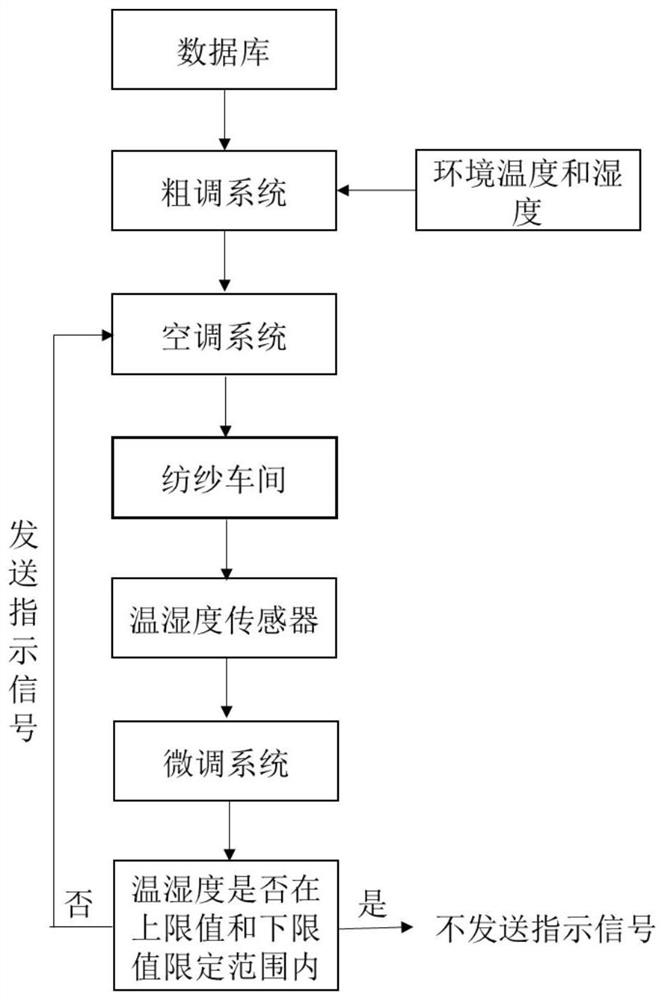

[0060] A temperature and humidity control method in an intelligent spinning workshop, such as figure 2 As shown, using the temperature and humidity control system described in Embodiment 1, the temperature and humidity control method includes the following steps:

[0061] S1. The starting time is the moment when all the spinning equipment in the spinning workshop is turned on, which is recorded as 0h. The coarse adjustment system obtains the local weather forecast information for the next 0-24h through the wireless network, and extracts t from it. 1 , t 2 ,...,t 24 The ambient temperature and humidity data at any time, denoted as T 1 ,T 2 ,...,T 24 and M 1 ,M 2 ,...,M 24 ;

[0062] S2. Coarsely tune the system call database with t 1 Time temperature and humidity T 1 and M 1 The theoretical temperature and humidity control parameters under the corresponding temperature and humidity conditions, and use this as the preset temperature and humidity control parameters, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com