An automatic production line for punching and polishing melamine tableware and its process

A technology for automatic production lines and tableware, which is applied in the direction of grinding feed motion, grinding workpiece support, grinding machine, etc. Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

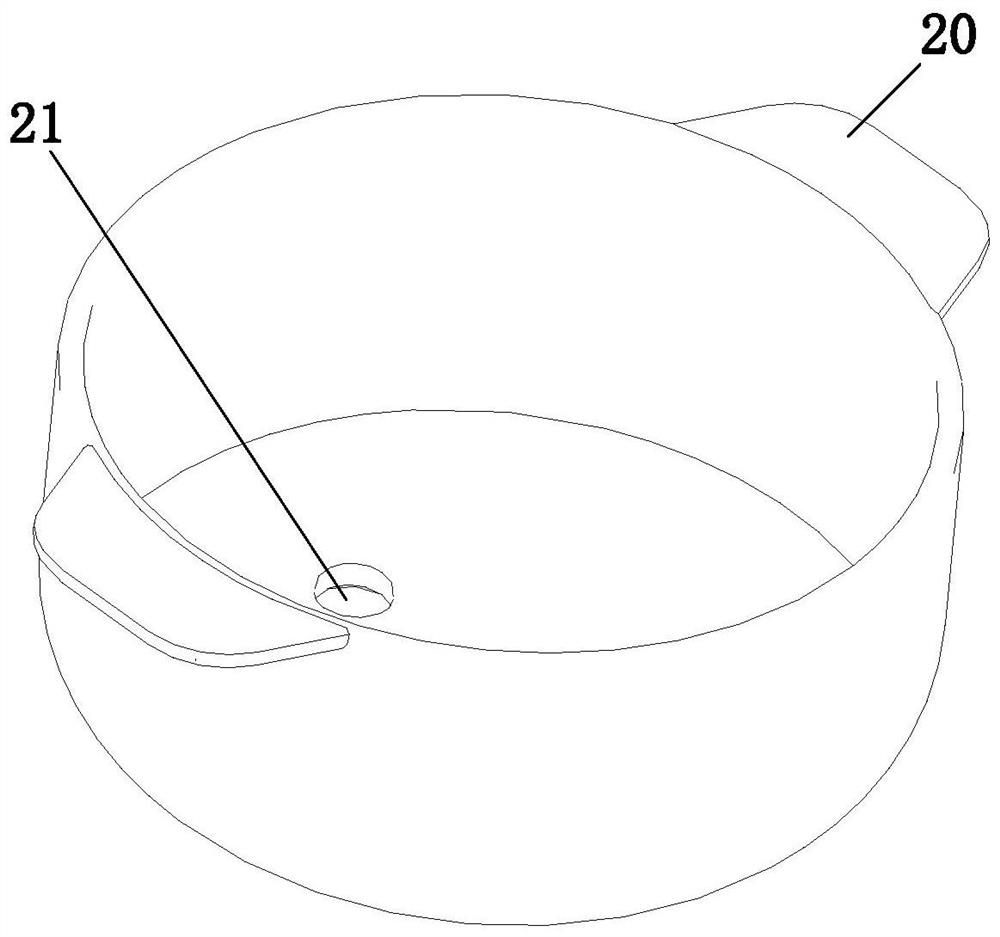

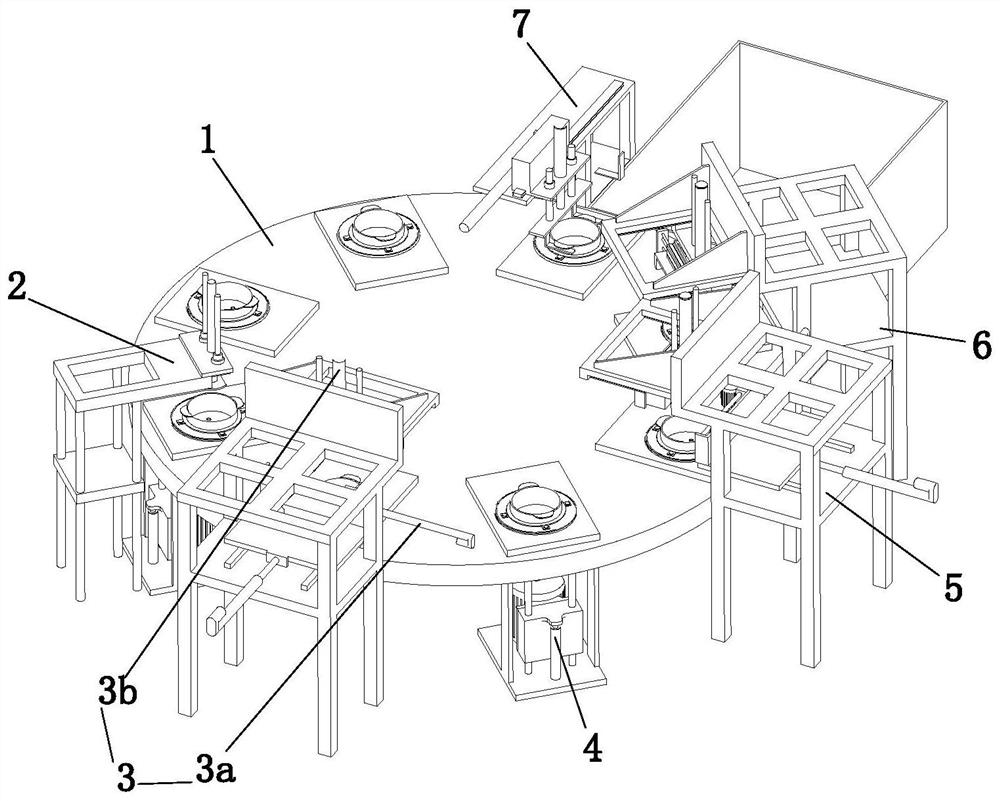

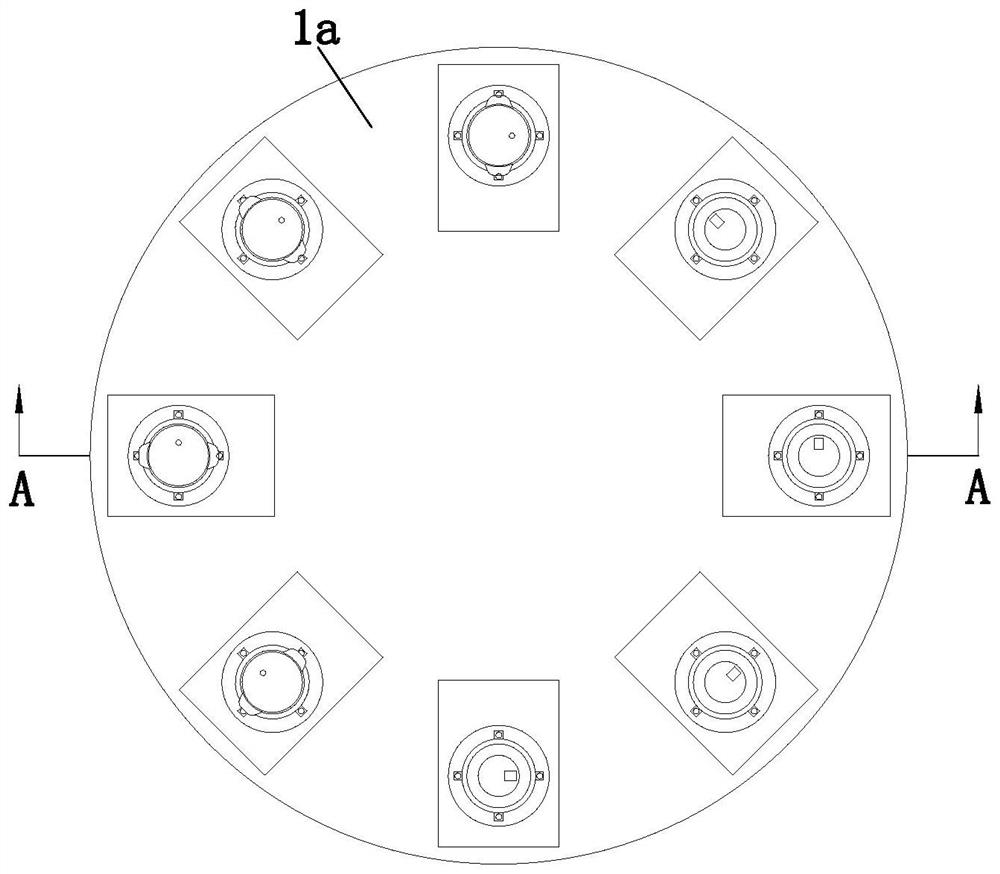

[0059] Combine below Figure 1 to Figure 13As shown, the embodiment of the present invention provides an automatic production line for punching and polishing melamine tableware, including a transport mechanism 1, a positioning mechanism 2, a first polishing mechanism 3, a rotating mechanism 4, a second polishing mechanism 5, and a punching mechanism 6 and a blanking mechanism 7, the transport mechanism 1 includes a transport assembly 1a and several restricting assemblies 1b, and several restricting assemblies 1b are circumferentially arranged on the transporting assembly 1a, the positioning mechanism 2, the first grinding mechanism 3, the rotating mechanism 4. The second grinding mechanism 5, the punching mechanism 6 and the unloading mechanism 7 are circumferentially distributed on the side of the transport mechanism 1 in turn. The positioning mechanism 2 includes a rotating assembly 2a and a positioning assembly 2b, and the positioning assembly Just above the assembly 2a, th...

Embodiment 2

[0070] The present invention also provides a process for melamine tableware perforation and polishing automatic production line, and the process steps are:

[0071] S1: Mechanical adjustment; select the appropriate jig 1a3c according to the size of the processed melamine tableware, install the jig 1a3c on the station seat 1a3b, and adjust the distance between the two lifting plates 7g;

[0072] S2: Loading; manually place the processed melamine tableware in the jig 1a3c at the feeding position, and drive the transport turntable 1a2 to rotate through the operation of the transport motor 1a1, and the transport turntable 1a2 drives the melamine tableware in the jig 1a3c to rotate;

[0073] S3: Positioning; the positioning assembly 2b works, the lifting cylinder 2b1b works to push the lifting block 2b1c downward, and the lifting block 2b1c drives the positioning member 2b2 at its lower end to move downward until the positioning plate 2b2b is located at the upper end of the melamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com