Filtration and pressing equipment in a sesame oil processing procedure

A processing procedure and technology for sesame oil, which is applied in the field of filtering and pressing equipment in the processing procedure of sesame oil, can solve the problems of insufficient oil diversion and filtration, insufficient sesame pressing, low pressing efficiency, etc. High, smooth diversion, efficient filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

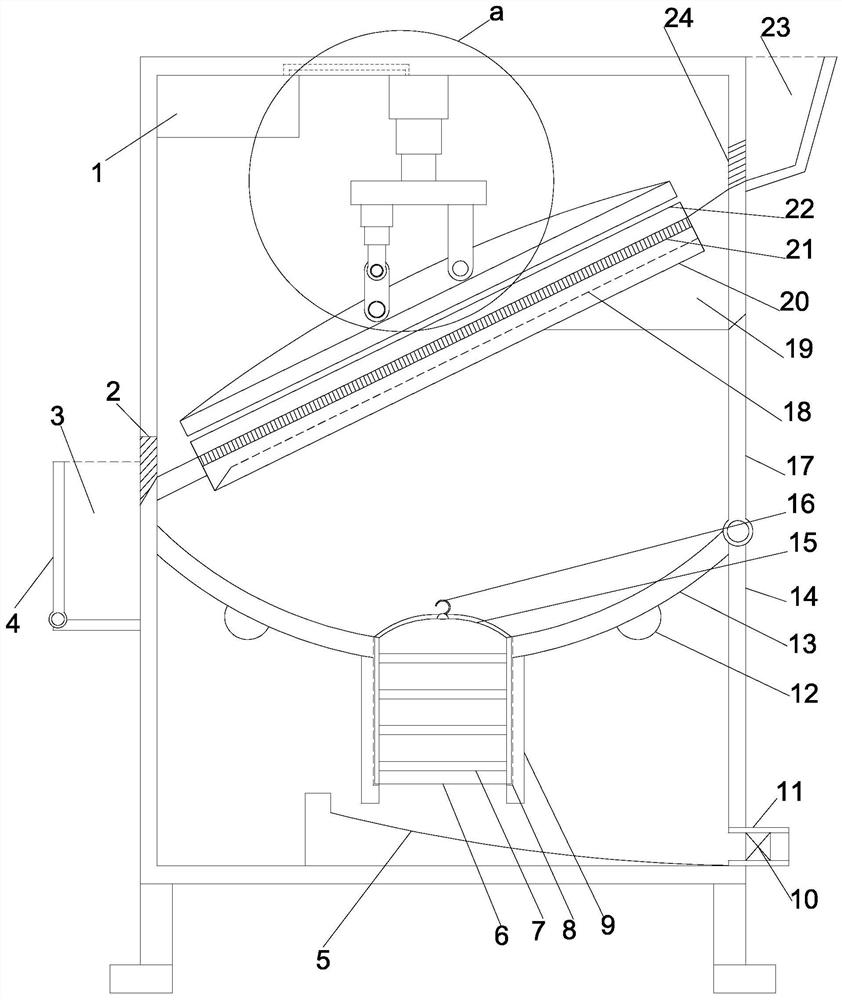

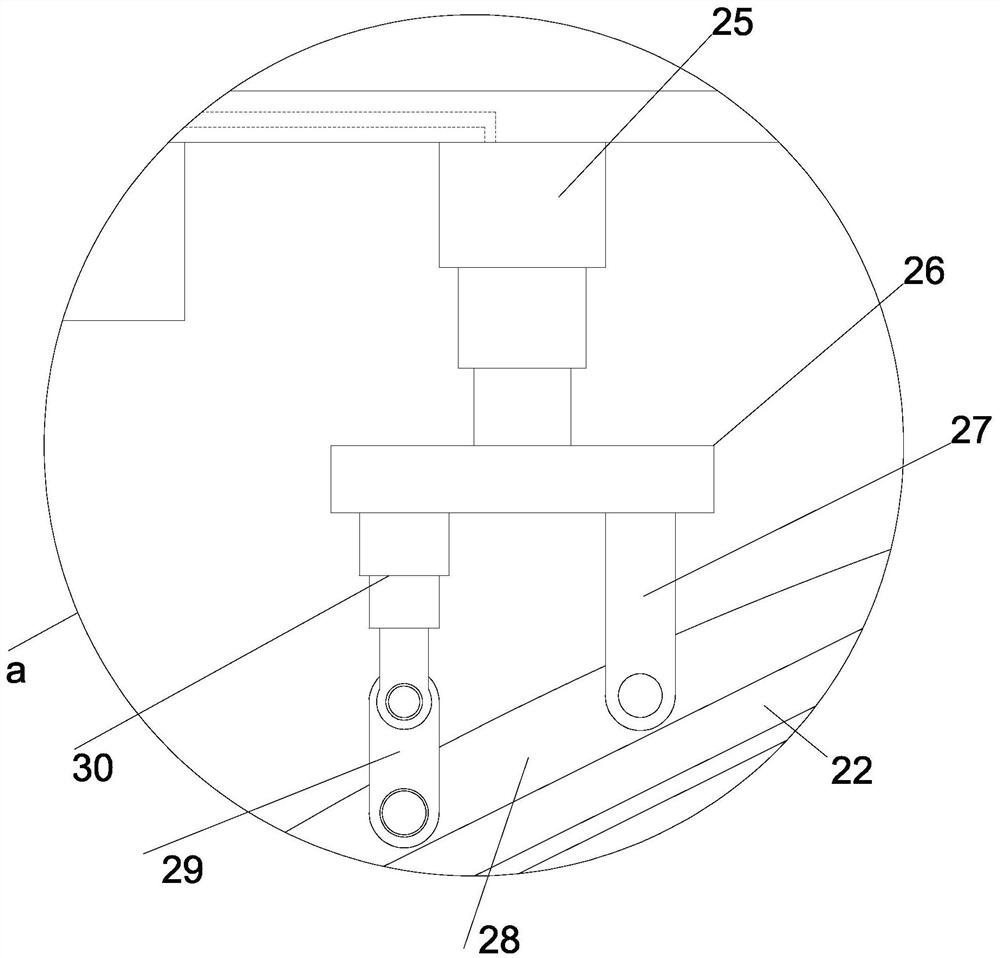

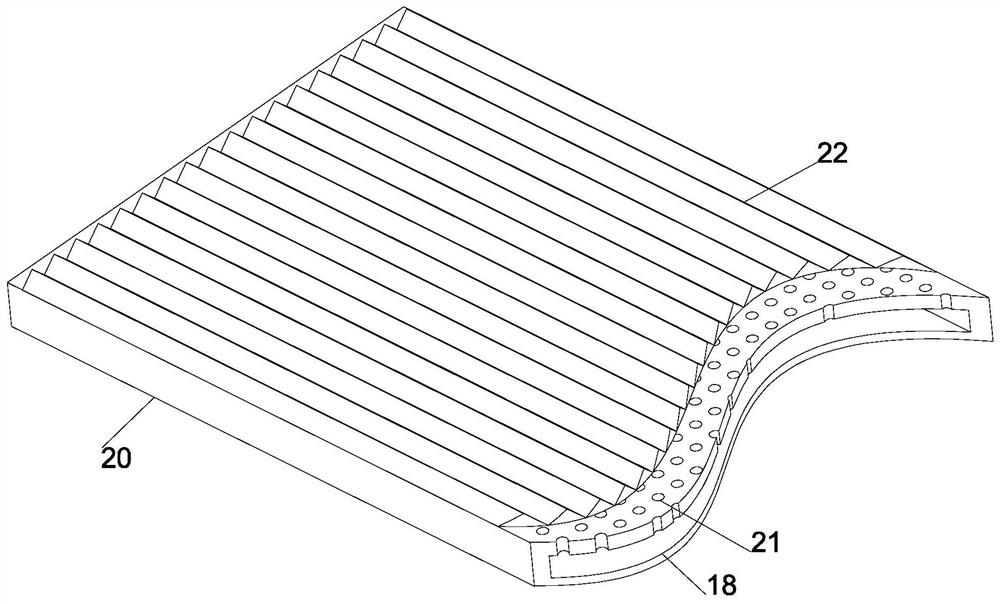

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of filtering and pressing equipment in the sesame oil processing procedure, comprises the support installation cylinder 14 that is vertically arranged, and the four corners of the lower end of support installation cylinder 14 are all provided with support installation columns, and the upper right corner of support installation cylinder 14 is provided with There is a feeding cylinder 23, and the supporting installation cylinder 14 corresponding to the lower end of the feeding cylinder 23 is provided with a feeding hole 24, and the lower right corner of the supporting installation cylinder 14 is provided with a discharge pipe 11, and the inside of the discharge pipe 11 is provided with a solenoid valve 10 , the middle position of the support installation cylinder 14 is horizontally provided with an arc surface guide cylinder 13, the support installation cylinder 14 at the right end of the arc surface guid...

Embodiment 2

[0024] On the basis of the first embodiment, through the operation of the vibrator 12, the curved surface guiding cylinder 13 and the filter flow installation cylinder 6 are vibrated synchronously to realize the accelerated filtration of the oil, and the filter flow installation cylinder 6 cooperates with the limit installation groove 8 to guide The installation enables the filter flow installation cylinder 6 to be quickly installed and replaced, so as to realize continuous operation and improve efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com