Preparation method of antioxidant masterbatch based on mbz

A technology of antioxidant and masterbatch, which is applied in the field of preparation of antioxidant masterbatch, can solve the problems of cable breakdown appearance, defects, poor long-term thermal aging resistance of cable materials, etc., to facilitate transportation and storage, The effect of reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

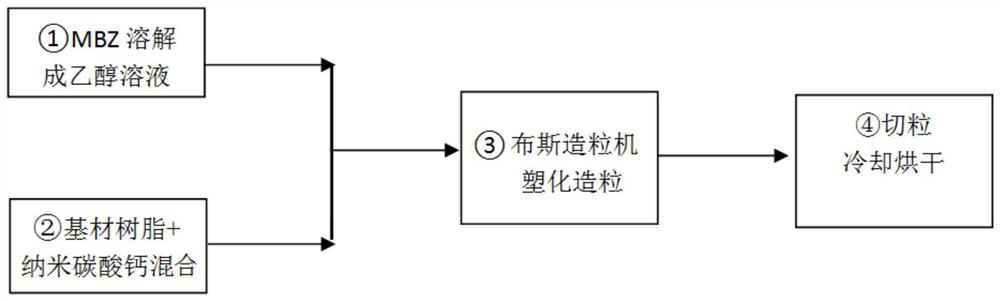

[0036] A preparation method of the antioxidant masterbatch based on MBZ of the present invention, by weight, the antioxidant masterbatch includes the following components in mass ratio: 30-40 parts of MBZ, 30-40 parts of industrial ethanol, base material 100 parts of resin, 20-30 parts of nanometer calcium carbonate. Antioxidant masterbatch is plasticized and granulated by Buss granulator, which specifically includes the following steps:

[0037] (1) MBZ (with a fineness of about 600 mesh) and industrial ethanol are dissolved in a 5L large round bottom flask according to the mass ratio of MBZ: ethanol = 1:1, and the dissolution process is heated while stirring on the constant temperature electric heating mantle, controlled Stir for 8-10 minutes at a temperature of 70-80°C until a uniform viscous solution is formed, and inject it into the 2# liquid feeding tank of the Booth granulator for use.

[0038] (2) Put substrate resin linear low density polyethylene LLDPE7042 (melt ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com