Electroplating device for gear machining

An electroplating device and gear technology, which is applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems such as the influence of gear use quality, and achieve the effect of good electroplating quality and convenient electroplating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

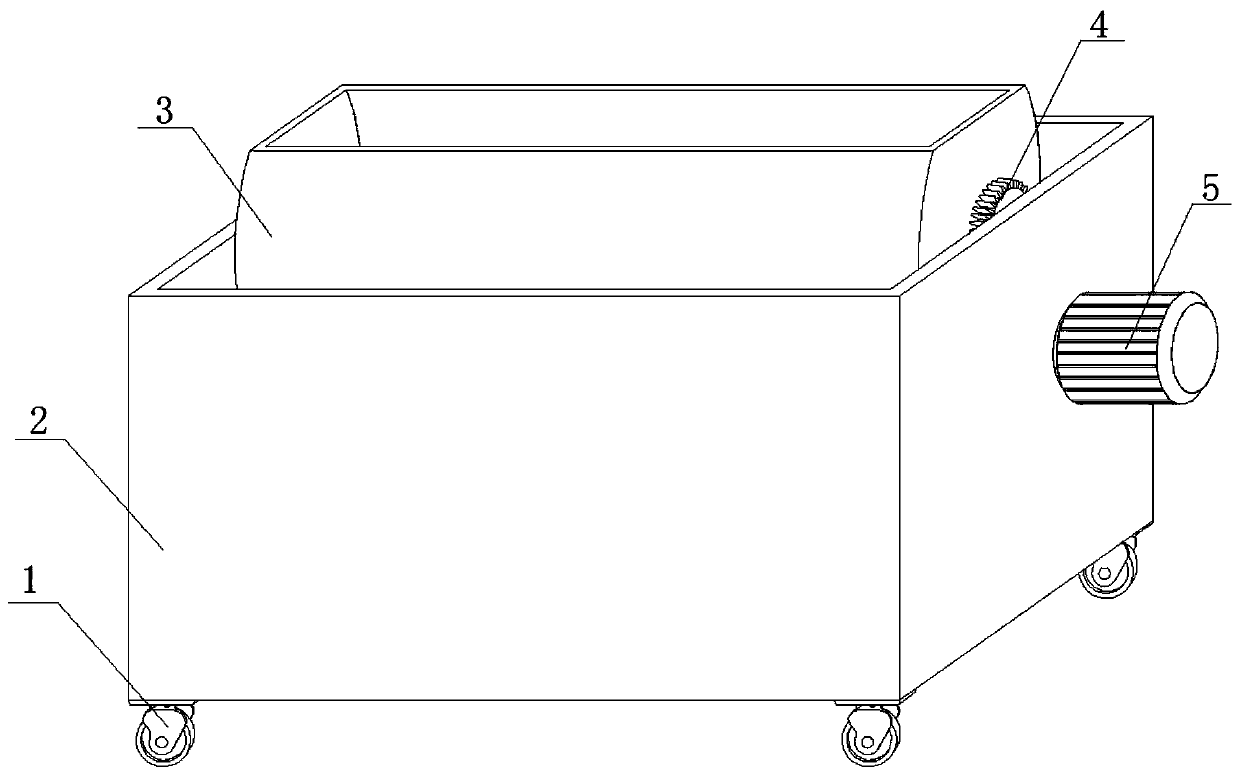

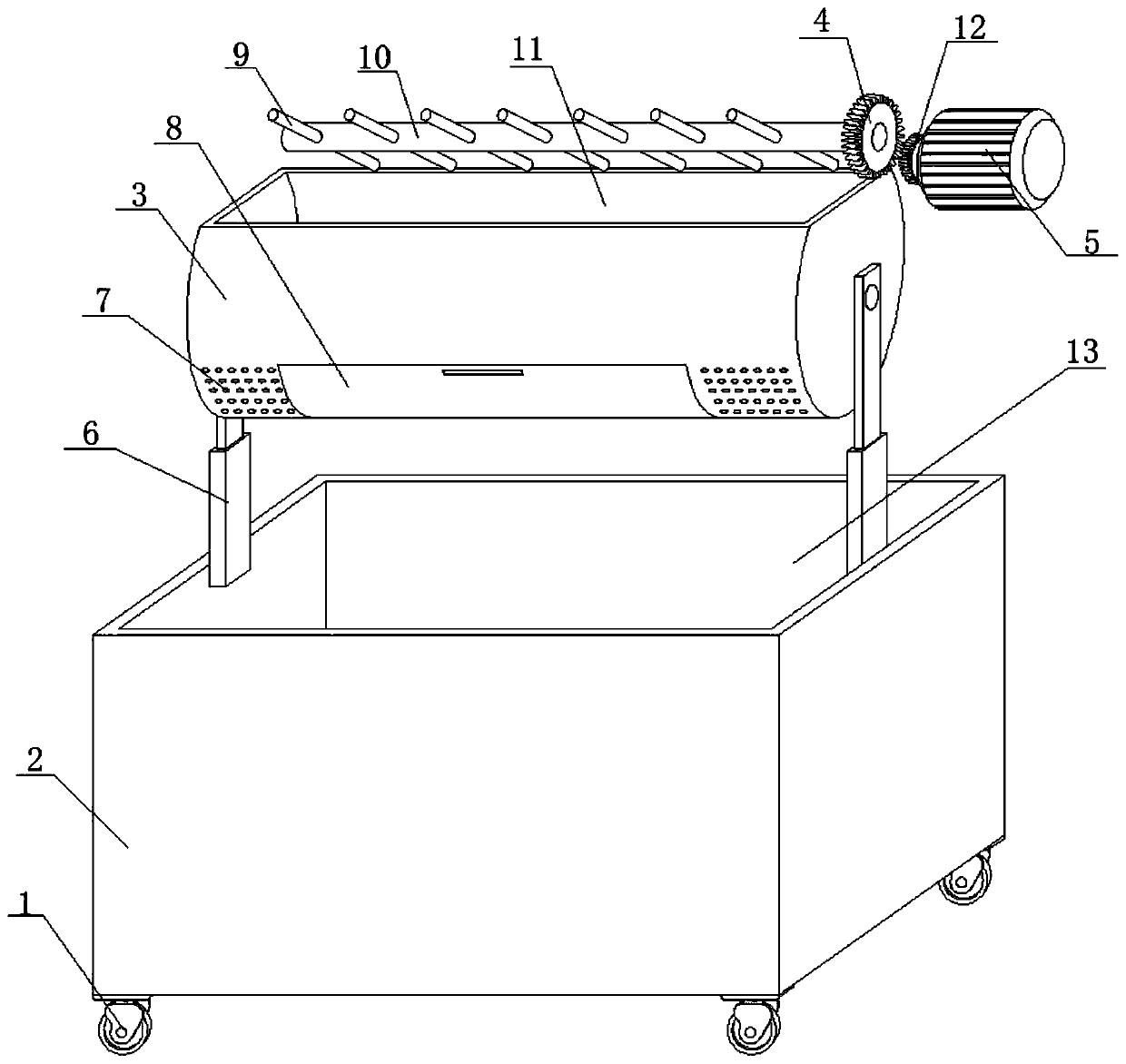

[0026] refer to Figure 1-2 , an electroplating device for gear processing, comprising an electroplating cabinet 2, an electroplating solution tank 13 is arranged inside the electroplating cabinet 2, and both ends of the bottom inner wall of the electroplating cabinet 2 are connected with vertically arranged pneumatic push rods 6 by bolts, two The same horizontal electroplating collection barrel 3 is installed between the adjacent two ends of the pneumatic push rod 6, the circumferential inner wall of the electroplating collection barrel 3 is set as an electroplating tank 11, and the inner walls of the two ends of the electroplating collection barrel 3 are uniform The same horizontally arranged rotating roller 10 is sleeved through the bearing, and the peripheral outer wall of the rotating roller 10 is equipped with a vertically arranged mixing rod 9 , and the circumferential bottom of the electroplating collecting barrel 3 is provided with an electroplating solution through ho...

Embodiment 2

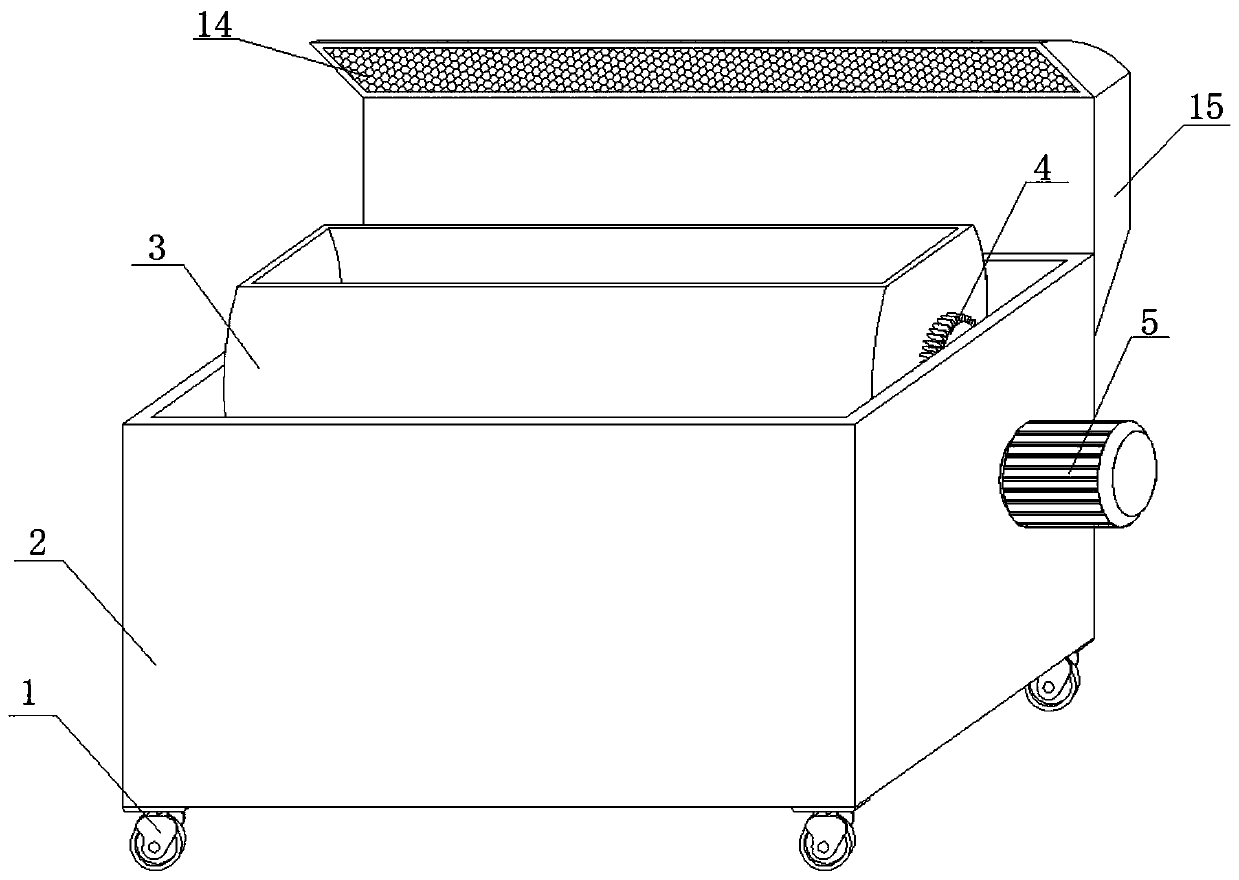

[0029] refer to Figure 1-3 , an electroplating device for gear processing, the top of one side of the electroplating machine case 2 is connected with a vertically arranged purification bellows 15 by bolts, and the inside of the purification bellows 15 is equipped with a purification fan, and the top of the purification bellows 15 is equipped with a wind bucket 14, And the wind bucket 14 is located on the top of the electroplating tank 11, and the exhaust gas generated by electroplating can be filtered through the internal purification device, and the harmful substances therein can be treated, so that the electroplating device is more environmentally friendly.

[0030] Working principle: When using the electroplating device for gear processing, the operator first moves the electroplating device to a suitable working position through the moving wheel 1 at the bottom, fixes the electroplating device stably and then connects it to the power supply, and the operator pours the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com