Bamboo charcoal fiber fabric for home textiles and preparation method thereof

A bamboo charcoal fiber and fabric technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of poor quality of bamboo charcoal fiber fabrics, achieve good antibacterial properties, good elasticity, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

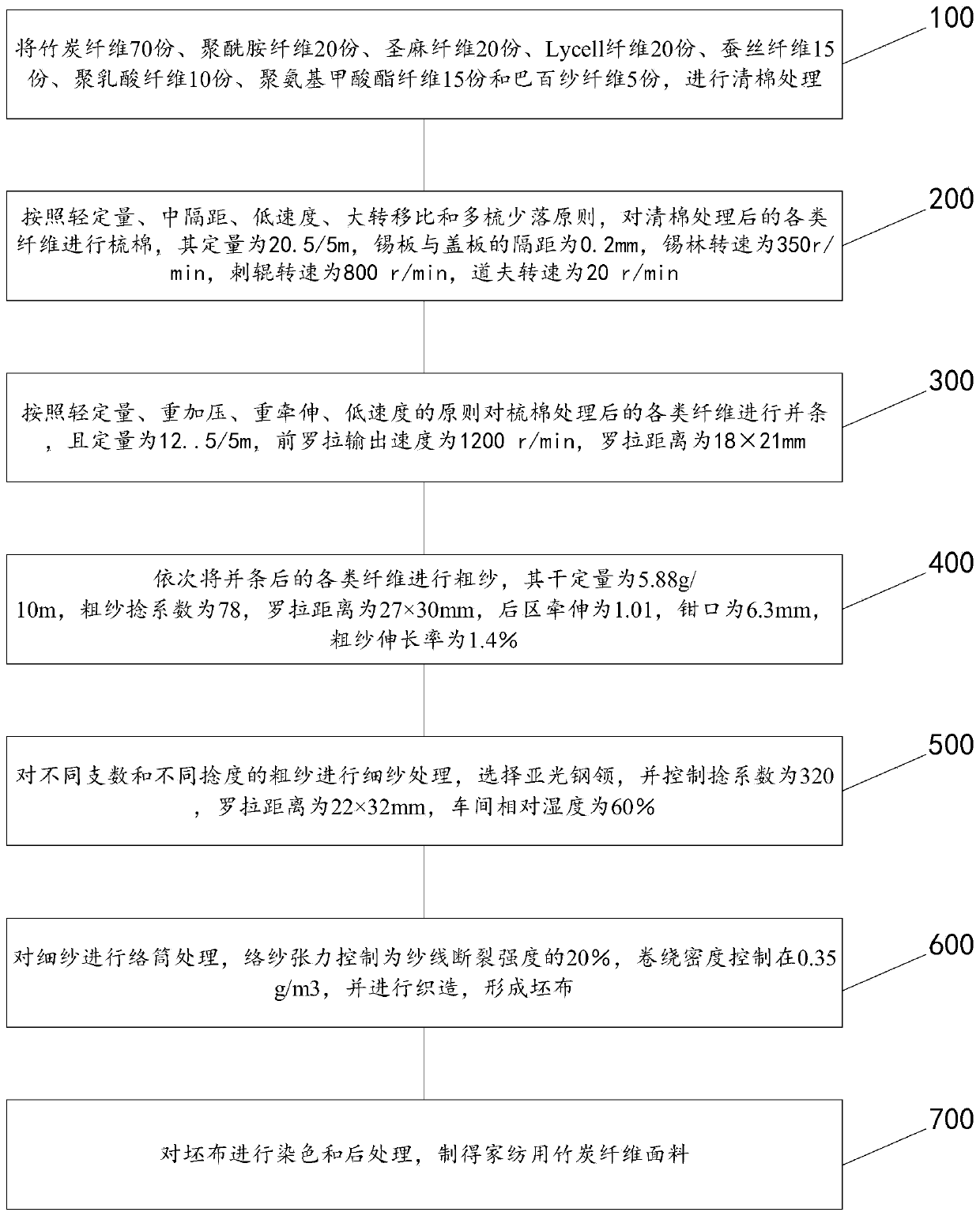

Embodiment 1

[0022] S100: Mix 70 parts of bamboo charcoal fiber, 20 parts of polyamide fiber, 20 parts of holy hemp fiber, 20 parts of Lycell fiber, 15 parts of silk fiber, 10 parts of polylactic acid fiber, 15 parts of polyurethane fiber and 5 parts of yarn fiber Cotton cleaning treatment;

[0023] Among them, the various fibers of the above-mentioned parts by mass are cleaned on the parallel disc plucking machine, single-axis flow cotton opener, multi-compartment blending machine, vibrating cotton box feeder, and single-hand lapping machine in sequence. After the cleaning process, the carding process is carried out. The bamboo charcoal fiber is made of moso bamboo, and the new calcination process and new technology of pure oxygen high temperature and nitrogen barrier delay are used to make the micropores inherent in bamboo charcoal more refined and honeycombed. Then it is made by melt spinning with polyester modified chips with honeycomb microporous structure trend. Bamboo charcoal fiber...

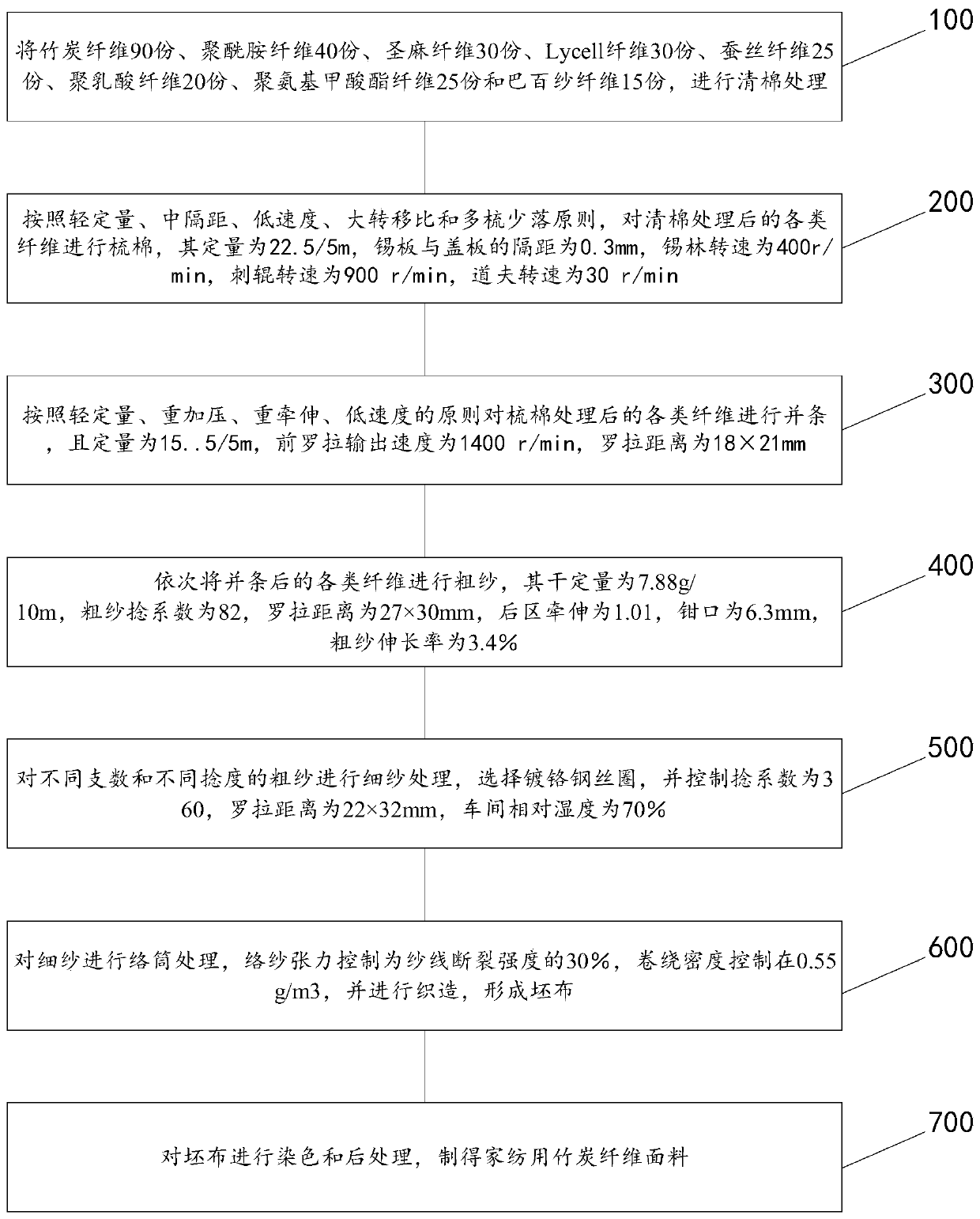

Embodiment 2

[0037] S100: 90 parts of bamboo charcoal fiber, 40 parts of polyamide fiber, 30 parts of holy hemp fiber, 30 parts of Lycell fiber, 25 parts of silk fiber, 20 parts of polylactic acid fiber, 25 parts of polyurethane fiber and 15 parts of voile fiber Cotton cleaning treatment;

[0038] Among them, the various fibers of the above-mentioned parts by mass are cleaned on the parallel disc plucking machine, single-axis flow cotton opener, multi-compartment blending machine, vibrating cotton box feeder, and single-hand lapping machine in sequence. After the cleaning process, the carding process is carried out. The bamboo charcoal fiber is made of moso bamboo, and the new calcination process and new technology of pure oxygen high temperature and nitrogen barrier delay are used to make the micropores inherent in bamboo charcoal more refined and honeycombed. Then it is made by melt spinning with polyester modified chips with honeycomb microporous structure trend. Bamboo charcoal fiber i...

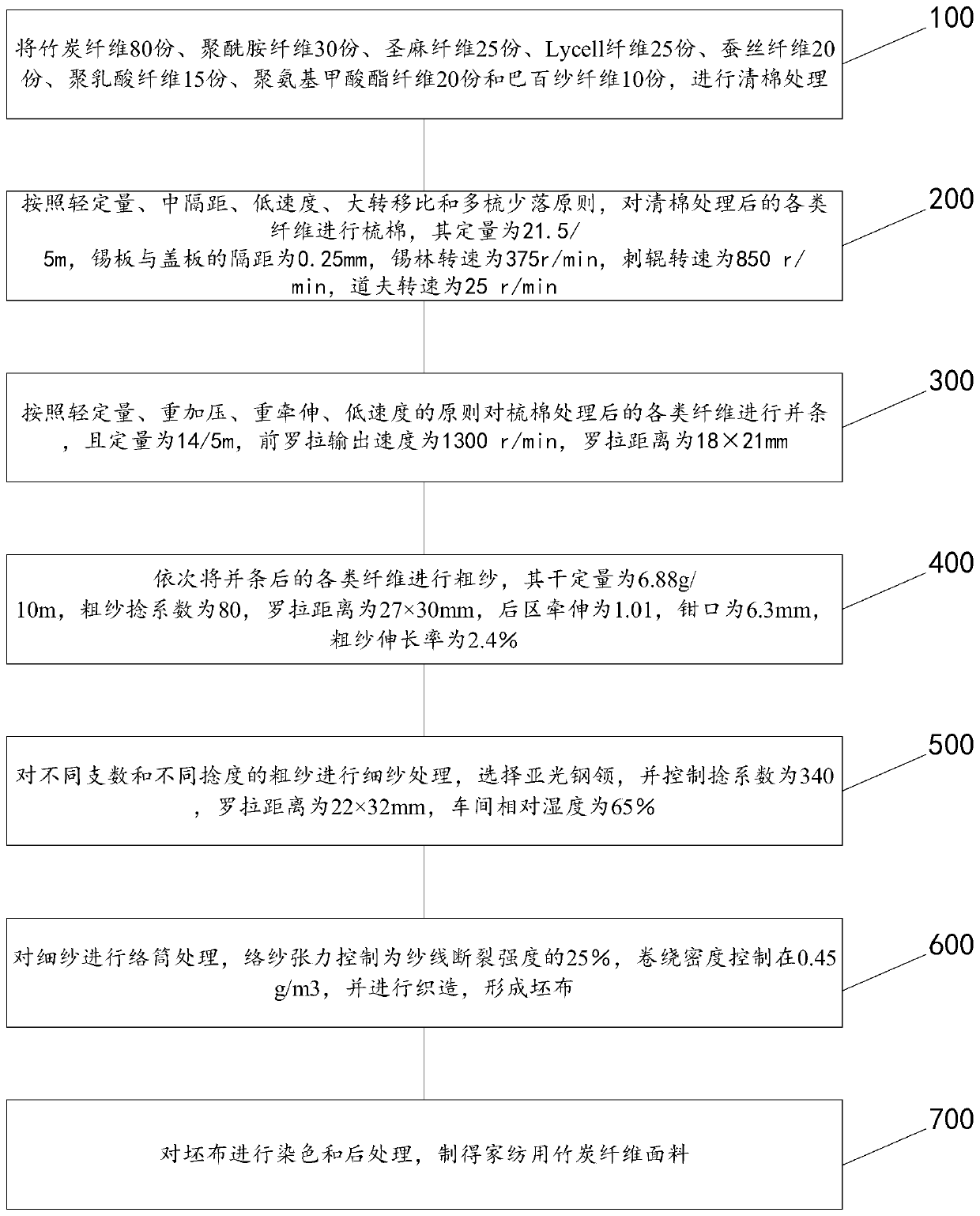

Embodiment 3

[0052] S100: Mix 80 parts of bamboo charcoal fiber, 30 parts of polyamide fiber, 25 parts of holy hemp fiber, 25 parts of Lycell fiber, 20 parts of silk fiber, 15 parts of polylactic acid fiber, 20 parts of polyurethane fiber and 10 parts of voile fiber Cotton cleaning treatment;

[0053]Among them, the various fibers of the above-mentioned parts by mass are cleaned on the parallel disc plucking machine, single-axis flow cotton opener, multi-compartment blending machine, vibrating cotton box feeder, and single-hand lapping machine in sequence. After the cleaning process, the carding process is carried out. The bamboo charcoal fiber is made of moso bamboo, and the new calcination process and new technology of pure oxygen high temperature and nitrogen barrier delay are used to make the micropores inherent in bamboo charcoal more refined and honeycombed. Then it is made by melt spinning with polyester modified chips with honeycomb microporous structure trend. Bamboo charcoal fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com