Drying system and drying method

A drying system and drying technology, applied in the direction of drying safety system, drying of granular materials, drying of solid materials, etc., can solve the problems of increasing moisture content and achieve the effect of inhibiting moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0038] In addition, in some drawings, some symbols existing in other drawings are omitted.

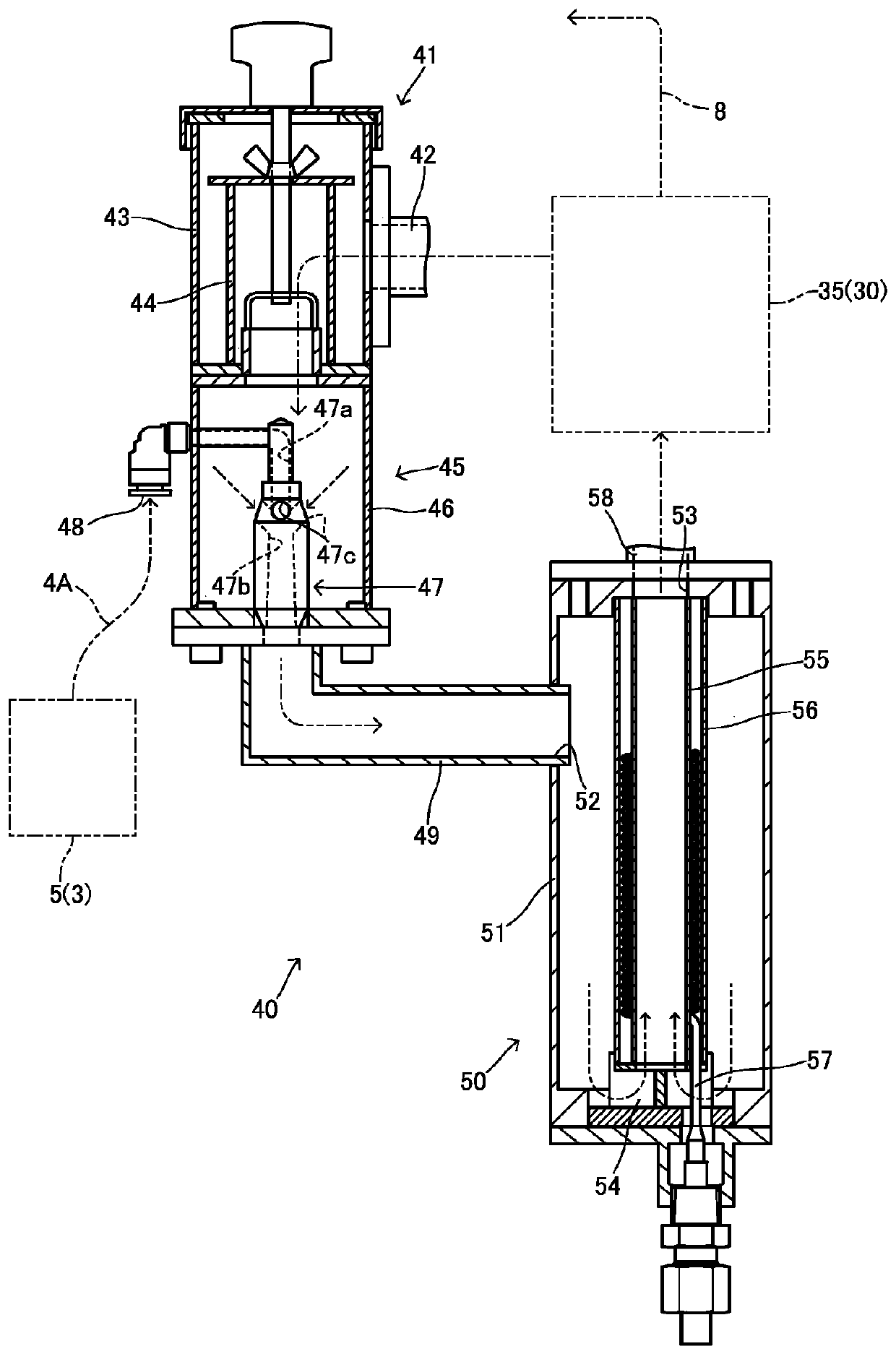

[0039] In addition, in figure 1 as well as figure 2 In , a part of the pipeline (pipe) which becomes the path through which the powdery material, gas, etc. pass is schematically shown by the dashed-two dotted line.

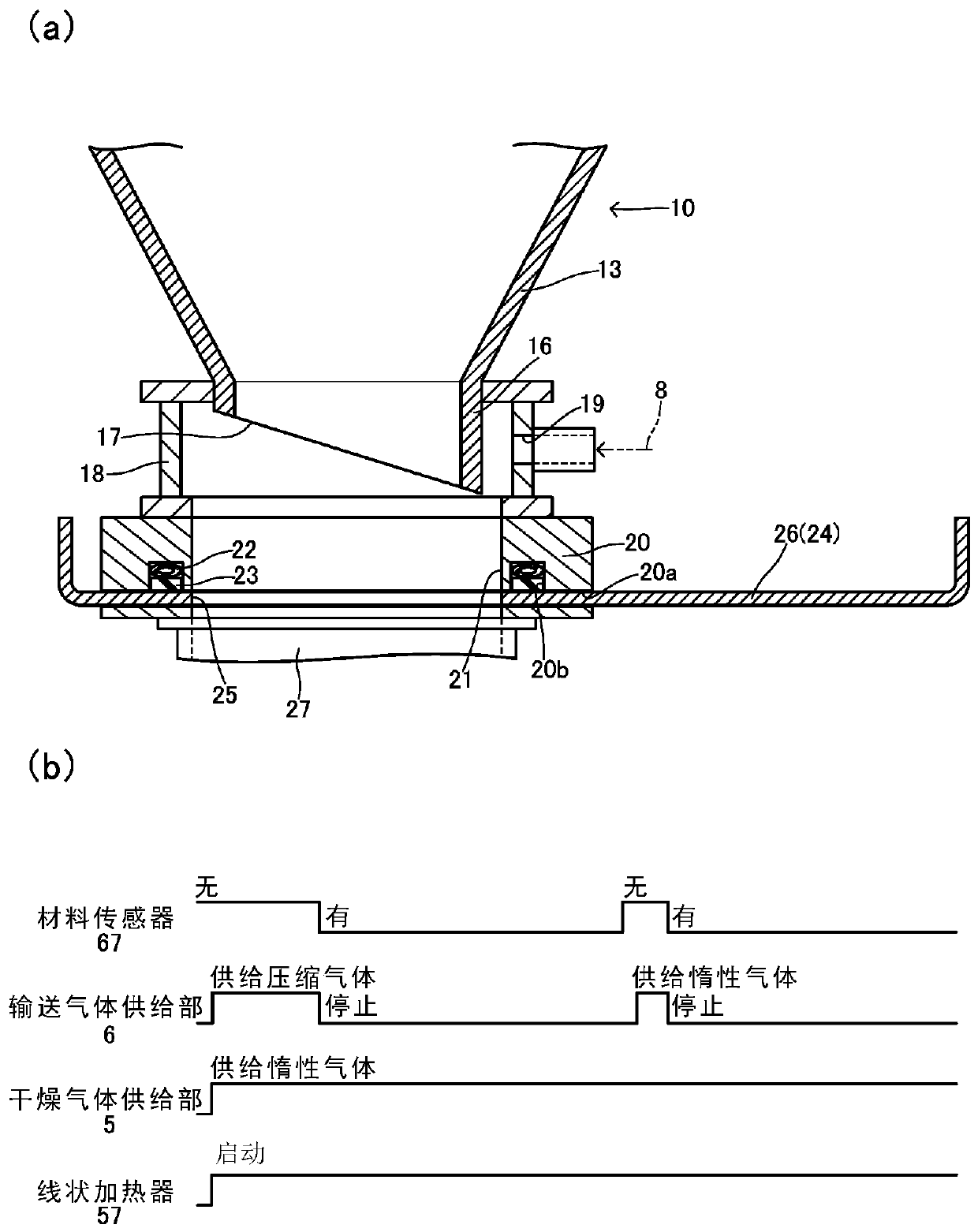

[0040] In addition, in image 3 The schematic timing chart of (b) schematically shows the detection or switching of each device, ON (turning on, starting) / OFF (breaking, turning off), and the like.

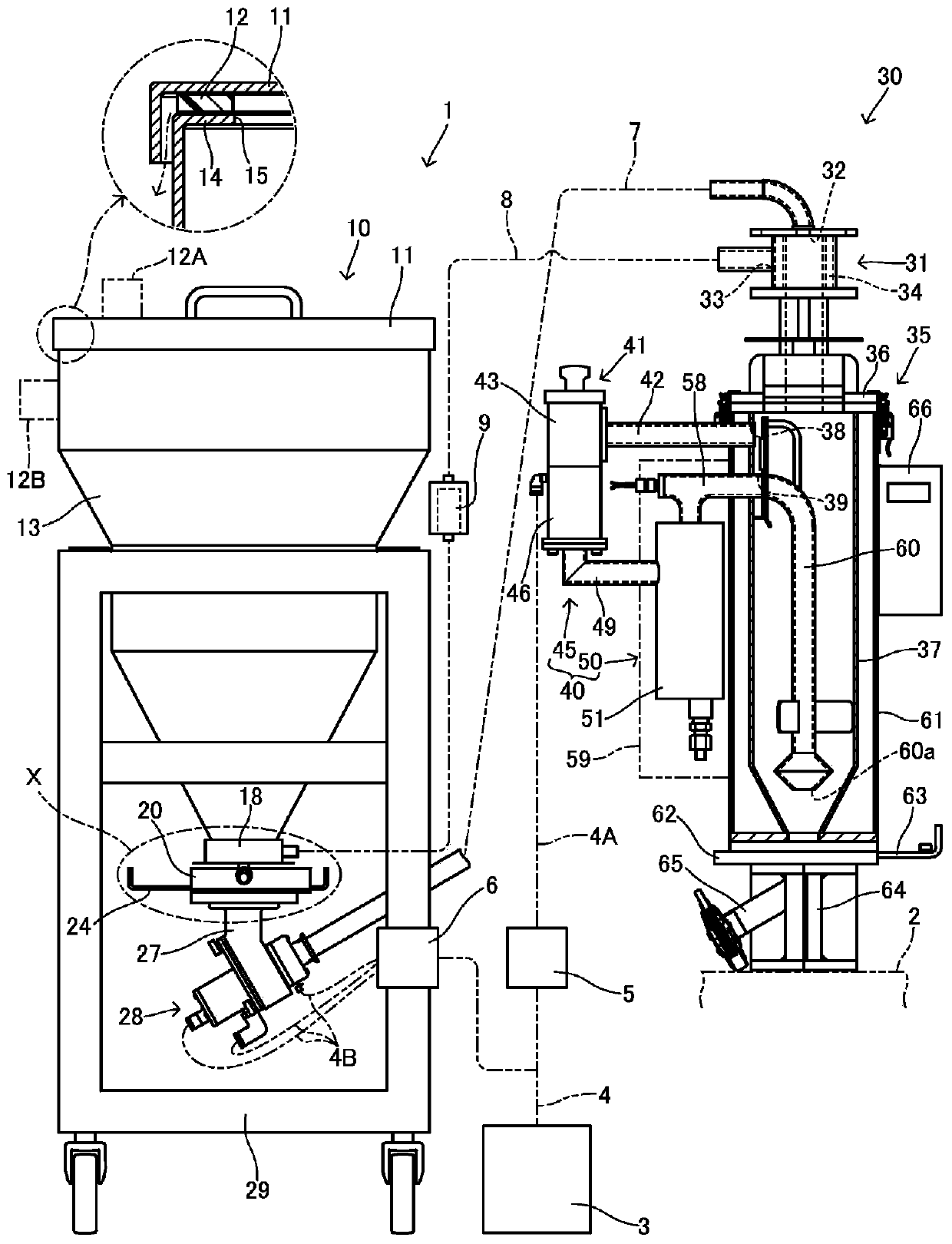

[0041] Figure 1 ~ Figure 3 It is a figure which schematically shows an example of the drying system which concerns on this embodiment, and an example of the drying method performed using this drying system.

[0042] Such as figure 1 As shown, the drying system 1 according to this embodiment includes: a storage tank 10 for storing powdery or granular materials; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com