Humidity sensor based on substrate integrated waveguide reentrant resonant cavity

A substrate-integrated waveguide and humidity sensor technology, applied in the field of sensors, can solve the problems of large size of microwave passive sensors, reduction of relative volume of resonant cavity, and low quality factor, so as to ensure high quality factor, improve sensing sensitivity, and broad The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better illustrate the design process and purpose, the present invention will be further described below in conjunction with the embodiments and the accompanying drawings:

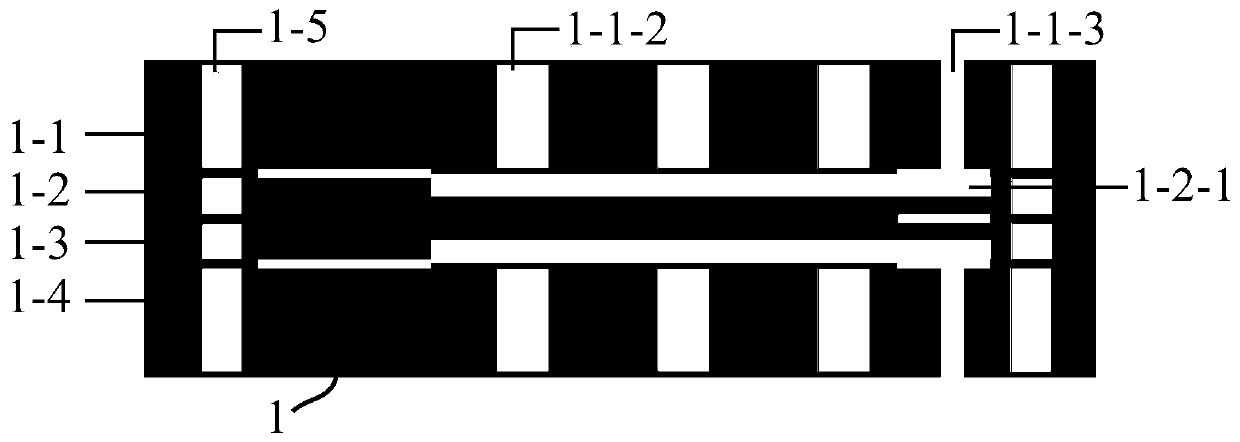

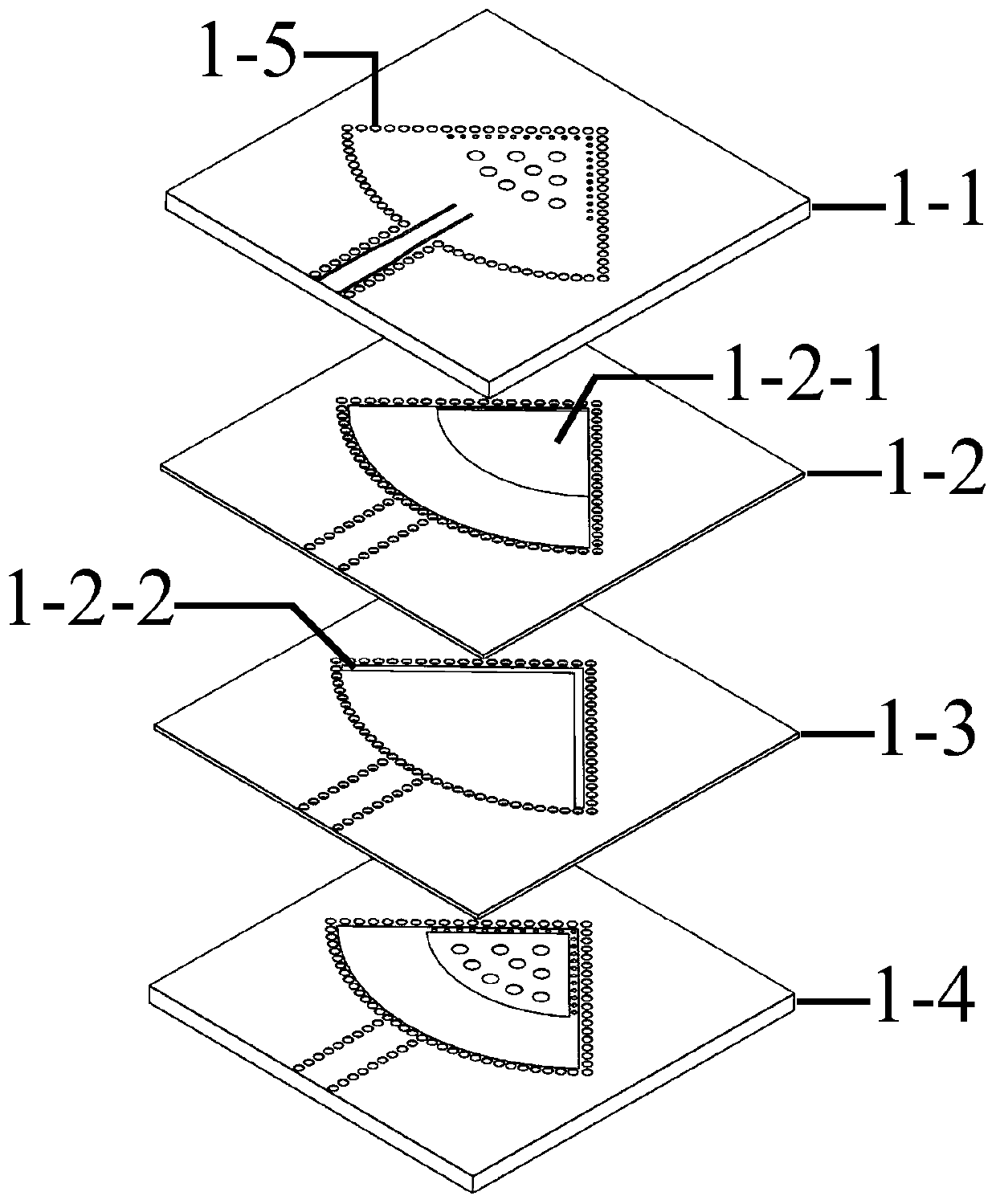

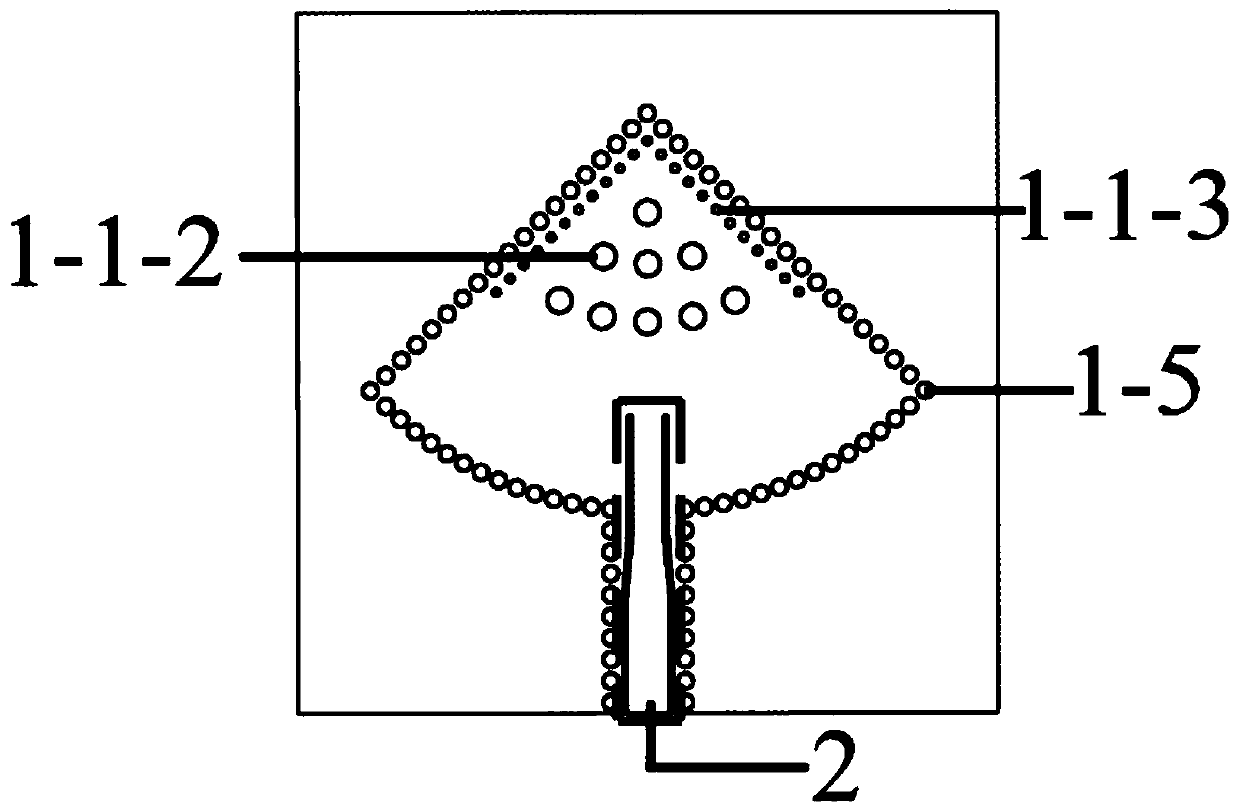

[0033] like Figure 1 to Figure 6(a) As shown in Fig. 6(b), the sensor based on the substrate integrated waveguide re-entrant re-entrant cavity proposed by the present invention comprises a substrate integrated waveguide re-entrant re-entrant re-entrant resonant cavity (1) and a section of coplanar waveguide feed with a characteristic impedance of 50Ω. Wire (2).

[0034] The resonant cavity (1) comprises a first dielectric substrate (1-1), a second dielectric substrate (1-2), a third dielectric substrate (1-3) and a fourth dielectric substrate (1-4), four The substrates are stacked vertically, and a resonant cavity cavity is formed in the middle, and the shape of the resonant cavity cavity is a quarter circle. The first dielectric substrate (1-1), the second dielectric substrate (1-2), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outside width | aaaaa | aaaaa |

| Inner width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com