Iodomethane test method and method for testing adsorption efficiency of activated carbon

A technology of activated carbon adsorption and testing methods, applied in separation methods, chemical instruments and methods, measuring devices, etc., can solve problems such as radioactive leakage, operators and environmental pollution, achieve reliable results, accurate test results, and solve the problem of radioactive methyl iodide leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

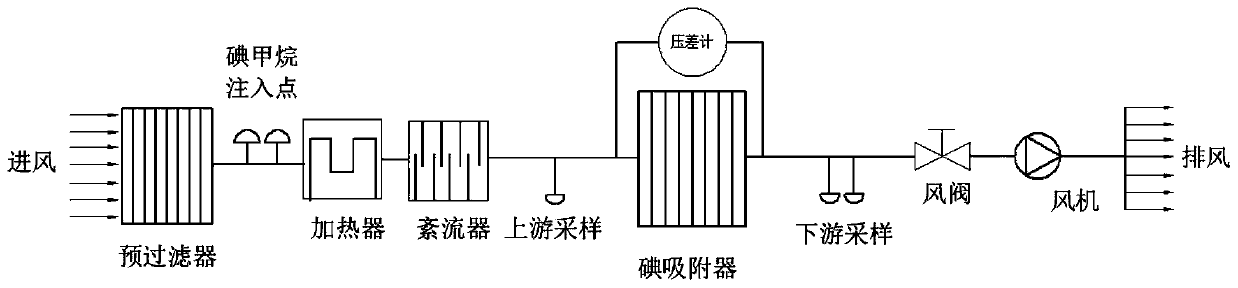

Method used

Image

Examples

Embodiment 1

[0041] The mixed gas of air and stable methyl iodide is passed through the activated carbon adsorber, wherein the concentration of stable methyl iodide in the mixed gas is 50 ppm; the loading capacity of activated carbon in the activated carbon adsorber is 30 kg. Adding stable methyl iodide to the mixed gas is beneficial to make the final test results more accurate.

[0042] The conditions for the mixed gas of air and stable methyl iodide to pass through the activated carbon adsorber are: temperature 25° C., relative humidity 35%, and mixed gas flow rate 1.2 cm / s.

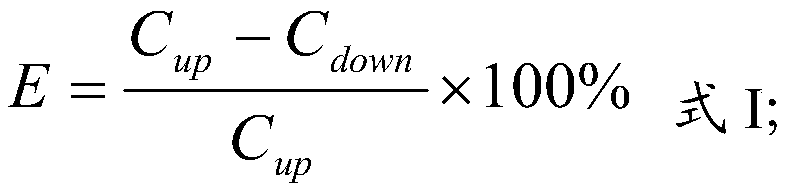

[0043]Before the mixed gas passes through the activated carbon adsorber, after the pulse injection of methyl iodide with a total concentration of 500ppm (the sum of the stable methyl iodide concentration and the pulse injected methyl iodide concentration), immediately sample the downstream of the activated carbon adsorber, and the downstream sampling time is 3min / The sample volume is 0.5L / piece, and the total numb...

Embodiment 2

[0048] The mixed gas of air and stable methyl iodide is passed through the activated carbon adsorber, wherein the concentration of stable methyl iodide in the mixed gas is 5 ppm; the loading capacity of activated carbon in the activated carbon adsorber is 40kg. Adding stable methyl iodide to the mixed gas is beneficial to make the final test results more accurate.

[0049] The conditions for the mixed gas of air and stable methyl iodide to pass through the activated carbon adsorber are: temperature 45° C., relative humidity 40%, and mixed gas flow rate 1.2 cm / s.

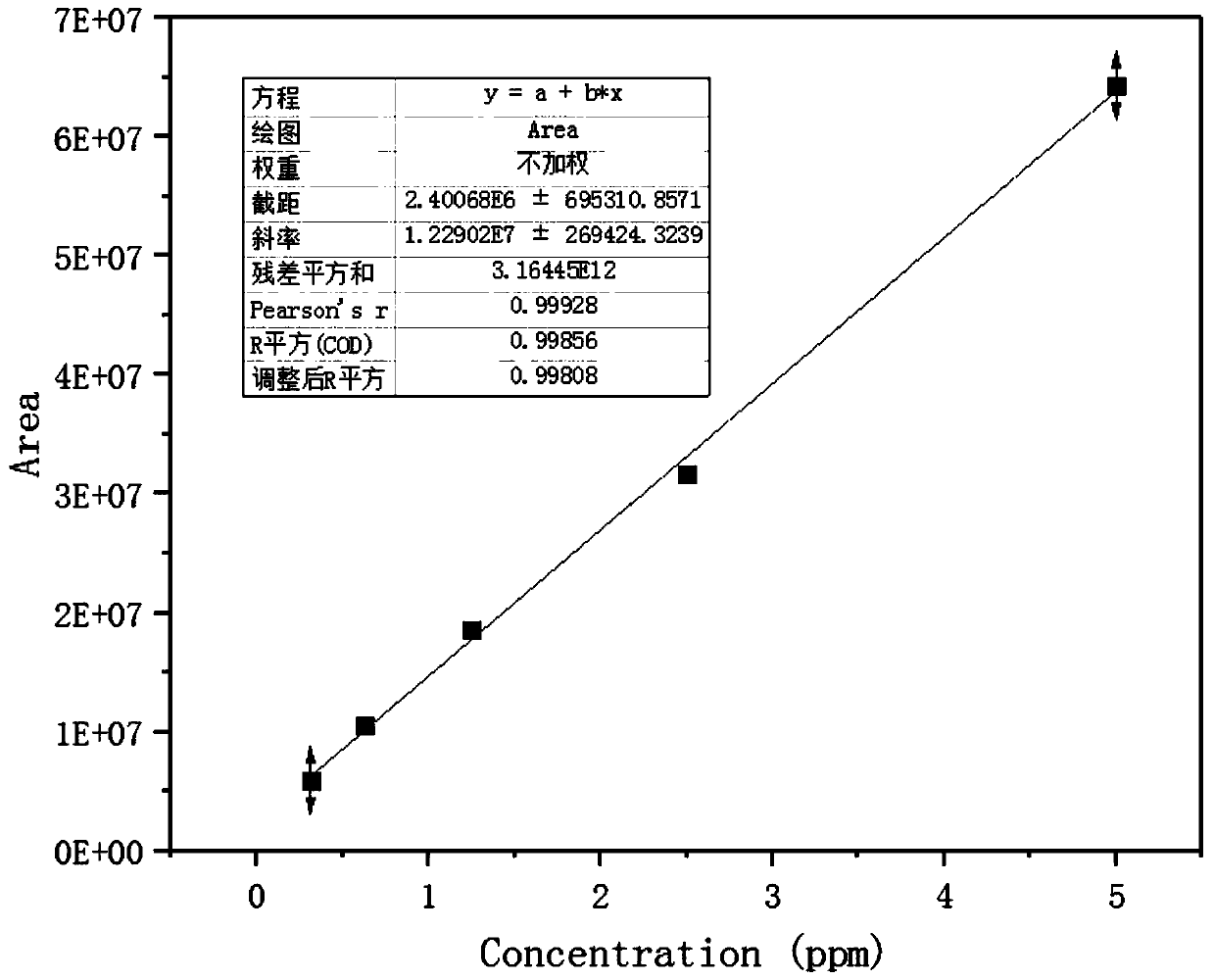

[0050] Before the mixed gas passes through the activated carbon adsorber, continuously inject methyl iodide for 20 minutes, and continue sampling upstream before the activated carbon adsorber is adsorbed and downstream after the activated carbon adsorber is adsorbed. For 60 minutes, each collected sample is tested by gas chromatography. The gas chromatography test conditions are: the temperature of the injection port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com