Perovskite type electroluminescent device and preparation method thereof

An electroluminescent device, perovskite-type technology, applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of unbalanced injection and transport of electrons and holes, and improve the probability of injection and transport , The effect of improving external quantum conversion efficiency and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

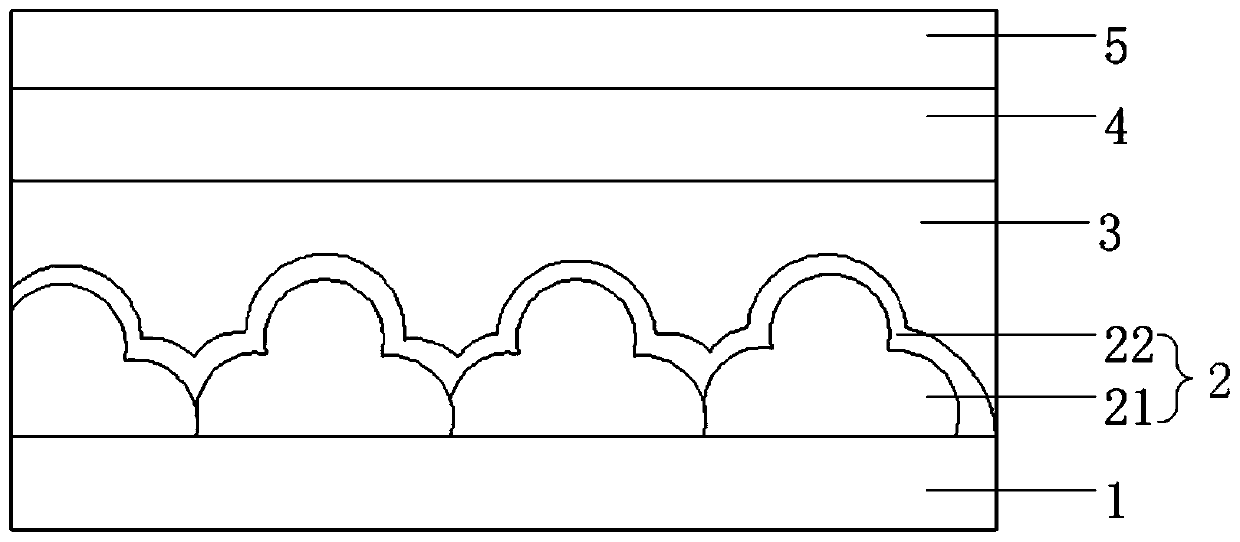

[0031] This embodiment provides a perovskite electroluminescence device, please refer to figure 1 , figure 1 Shown is a schematic cross-sectional view of the perovskite electroluminescent device provided in this embodiment, including an anode layer 1 , a hole transport layer 2 , a light emitting layer 3 , an electron transport layer 4 and a cathode layer 5 arranged in sequence. The hole transport layer 2 is disposed on the anode layer 1 , the light emitting layer 3 is disposed on the hole transport layer 2 , the electron transport layer 4 is disposed on the light emitting layer 3 , and the cathode layer 5 is disposed on the electron transport layer 4 .

[0032] In specific implementation, the anode layer 5 can be made of indium tin oxide (ITO, Indium Tin Oxides) or indium zinc oxide (IZO, Idium Zinc Oxides) or indium gallium zinc oxide (IGZO, Indium Gallium Zinc Oxides), etc., here No limit.

[0033] The light-emitting layer 3 is a light-emitting material with a perovskite s...

Embodiment 2

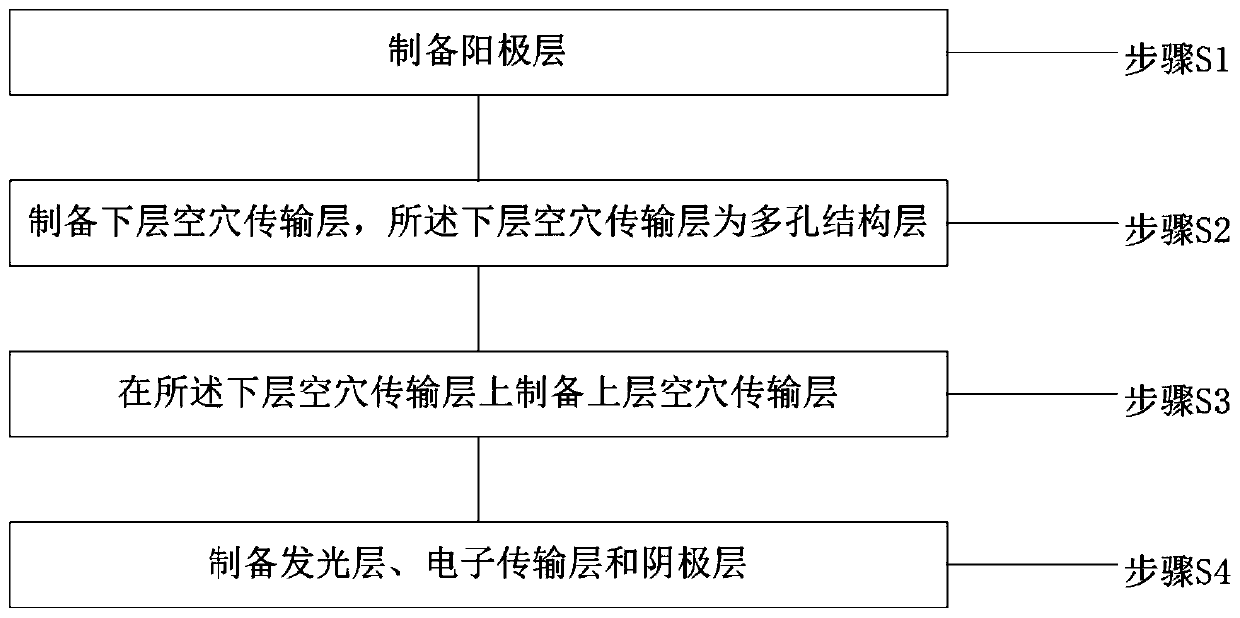

[0039] This embodiment provides a method for preparing the perovskite-type electroluminescent device described in Embodiment 1, please refer to figure 2 , figure 2 Shown is the flowchart of the preparation method of the perovskite-type electroluminescent device provided in this embodiment, including the following steps:

[0040] Step S1: preparing an anode layer;

[0041] Step S2: preparing the lower hole transport layer, the lower hole transport layer is a porous structure layer;

[0042] Methods for preparing the lower hole transport layer include spin coating, etching or printing.

[0043] Step S3: preparing an upper hole transport layer on the lower hole transport layer;

[0044]The lower hole transport layer is annealed first, and then the upper hole transport layer is prepared. The method for preparing the upper hole transport layer includes spin coating, evaporation or sputtering.

[0045] Step S4: Prepare the light-emitting layer, the electron transport layer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com