P5+, Al3+ and B3+ ions co-doped K6Si2O7 potassium fast ion conductor and preparation method thereof

A technology of ionic conductors and ions, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, and electrolyte battery manufacturing, etc., to achieve the effect of reducing migration activation energy and reducing grain boundary voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

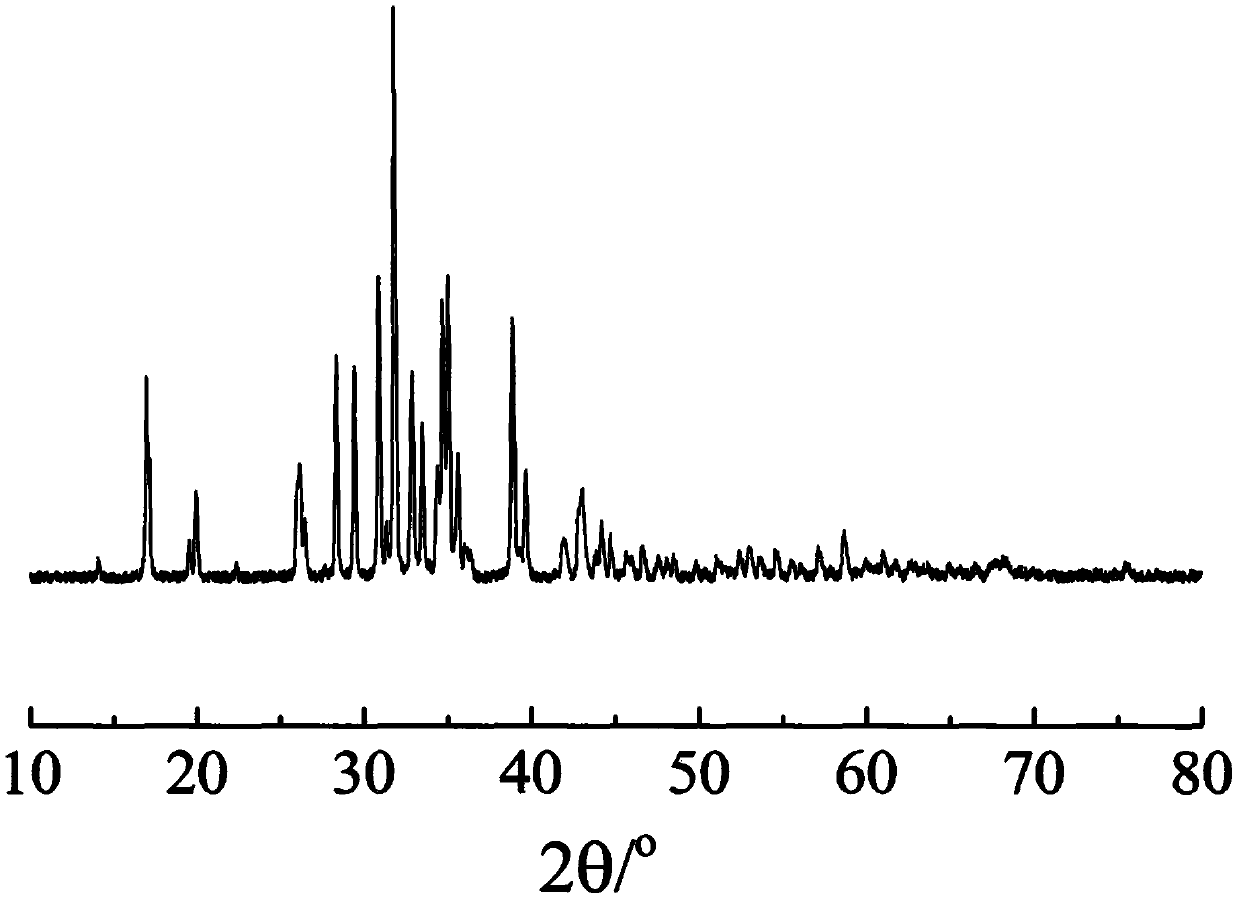

Method used

Image

Examples

Embodiment 1

[0011] Example 1: K 2 CO 3 : NH 4 h 2 PO 4 : Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.08 B 0.05 Al 0.05 P 0.02 Si 1.88 o 7 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 4.5%, in ball mill with the rotating speed ball mill of 110 rev / mins 16 hours, after ball mill finishes, in 65 ℃ of vacuum ovens (gas pressure in oven is at 5 Pa) for 2 hours, take it out and re-grind it in an agate mortar for 12 minutes, heat up the ground powder to 460°C in an air atmosphere at a rate of 6°C / min and keep it warm for 3 hours, then cool it with the furnace; The powder was ground again in an agate mortar for 10 minutes, and the ground powder was heated up to 760 °C at a rate of 5 °C / min in the air atmosphere for 10 hours and then cooled with the furnace; after grinding, it was oxidized in 0.1M hydrogen After soaking in sodium solution for 6 minutes, filter, dry and press at 1×10 7 Pressed into thin slice...

Embodiment 2

[0012] Example 2: K 2 CO 3 : NH 4 h 2 PO 4 : Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.13 B 0.09 Al 0.09 P 0.05 Si 1.77 o 7 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 9%, in ball mill with the rotating speed ball mill of 450 rev / mins 45 hours, in 110 ℃ of vacuum ovens (gas pressure in the oven is in the oven after ball milling finishes) 20Pa) for 9 hours, take it out and re-grind in an agate mortar for 30 minutes, the ground powder is heated to 550°C at a rate of 30°C / min in an air atmosphere and then cooled with the furnace for 10 hours; The powder was ground again in an agate mortar for 30 minutes, and the ground powder was heated to 845 °C at a rate of 15 °C / min in the air atmosphere for 19 hours and then cooled with the furnace; after grinding, it was oxidized in 0.3M hydrogen After soaking in sodium solution for 12 minutes, filter, dry and press in a 7×10 7 Pressed into thin sli...

Embodiment 3

[0013] Example 3: K 2 CO 3 : NH 4 h 2 PO 4 : Al 2 o 3 : SiO 2 :B 2 o 3 According to K 6.12 B 0.07 Al 0.08 P 0.03 Si 1.82 o 7 The ratio of the stoichiometric molar ratio is evenly mixed, adding quality is the dehydrated alcohol of mixture quality 5%, in ball mill with the rotating speed ball mill of 300 rev / mins 30 hours, after ball mill finishes, in 80 ℃ of vacuum ovens (gas pressure in oven is at 15Pa) for 7 hours, take it out and re-grind in an agate mortar for 20 minutes, and the ground powder is heated to 500°C at a rate of 20°C / min in an air atmosphere and then cooled with the furnace for 7 hours; The powder was ground again in an agate mortar for 20 minutes, and the ground powder was heated to 800°C at a rate of 10°C / min in the air atmosphere and kept for 15 hours, then cooled with the furnace; after grinding, it was oxidized in 0.2M hydrogen After soaking in sodium solution for 10 minutes, filter, dry and place in a press at 5×10 7 Press it into thin sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com