Array reflection type microscopic image acquisition system

A microscopic image and acquisition system technology, applied in microscopes, image communications, and components of television systems, etc., can solve the problems of complex imaging process of large samples, difficulty in meeting the needs of microscopic inspection of semiconductor and biological samples, and high cost , to achieve high information collection efficiency and scanning efficiency, and to improve the efficiency of microscopic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

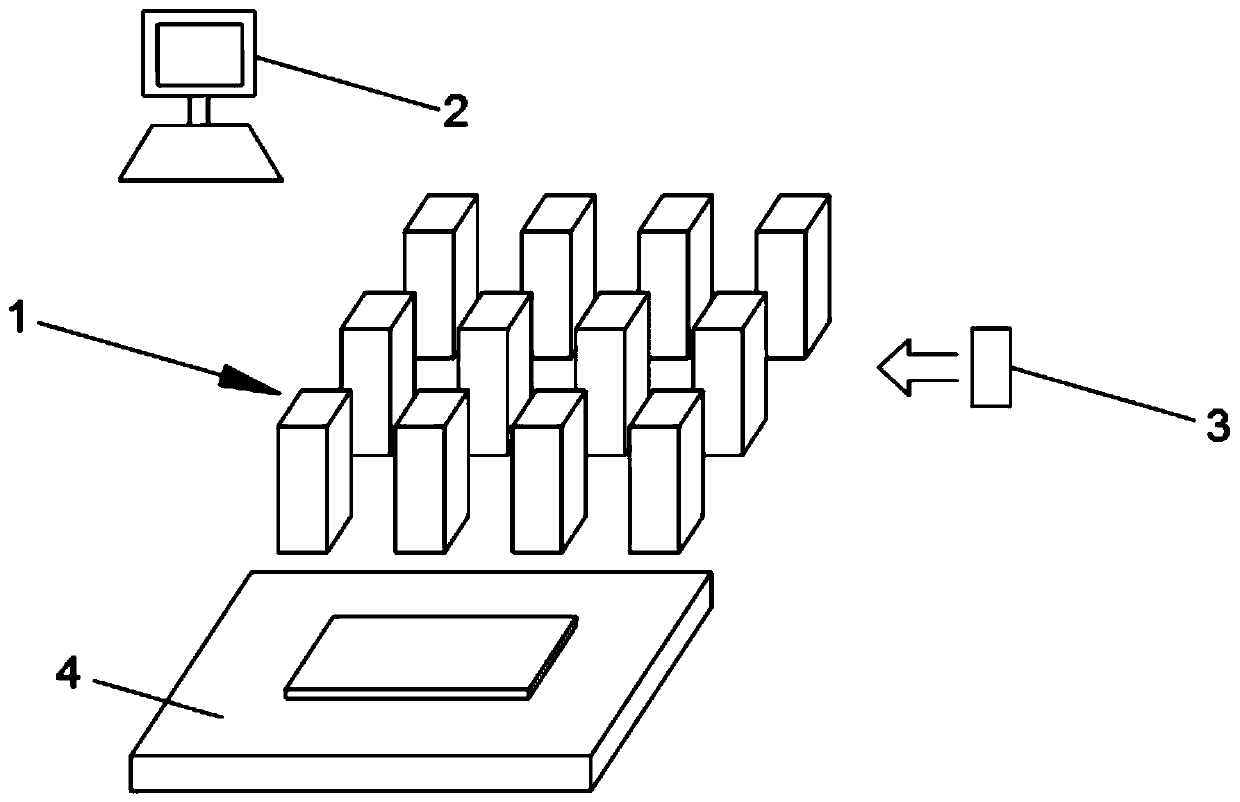

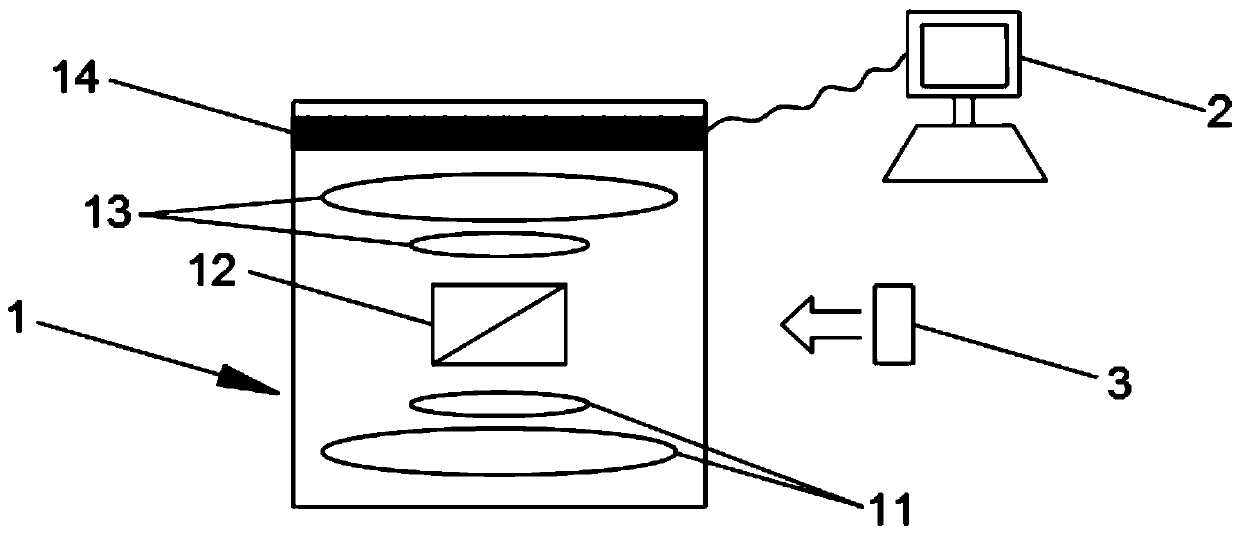

[0031] Embodiment 1: An array reflection type microscopic image acquisition system, such as figure 1 with figure 2 As shown, it includes a microscopic camera module array 1 and a receiving end 2. The microscopic camera module array is located directly above the sample stage 4;

[0032] The micro camera module array includes a plurality of micro camera modules distributed in an array, each of the micro camera modules includes a first lens group 11, a reflective lighting structure 12, an excitation light source 3, and a second lens group 13 and the image sensor 14, the first lens group and the second lens group are symmetrically arranged, the reflective lighting structure is located between the first lens group and the second lens group, the first lens The group is located between the reflective illumination structure and the sample stage, the second lens group is located between the reflective illumination structure and the image sensor, and the image sensor is electrically connec...

Embodiment 2

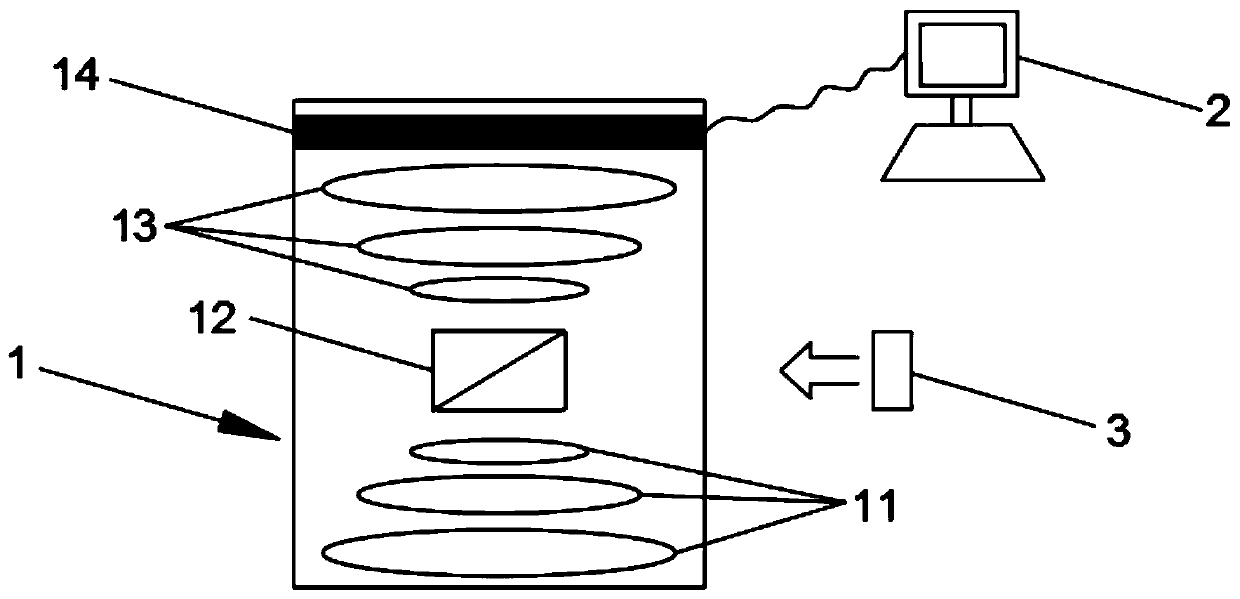

[0043] Embodiment 2: An array reflection type microscopic image acquisition system, such as figure 1 with image 3 As shown, the second lens group includes three microlenses, the size of the microlens close to the image sensor is the largest, and the size of the microlens far away from the image sensor is the smallest; the first lens group includes three microlenses , The size of the microlens close to the image sensor is the smallest, and the size of the microlens far away from the image sensor is the largest.

Embodiment 3

[0044] Embodiment 3: An array reflection type microscopic image acquisition system, such as figure 1 with Figure 4 As shown, the second lens group includes three microlenses, the size of the microlens close to the image sensor is the largest, and the size of the microlens far away from the image sensor is the smallest; the first lens group includes two microlenses , The size of the microlens close to the image sensor is the smallest, and the size of the microlens far away from the image sensor is the largest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com