Efficient chemical reaction kettle

A technology for chemical reaction and reactor body, applied in the field of high-efficiency chemical reactors, can solve the problems of slow reaction efficiency of the reactor, inconvenient material discharge, etc., and achieve the effect of increasing the stirring effect and the effect of fast reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

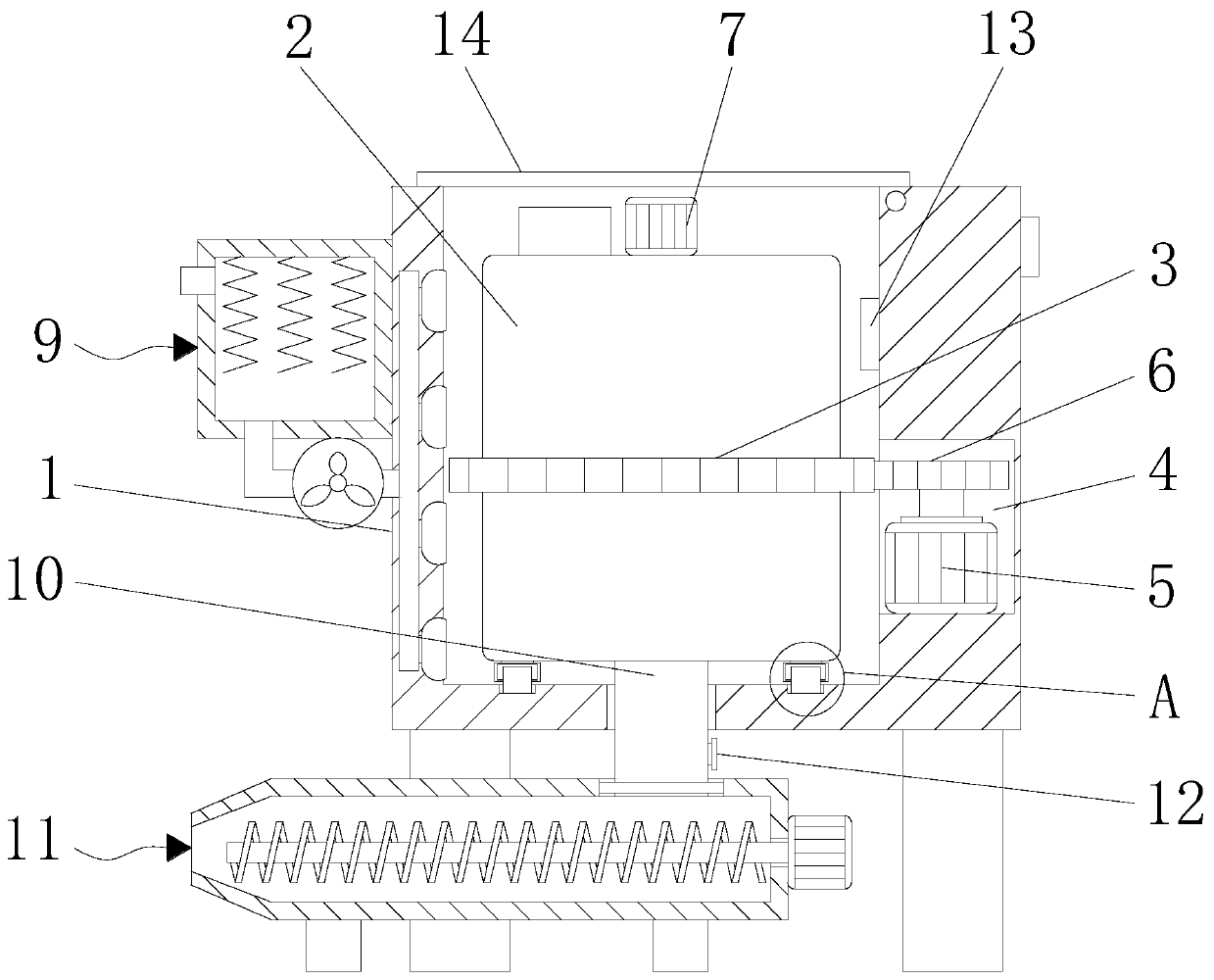

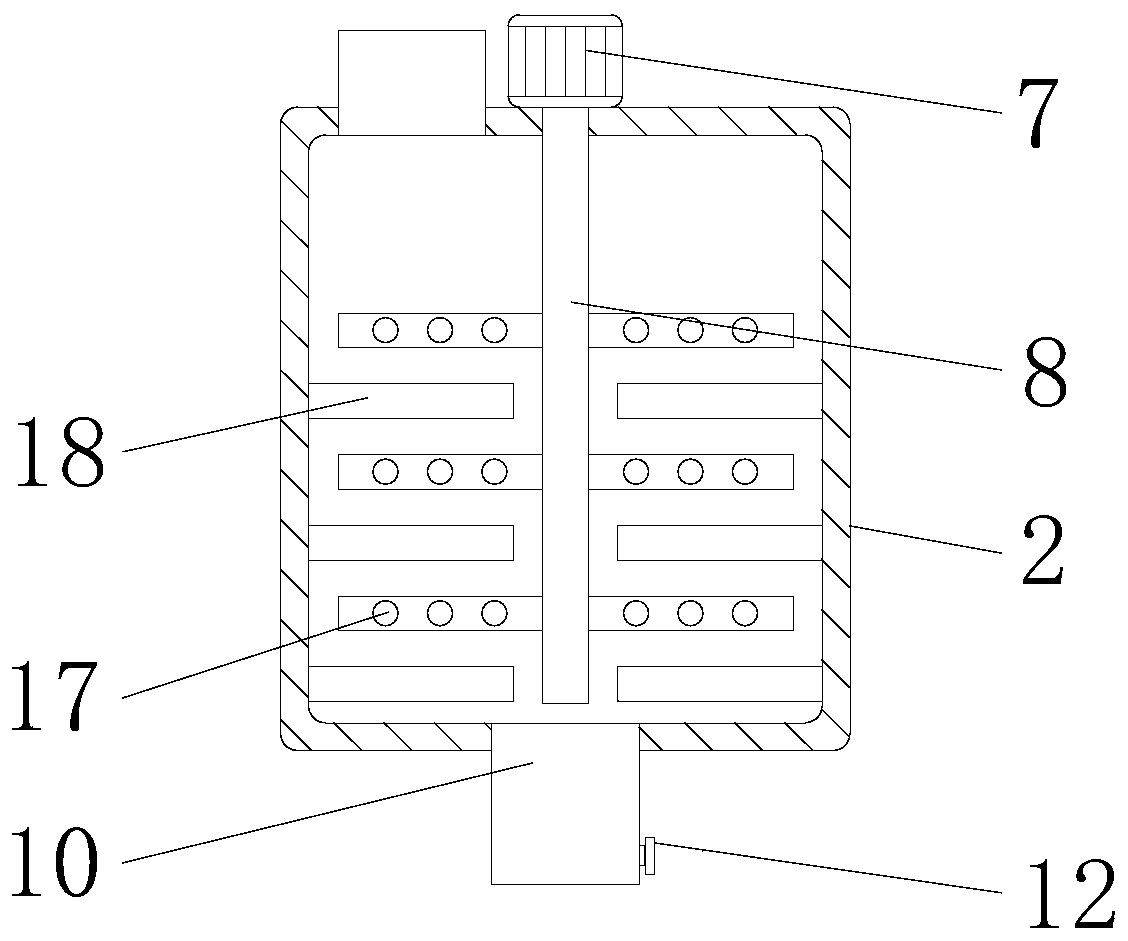

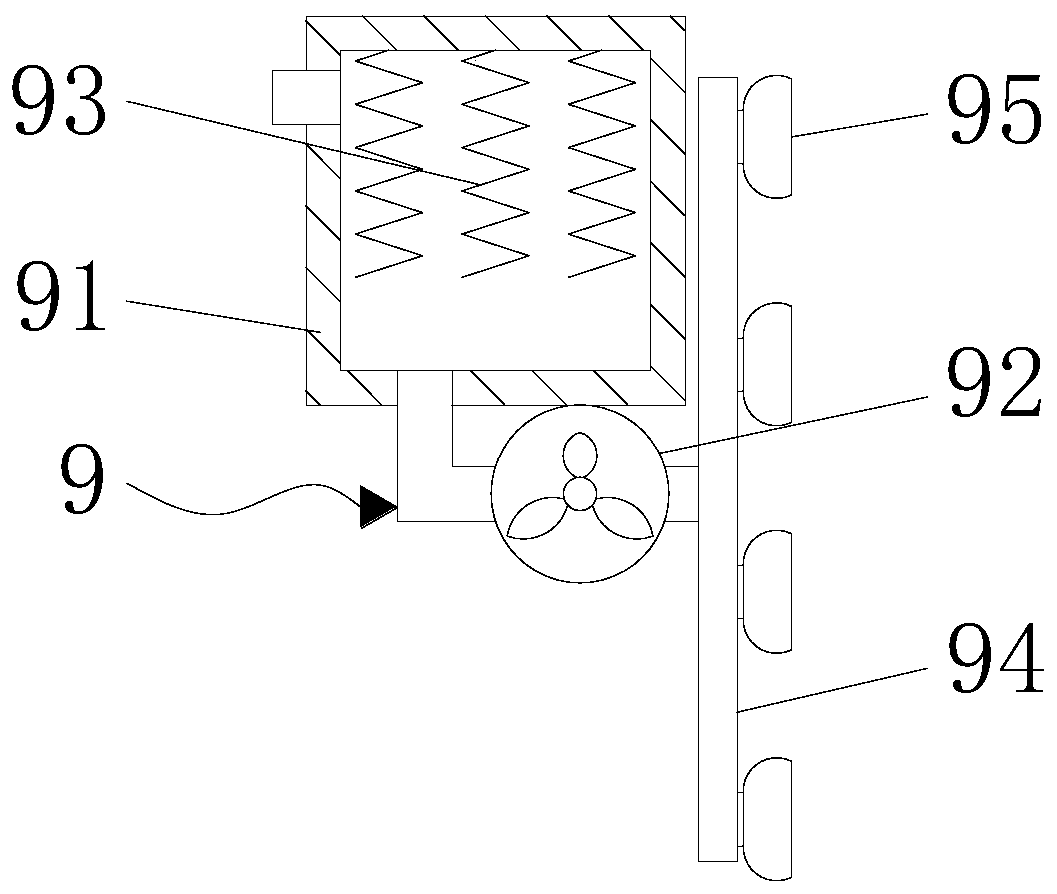

[0022] see Figure 1-5 , a high-efficiency chemical reaction kettle, including a box body 1, a temperature sensor 13 is fixedly connected inside the box body 1, through the temperature sensor 13, the effect of temperature detection in the box body 1 is achieved, and the effect of mixing is avoided. The right side of the top of the body 1 is movably connected with a cover plate 14 through a rotating shaft. Through the cover plate 14, the effect of sealing the box body 1 is achieved to avoid heat dissipation. The bottom of the box body 1 and the discharge mechanism 11 are equipped with movable Mechanism, the moving structure includes rollers installed on both sides of the bottom of the box 1 and a motor installed on the left side of the bottom of the box 1. The moving method is: start the motor, and the output end of the motor drives the rollers on both sides of the bottom of the box 1 through a belt. Rotate, so as to realize the movement of the box body 1, and the motor can be ...

Embodiment 2

[0024] see Figure 1-5, a high-efficiency chemical reaction kettle, including a box body 1, a temperature sensor 13 is fixedly connected inside the box body 1, through the temperature sensor 13, the effect of temperature detection in the box body 1 is achieved, and the effect of mixing is avoided. The right side of the top of the body 1 is movably connected with a cover plate 14 through a rotating shaft. Through the cover plate 14, the effect of sealing the box body 1 is achieved to avoid heat dissipation. The bottom of the box body 1 and the discharge mechanism 11 are equipped with movable Mechanism, the moving mechanism is the rollers installed on both sides of the bottom of the box body 1, and its movement method is: people push the box body 1, so that the rollers rotate and drive the box body 1 to move, and the inside of the box body 1 is provided with a reaction kettle body 2 , the left side of the top of the reactor body 2 is connected with a filling pipe, both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com