Preparation method of modified MoS2/CdS-based composite photoelectrode material and application thereof

A photoelectrode, mos2 technology, applied in catalyst activation/preparation, electrodes, chemical instruments and methods, etc., can solve the problems of low utilization rate of visible light, low catalytic activity, unstable hydrogen evolution performance, etc., and achieve good catalytic activity and hydrogen evolution performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

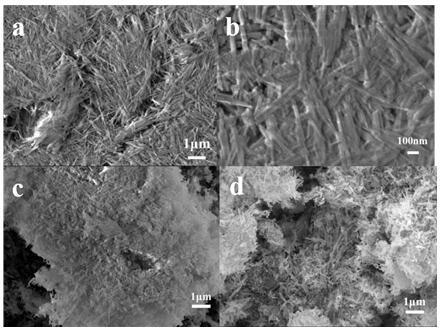

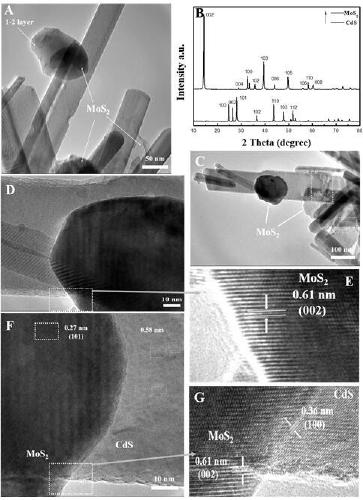

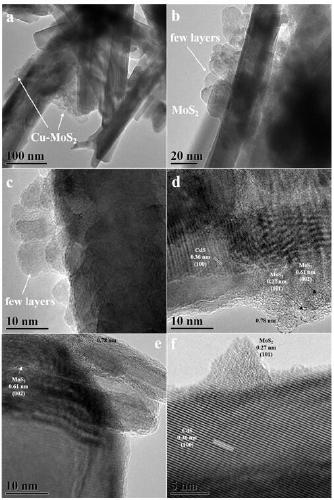

[0034] Example 1: (Cu-doped CdS / MoS 2 Preparation method and application of matrix composite materials)

[0035] 0.9995 g Cd(NO 3 ) 2 4H 2 O was dissolved in 60 mL distilled water, stirred for 30 min until uniform, according to the 3 ) 2 4H 2 O molar ratio is 10:0.7:30 Weigh 0.0311 g CuCl respectively 2 , 0.6942 g thiourea, was added to the above solution, magnetically stirred for 3 h, ultrasonic 0.5 h. Then the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, heated in water at 160 °C for 16 h, cooled to room temperature after the end of the water heat, soaked in 20 mL of ethanol and water for 1 h, ultrasonicated for 30 min, and then centrifuged , repeated 5 times until no Cl -1 After detection, a golden yellow precipitate was obtained, which was dried in a drying oven at 80 °C and then ground to obtain Cu-doped CdS.

[0036] Weigh 1 g of the above Cu-CdS into a 100 mL beaker, add 60 mL of distilled water, and sonicate in a...

Embodiment 2

[0039] Example 2: (MoS 2 / Fe-CdS composite material preparation method and application)

[0040] 0.9995 g Cd(NO 3 ) 2 4H 2 O was dissolved in 60mL distilled water, stirred for 30 min until the solution was uniform, and 3 ) 2 4H 2 The O molar ratio is 10:0.7:30 and weighs 0.0293 g FeCl 2 , 0.6942g thiourea, added to the above solution, magnetically stirred for 3 h, ultrasonic 0.5 h. Then the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, heated in water at 160 °C for 16 h, cooled to room temperature after the end of the water heat, soaked in 20 mL of ethanol and water for 1 h, ultrasonicated for 30 min, and then centrifuged , repeated 5 times until no Cl - Until it is detected, dry the golden precipitate in a drying oven at 80°C and grind it to obtain Fe-CdS.

[0041] Weigh 1 g of the above-mentioned Fe-CdS into a 100 mL beaker, add 60 mL of distilled water, and ultrasonically treat it in an ultrasonic cleaner for 10 min to...

Embodiment 3

[0044] Example 3: (MoS 2 / Co-CdS composite material preparation method and application)

[0045] 0.9995 g Cd(NO 3 ) 2 4H 2 O was dissolved in 60 mL of distilled water, and stirred for 30 min until the solution was uniform. 3 ) 2 4H 2 The O molar ratio is 10:0.7:30 and weighs 0.0228 g CoCl respectively 2 , 0.6942 g of thiourea was added to the above solution, magnetically stirred for 3 h, and ultrasonicated for 0.5 h. Then, the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, heated in water at 160 °C for 16 h, cooled to room temperature after the end of the water heat, soaked in 20 mL of ethanol and water for 1 h, ultrasonicated for 30 min, and then Centrifuge and repeat 5 times until Cl-free -1 until checked out. A golden yellow precipitate will be obtained, which is dried in an oven at 80 °C and then ground to obtain Co-CdS.

[0046] Weigh 1 g of the above-mentioned Co-CdS into a 100 mL beaker, add 60 mL of distilled wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com