Sand discharge equipment of anaerobic fermentation tank

An anaerobic fermenter and fermenter technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to solve the problem of sand settling, hindering the discharge of the sand settling outlet, and inability to discharge, etc. Achieve the effect of avoiding excessive sand deposition, broad application prospects and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

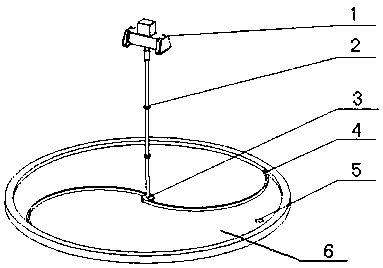

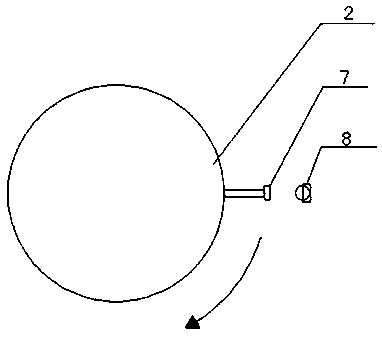

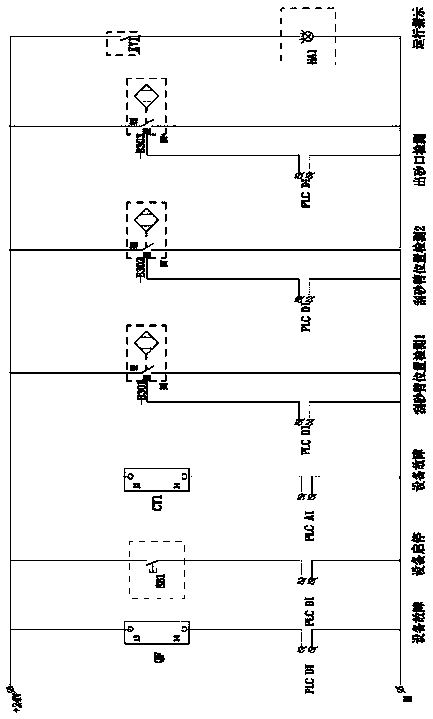

[0027] Such as Figure 1-4 As shown, an anaerobic fermenter row sand settling equipment includes a drive part 1 located outside the fermenter 6, the drive part 1 is located at the center of the top of the fermenter 6, and the bottom of the fermenter 6 forms a sand discharge port 5, so The driving part 1 is connected with the sand scraping arm fixing seat 3 at the bottom of the fermentation tank 6 through the rotating shaft 2, and the sand scraping arm 4 is installed on the sand scraping arm fixing seat 3; the sand scraping arm 4 at the bottom of the fermentation tank 6 of the present invention is rotated After the sand discharge is completed, the sand scraping arm 4 is driven by the transmission shaft 2 at the center of the fermenter 6 , and the power source of the transmission shaft 2 comes from the drive unit 1 .

[0028] The running position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com