Three-dimensional digital laser repairing device and method of steel rail

A laser repair and rail technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as shortening the service life of the rail, increasing the maintenance cost, affecting the rail flaw detection, etc., to improve the service life, improve the degree of automation and The effect of productivity, improved machining accuracy and quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0031] Although the present invention has been described with reference to exemplary embodiments, it should be understood that the present invention is not limited to the specific embodiments described and shown in detail herein, and that it is possible for those skilled in the art to do so without departing from the scope defined by the claims. Personnel may make various changes to the exemplary embodiments described.

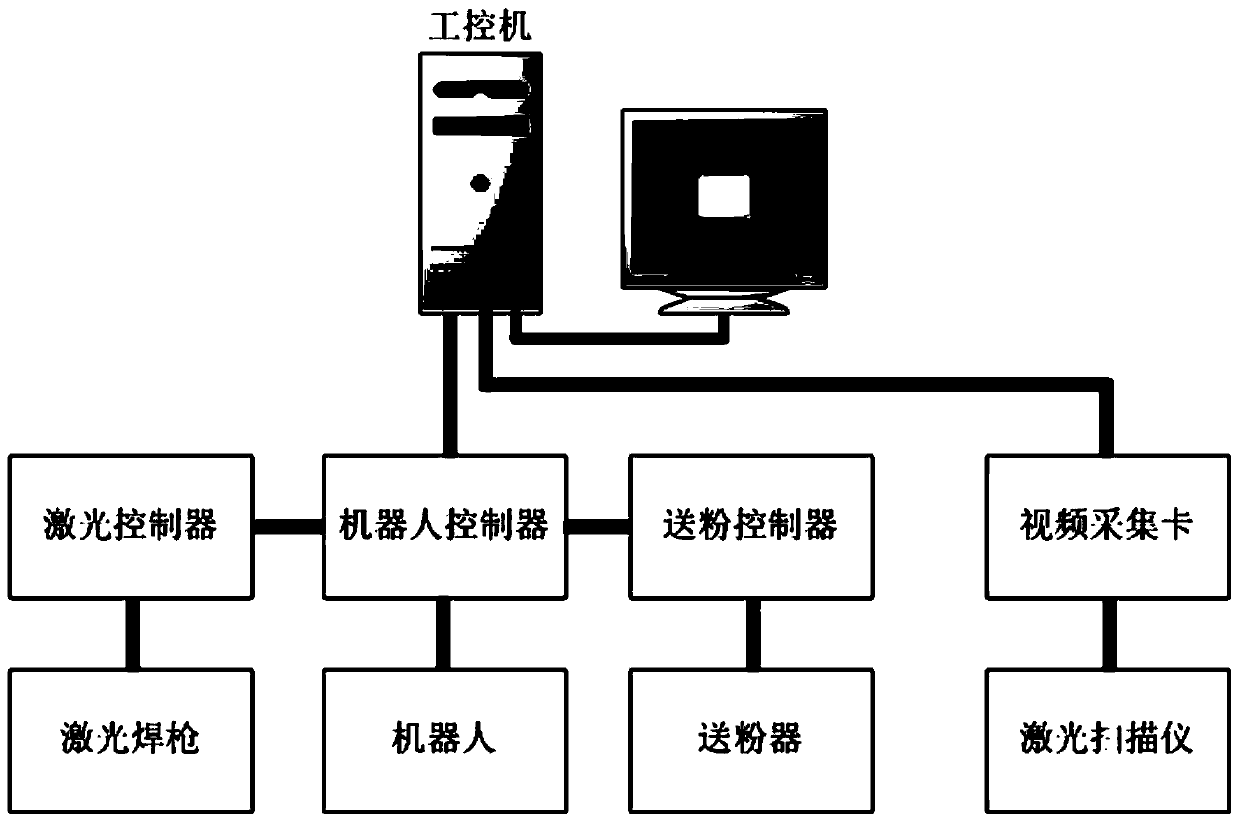

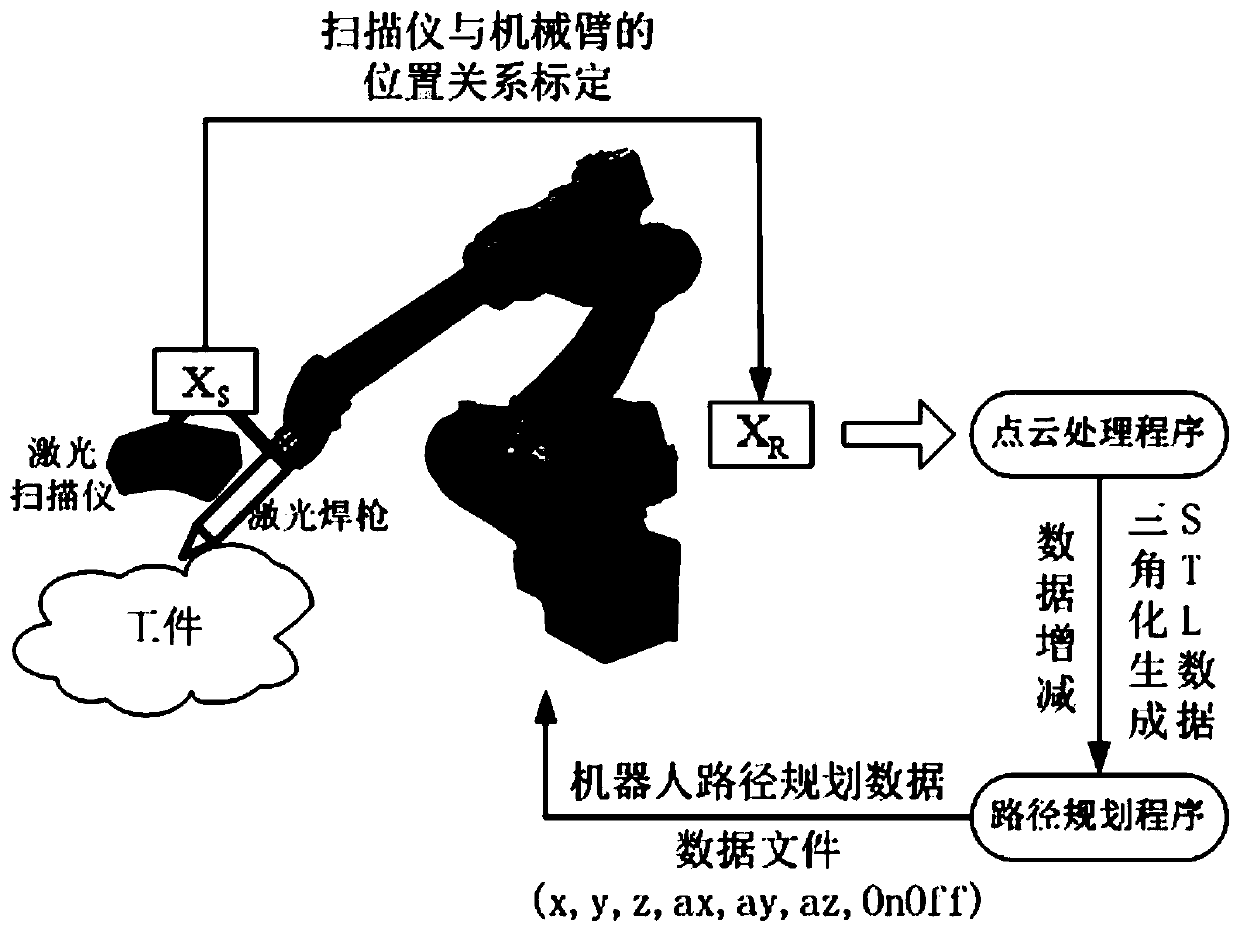

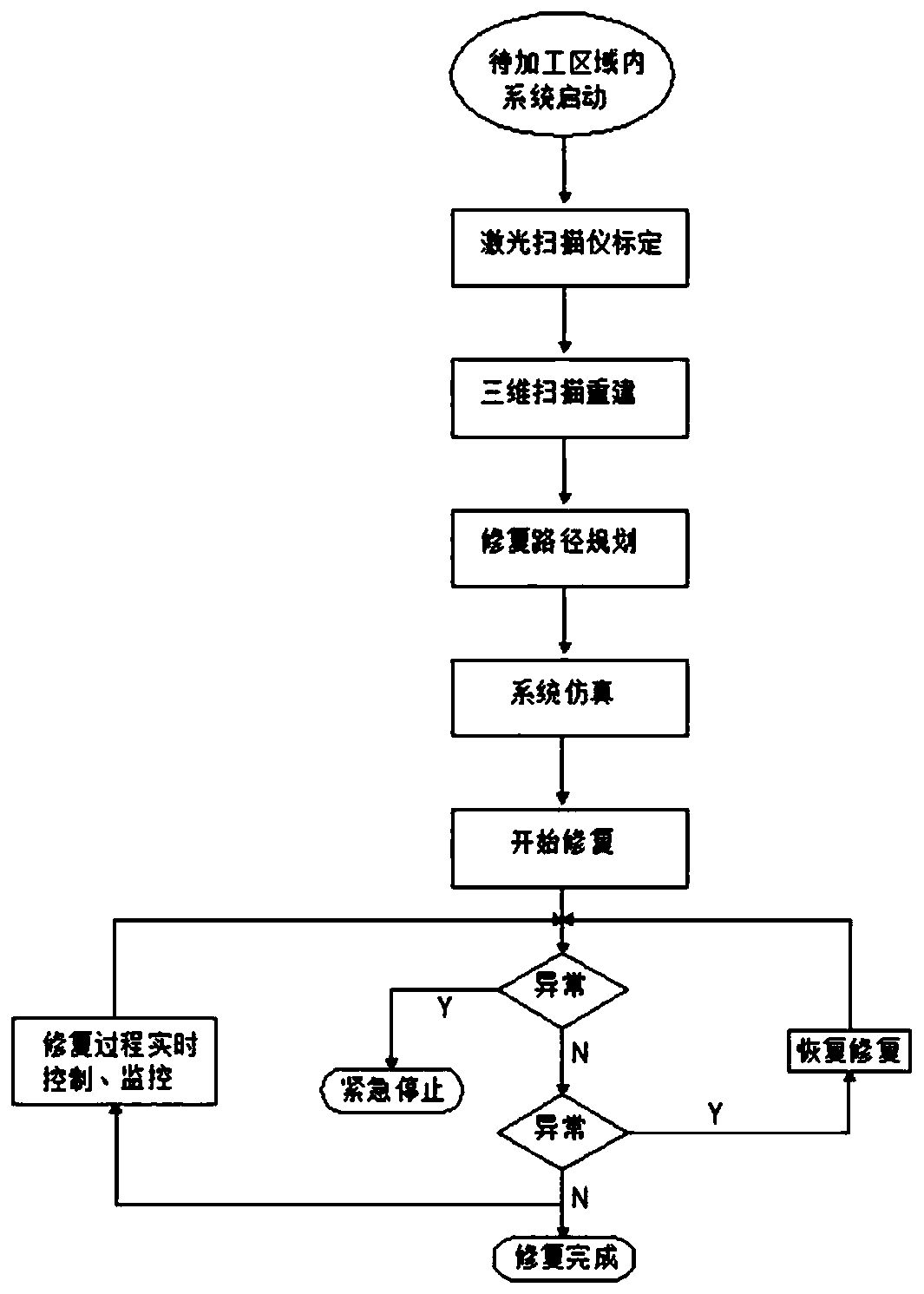

[0032] Attached below figure 1 to attach Figure 4 The technical solutions of the embodiments of the present invention will be described in detail. The three-dimensional digital rail laser repair device and repair method provided by the embodiments of the present invention inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com