Hydrogel coating and production method and application thereof

A technology of hydrogel and coating, applied in the direction of coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] The preparation method of embodiment 1 hydrogel coating

[0107] The hydrogel coating is obtained by chemical cross-linking on the basis of polyelectrolyte multilayer films. The preparation of polyelectrolyte multilayer films adopts the method of layer-by-layer self-assembly, using the electrostatic attraction and hydrogen bonding of polyelectrolytes to make it fit together.

[0108] Prepare polyethyleneimine, poly(4-styrene sulfonate sodium) (PSS), and polyallylamine hydrochloride (PAH) solutions with a concentration of 1 g / L in deionized water, and then add Sodium chloride, so that the concentration is 0.5mol / L. Use deionized water to prepare phosphate buffer solutions with pH=2.5, 5.0, and 8 concentrations of 0.01 mol / L, and use 0.1 mol / L hydrochloric acid solution and sodium hydroxide solution to control and adjust the pH and ionic strength. Polymethacrylic acid (PMAA) and polyvinylpyrrolidone (PVPON) solutions with a concentration of 0.5 g / L were prepared respect...

Embodiment 2

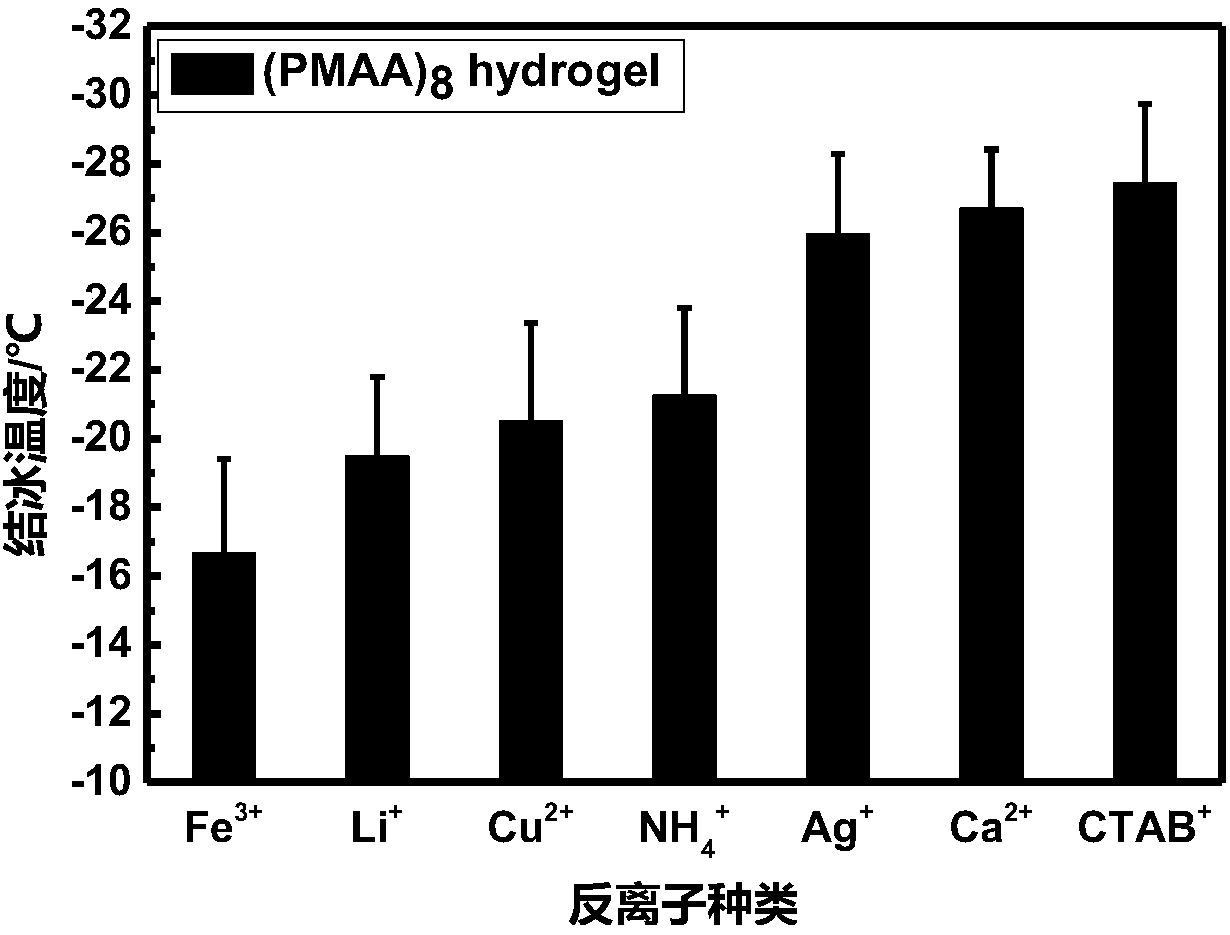

[0117] Embodiment 2 The freezing temperature of water droplets on the surface of the hydrogel coating

[0118] Prepare 7 kinds of 8 layers of coatings " (PMAA) according to the mode of embodiment 1 8 -Li", "(PMAA) 8 -NH 4 ","(PMAA) 8 -Ag", "(PMAA) 8 -Cu", "(PMAA) 8 -Ca", "(PMAA) 8 -Fe", "(PMAA) 8 -CTAB" samples, use a microsampler to drop 9-12 drops of 0.1 μL water on the surface of the sample, and then put the sample into figure 1 In the sandwich structure shown, place it on the cold platform, cool down at a rate of 5°C / min, observe and record the freezing temperature of water droplets, repeatedly measure 100-200 water droplets, calculate the average value, and statistical data ( figure 2 shown). It was found that the maximum difference in freezing temperature of samples with different counter ions was about 10°C; the coating "(PMAA) 8 The freezing temperature of the -CTAB" sample is the lowest compared to the others, at around -24°C.

[0119] It can be seen that b...

Embodiment 3

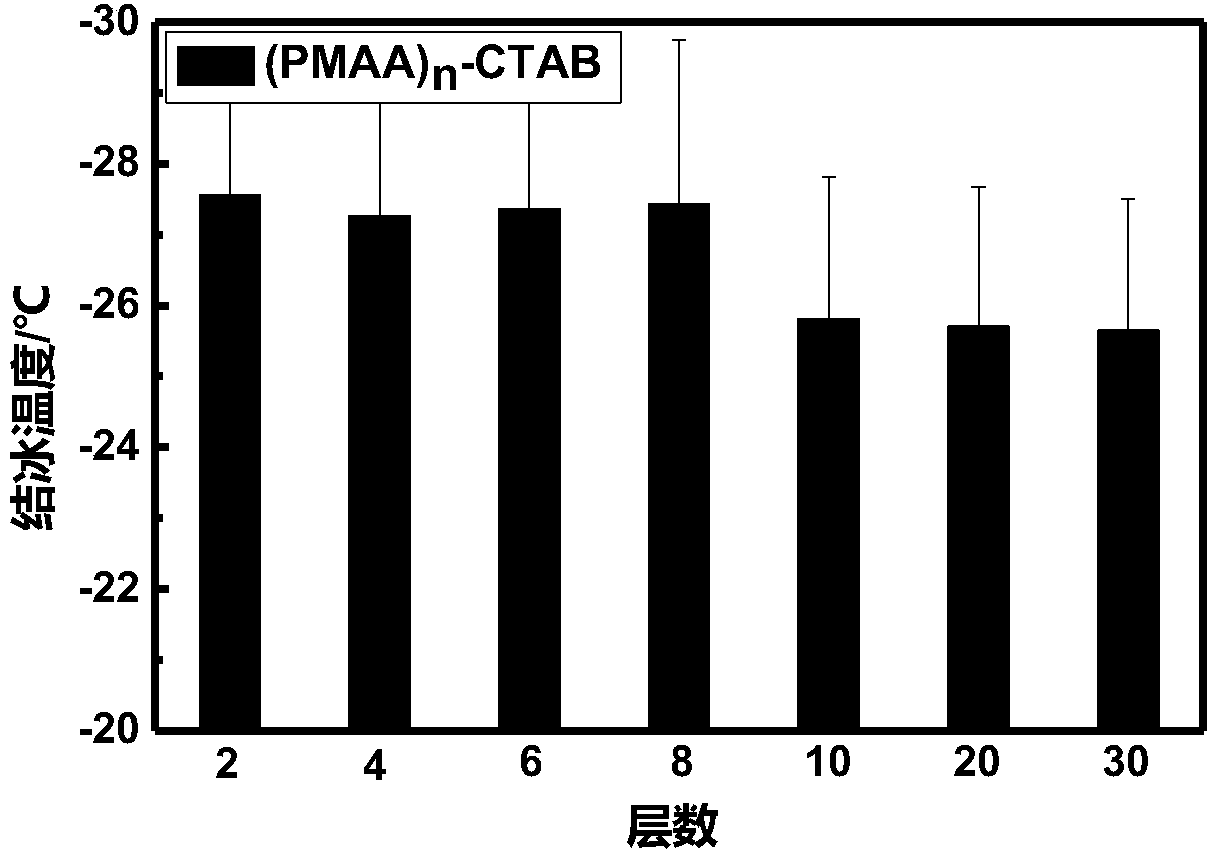

[0120] The influence of embodiment 3 coating thickness on coating freezing temperature

[0121] According to the method of embodiment 1, prepare the hydrogel coating "(PMAA) with cetyltrimethylammonium bromide ion of 7 kinds of thickness 2 -CTAB', '(PMAA) 4 -CTAB', '(PMAA) 6 -CTAB', '(PMAA) 8 -CTAB', '(PMAA) 10 -CTAB', '(PMAA) 20 -CTAB', '(PMAA) 30 -CTAB" samples, use a microsampler to drop 9-12 drops of 0.1 μL water on the surface of the sample, and then put the sample into figure 1 In the sandwich structure shown, place it on a cold platform, cool down at a rate of 5°C / min, observe and record the freezing temperature of water droplets. Record the freezing temperature of the water droplets on each sample, repeatedly measure 100-200 water droplets, calculate the average value, and statistical data ( image 3 shown).

[0122] It was found that: under different thicknesses, the coating "(PMAA) n -CTAB" samples have low freezing temperatures, between -24°C-(-28°C).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com