High-temperature-resistant clean fracturing fluid thickener capable of realizing repeated crosslinking

A technology for cleaning fracturing fluids and thickeners, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, poor temperature resistance, incomplete gel breaking, etc., and achieve high temperature resistance , The effect of increasing construction speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

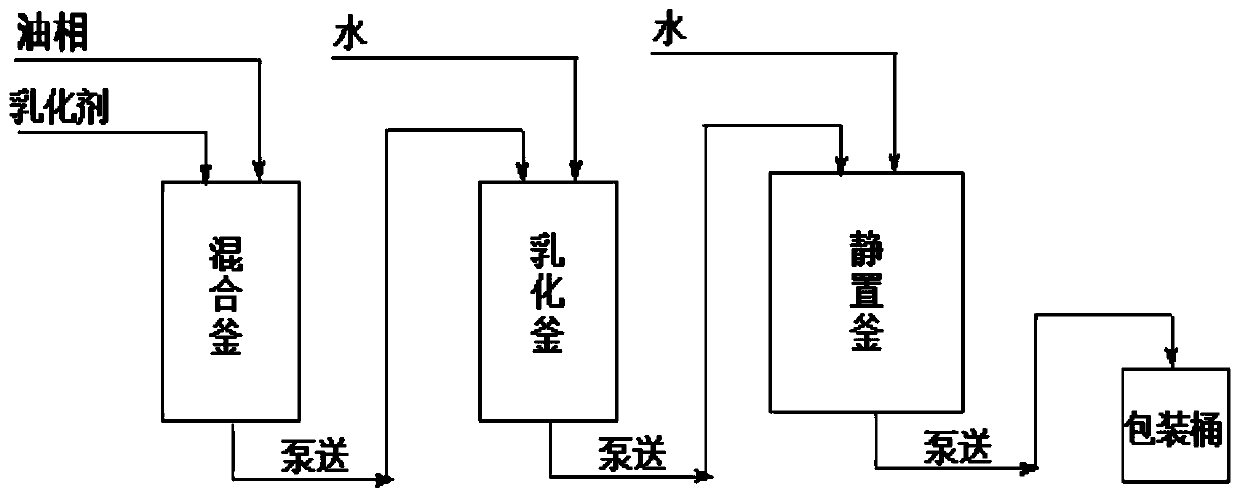

[0024] Such as figure 1 As shown, the present invention provides a kind of high temperature resistant and reusable cross-linking cleaning fracturing fluid thickener, the thickener is made of 50% water, 30% sodium lauryl sulfate, 5% Si Disc 80, 5% Tween 80, 5% organic alcohol, 5% CAB-35.

[0025] The organic alcohol is one of methanol, ethanol, propanol, isopropanol, ethylene glycol and cycloethanol.

[0026] A method for preparing a high-temperature-resistant and repeatable cross-linking cleaning fracturing fluid thickener, the preparation steps are as follows:

[0027] Step 1: Add 30% sodium lauryl sulfate, 5% Span 80, 5% Tween 80, 5% organic alcohol and 5% CAB-35 into the mixing tank for stirring and mixing 45-60 minutes to make a mixture;

[0028] Step 2: Send the homogeneously mixed material into the emulsification tank by pipeline and feeding pump, add an appropriate amount of water, stir and mix for 1.5-2 hours, and make a mixed solution;

[0029] Step 3: Send the mi...

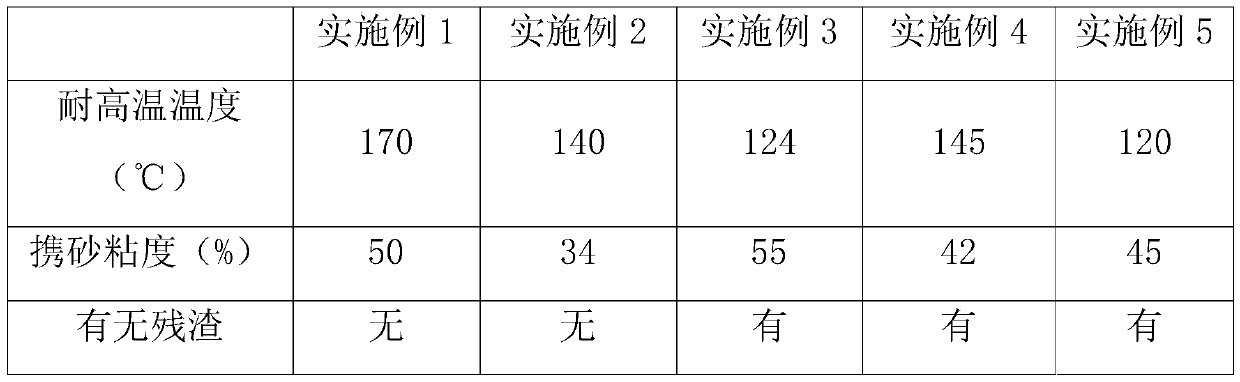

Embodiment 2

[0035] The weight ratio of the thickener raw material is changed to 40% water, 35% sodium lauryl sulfate, 10% Span 80, 5% Tween 80, 5% organic alcohol, 5% CAB-35, and prepare a thickener according to the preparation method of a high-temperature-resistant and repeatable cross-linking cleaning fracturing fluid thickener provided by the present invention.

Embodiment 3

[0037] The weight ratio of the thickener raw material is changed to 45% water, 30% sodium lauryl sulfate, 10% Span 80, 8% Tween 80, 5% organic alcohol, 2% CAB-35, and prepare a thickener according to the preparation method of a high-temperature-resistant and repeatable cross-linking cleaning fracturing fluid thickener provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com