Fabric and preparation method thereof

A technology for fabrics and photosensitizers, applied in the directions of fabrics, textiles, textiles, and papermaking, can solve problems such as inability to exert efficacy, and achieve the effect of improving effective utilization, saving space, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

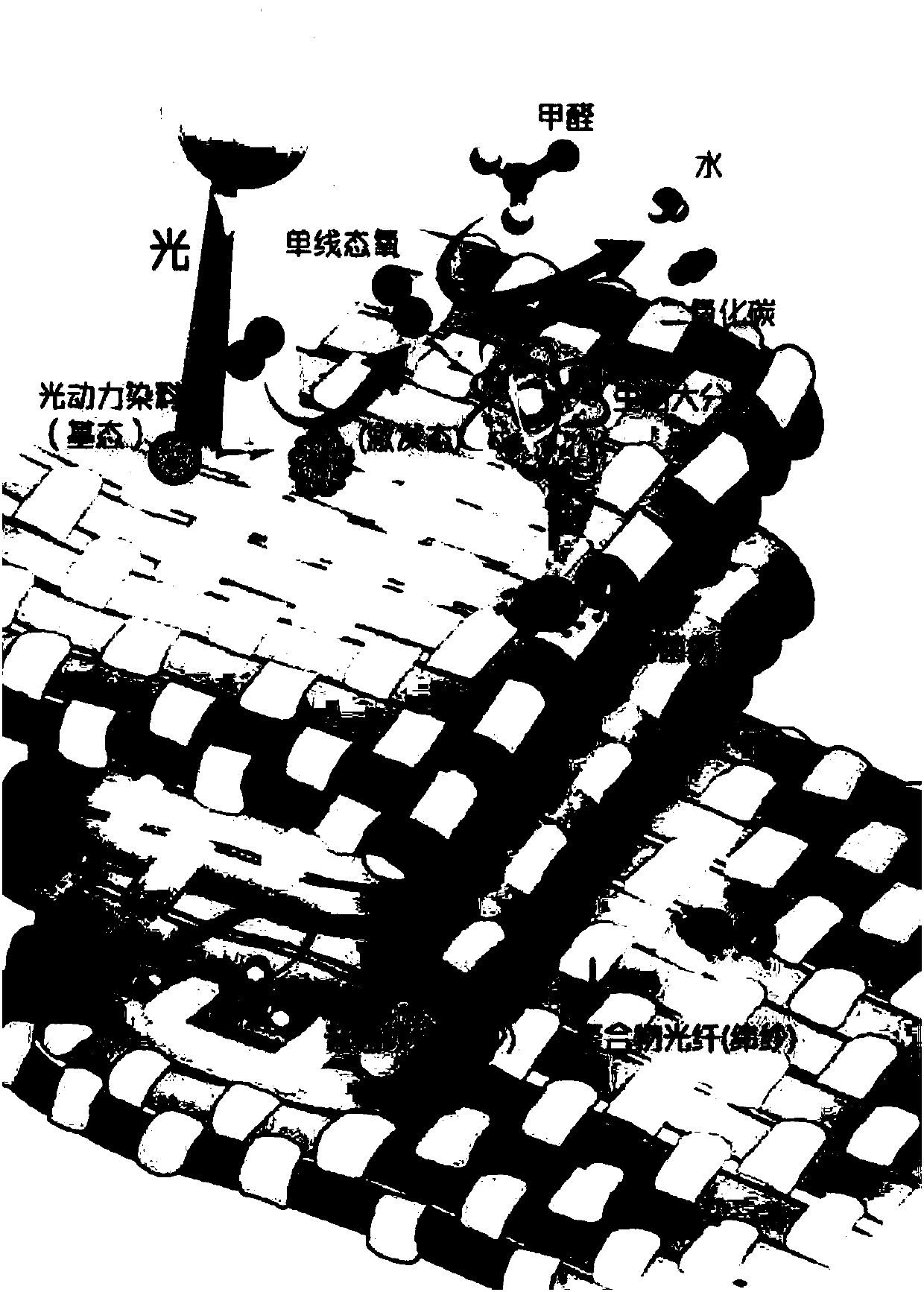

Image

Examples

Embodiment 1

[0035] The weaving process and antibacterial test results of a woven plain wool fabric with polymer optical fibers are as follows:

[0036] (1) The photosensitizer is fixed on the wool yarn by means of dyeing agent, which is woven into the fabric as warp yarn. The concentration of methylene blue dye is 0.5-3% owf, and the temperature is 60℃-140℃.

[0037] (2) The fabric weft yarn is a plastic optical fiber (with a diameter of 0.25 mm or 0.50 mm) with polymethyl methacrylate (PMMA) as the core and fluororesin as the sheath, and ordinary wool yarn or all plastic optical fibers. If there are two kinds of yarns, the interweaving relationship between them is plastic optical fiber: ordinary wool yarn=10:1~1:10.

[0038] (3) Finally, refer to GB / T20944.1~2007 "Evaluation of antibacterial properties of textile materials: Agar plate diffusion method" or GB / T20944.2~2007 "Evaluation of antibacterial properties of textile materials: Absorption method" or GB / T20944. 3~2008 "Evaluation of Antib...

Embodiment 2

[0040] The weaving process and antibacterial test results of a woven plain wool fabric with polymer optical fibers are as follows:

[0041] (1) The photosensitizer is fixed on the wool yarn by means of dyeing agent, which is woven into the fabric as warp yarn. Among them, the methylene blue dye concentration is 0.5-3% owf, the dyeing solution has a pH of 4-5, and the temperature is 80°C to 135°C.

[0042] (2) The fabric weft yarn is a plastic optical fiber (with a diameter of 0.25mm or 0.50mm) with polystyrene (PS) as the core and fluororesin as the sheath, and ordinary wool yarn or all plastic optical fibers. If there are two kinds of yarns, the interweaving relationship between them is plastic optical fiber: ordinary wool yarn=10:1~1:10.

[0043] (3) Finally, refer to GB / T20944.1~2007 "Evaluation of antibacterial properties of textile materials: Agar plate diffusion method" or GB / T20944.2~2007 "Evaluation of antibacterial properties of textile materials: Absorption method" or GB / T...

Embodiment 3

[0045] The weaving process and antibacterial test results of a woven plain wool fabric with polymer optical fibers are as follows:

[0046] (1) The photosensitizer is fixed on the wool yarn by means of dyeing agent, which is woven into the fabric as warp yarn. The methylene blue dye concentration is 0.5-3% owf, the dyeing solution has a pH of 4-5, and the temperature is 70°C to 135°C.

[0047] (2) The fabric weft yarn is a plastic optical fiber (with a diameter of 0.25mm or 0.50mm) with polycarbonate (PC) as the core and fluororesin as the sheath, and ordinary wool yarn or all plastic optical fibers. If there are two kinds of yarns, the interweaving relationship between the two is plastic optical fiber: ordinary wool yarn=1:10~10:1.

[0048] (3) Finally, refer to GB / T20944.1~2007 "Evaluation of antibacterial properties of textile materials: Agar plate diffusion method" or GB / T20944.2~2007 "Evaluation of antibacterial properties of textile materials: Absorption method" or GB / T20944. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com