Construction method used for tunnel road surface water seepage governance

A construction method and tunnel technology, which is applied in the construction field of tunnel pavement water seepage control, can solve the problems of limited drainage area, reduced vehicle traction, and reduced service life of tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

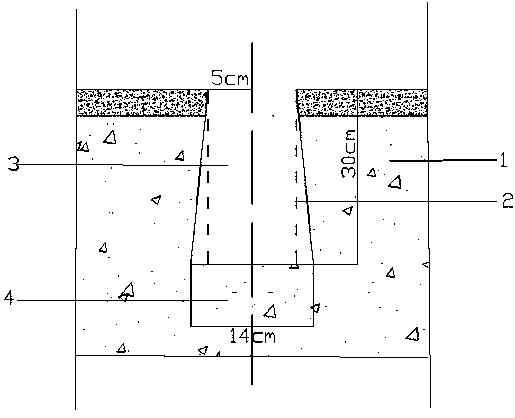

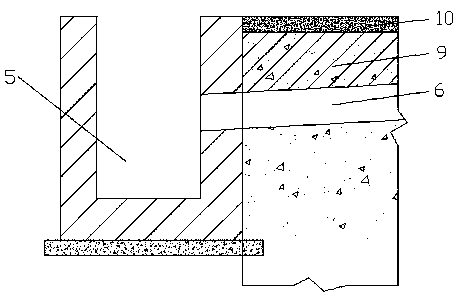

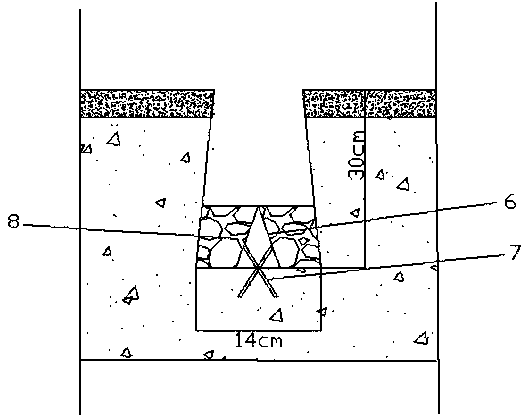

[0025] Such as figure 1 As shown, a construction method for the control of water seepage on the tunnel pavement, the construction method adopts the method of forming holes with angle steel for drainage, finds the water outlet point and the scope of water seepage, and sprays water on the site of water seepage on the original concrete pavement 1 of the tunnel Lay dry PC32.5# cement, observe the infiltration of the road surface, take the central point of the road surface with obvious water leakage or large-scale infiltration range as the water seepage point, and place 5cm on both sides of the water seepage point determined by the original concrete road surface 1 of the tunnel Carry out the cutting of transverse driving lane, form described cutting groove 2, further carry out groove on the basis of described cutting groove 2, form described trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com