Finished product post-cast strip

A technology of post-casting strips and finished products, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of waste of materials and manpower, time-consuming secondary drilling, time-consuming processing of steel bars and steel wire mesh, etc., to speed up advancement and backfilling , Put an end to common quality problems and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

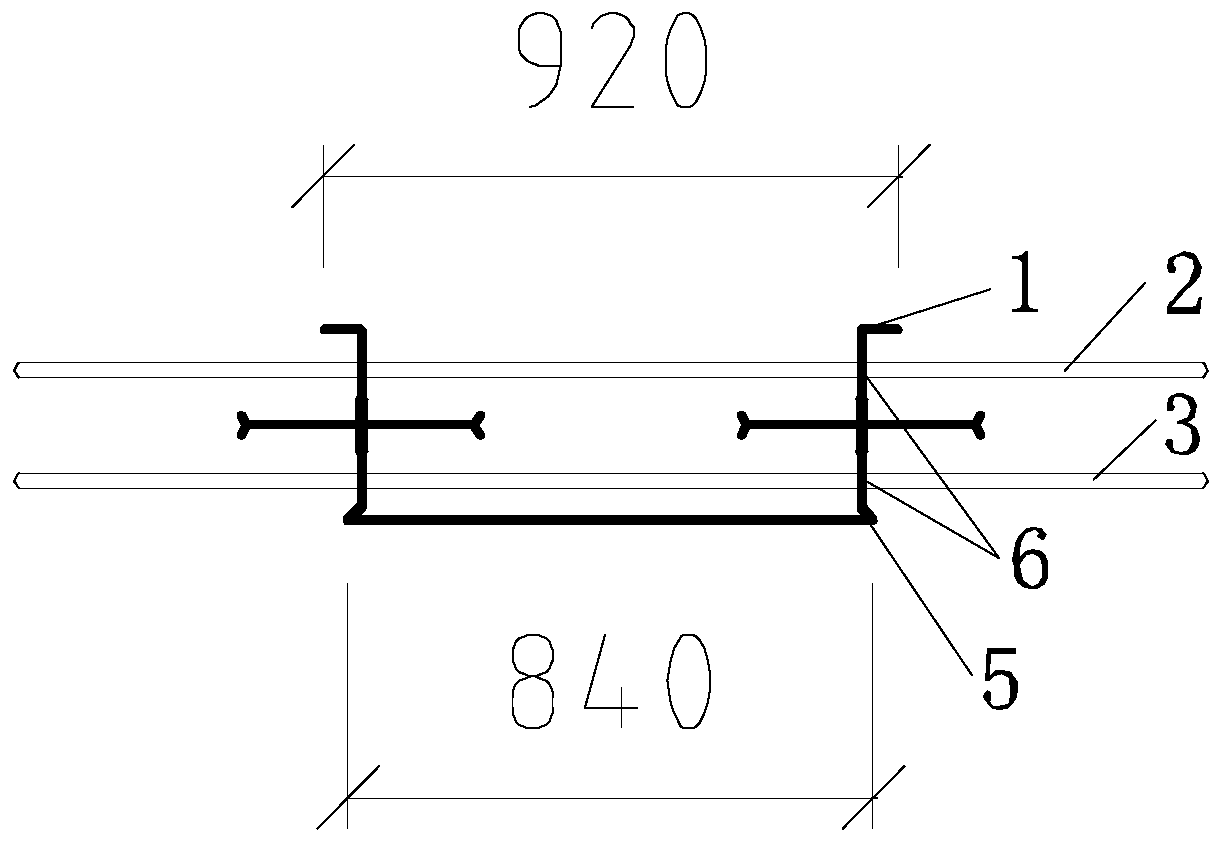

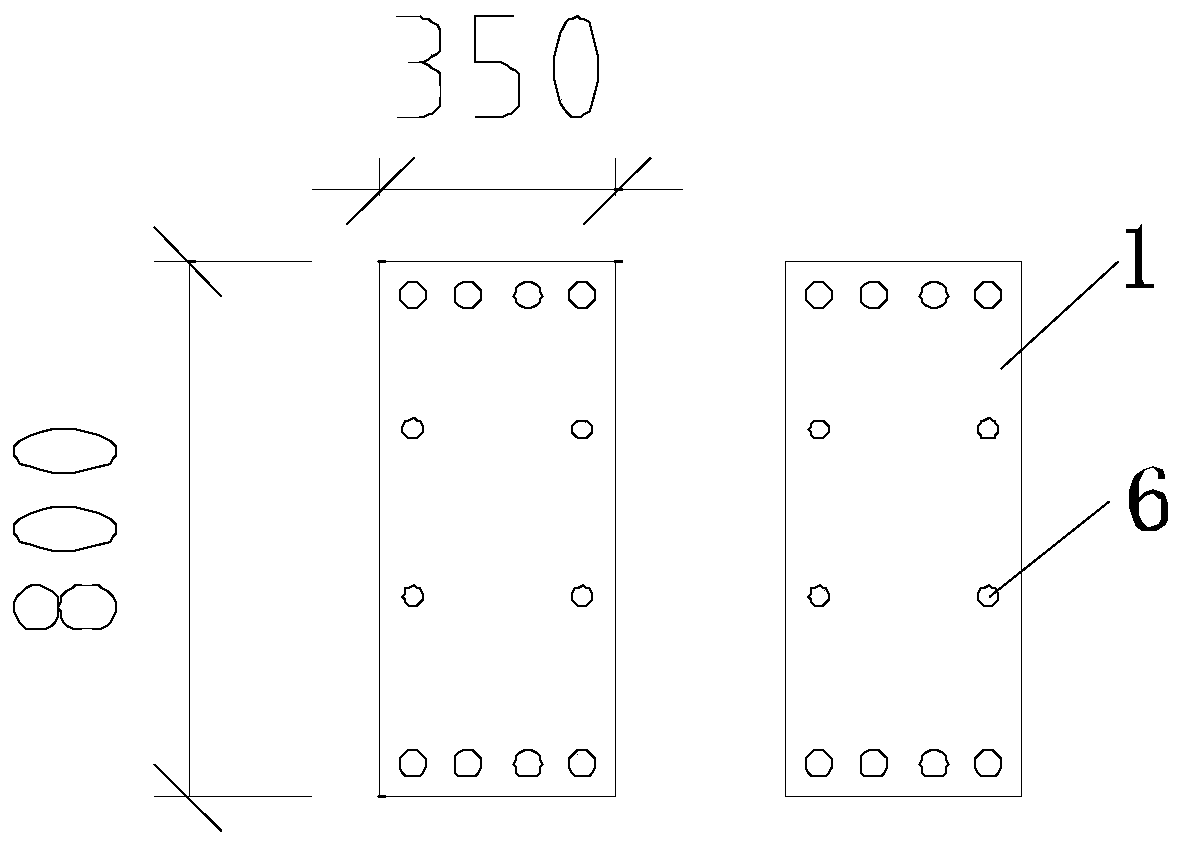

[0064] see Figure 1~3 The post-casting belt of the finished beam includes a semi-closed groove body composed of stainless steel 1 which is fully welded by argon arc welding, steel bars on the floor slab 2, steel bars under the floor slab 3, rubber waterstop 4, concrete shrinkage compensation angle 5 and wear-through Socket 6, wherein the top ends of the semi-closed groove body are respectively provided with outwardly extending ends, and the bottom ends of the semi-closed groove body are respectively provided with concrete shrinkage compensation angles 5, and the height of the semi-closed groove body is the same as that of the floor The plate thickness is equal, and a penetration hole 6 is provided on the semi-closed groove body. After the steel bar 2 on the floor plate and the steel bar 3 under the floor slab are symmetrically inserted on the semi-closed groove body through the penetration hole 6, the rubber stop The hose 4 is blocked on the penetration hole 6;

[0065] The ...

Embodiment 2

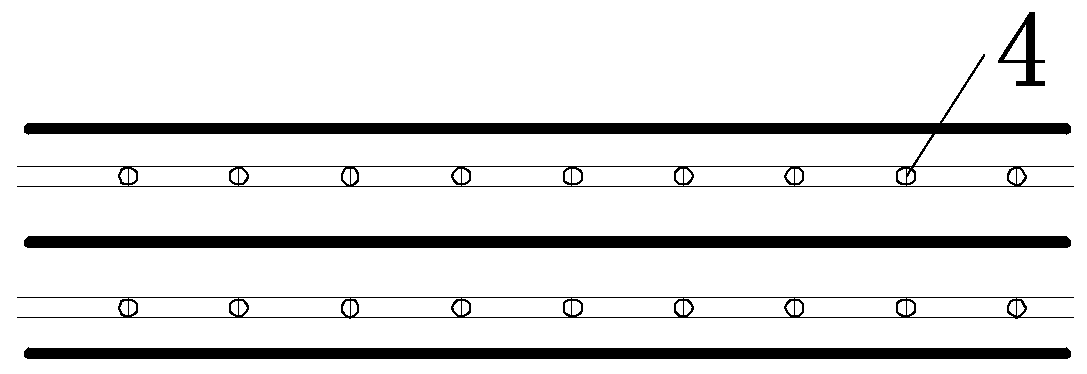

[0077] see Figure 4~6 The post-casting belt of the finished bottom plate includes a semi-closed groove body composed of stainless steel 1 that is fully welded by argon arc welding, steel bars on the floor slab 2, steel bars under the floor slab 3, rubber waterstop 4, concrete shrinkage compensation angle 5 and wear-through Socket 6, wherein the top ends of the semi-closed groove body are respectively provided with outwardly extending ends, and the bottom ends of the semi-closed groove body are respectively provided with concrete shrinkage compensation angles 5, and the height of the semi-closed groove body is in accordance with the design The plate thickness is equal, and a penetration hole 6 is provided on the semi-closed groove body. After the steel bar 2 on the floor plate and the steel bar 3 under the floor slab are symmetrically inserted on the semi-closed groove body through the penetration hole 6, the rubber stop The hose 4 is blocked on the penetration hole 6;

[007...

Embodiment 3

[0088] see Figure 7-8The post-casting belt of the finished exterior wall includes a semi-closed groove body composed of stainless steel 1 that is fully welded by argon arc welding, rubber waterstop 4, concrete shrinkage compensation angle 5, penetration hole 6, steel bar 7 on the shear wall and The steel bars 8 under the shear wall, wherein the top ends of the semi-closed groove body are respectively provided with outwardly extending ends, the bottom ends of the semi-closed groove body are respectively provided with concrete shrinkage compensation angles 5, and the semi-closed groove body The height is equal to the thickness of the shear wall, and a penetration hole 6 is provided on the semi-closed groove body, and the steel bar 7 on the shear wall and the steel bar 8 below the shear wall are symmetrically inserted in the semi-closed groove body through the penetration hole 6 After putting it on, seal the rubber waterstop 4 on the penetration hole 6;

[0089] The penetration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com