Anti-corrosion and heat-insulation processing method for petroleum pipeline

A thermal insulation treatment, oil pipeline technology, applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, thermal insulation, etc., can solve the problems of unclean treatment of impurities such as welding slag, peeling off of the anticorrosion layer, and unevenness, so as to reduce manual operation. Convenience, prevent rust damage, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

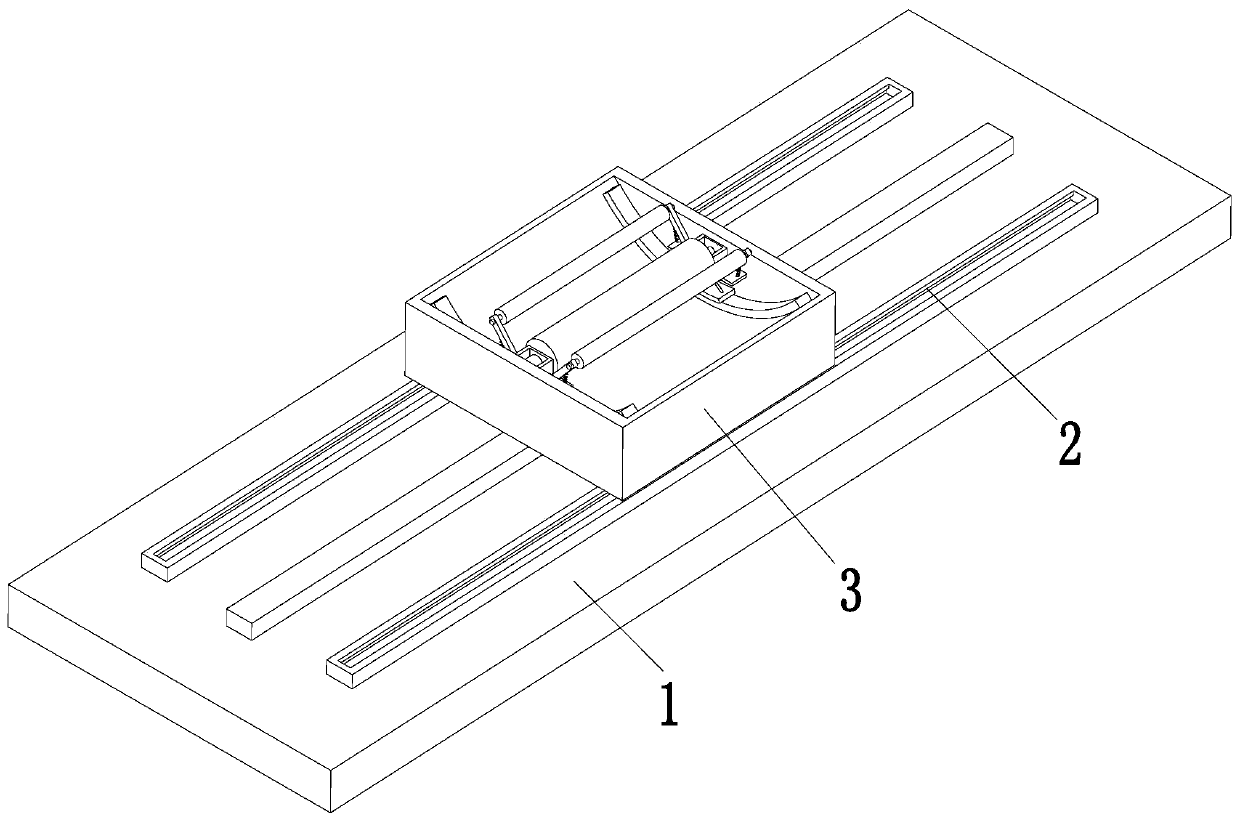

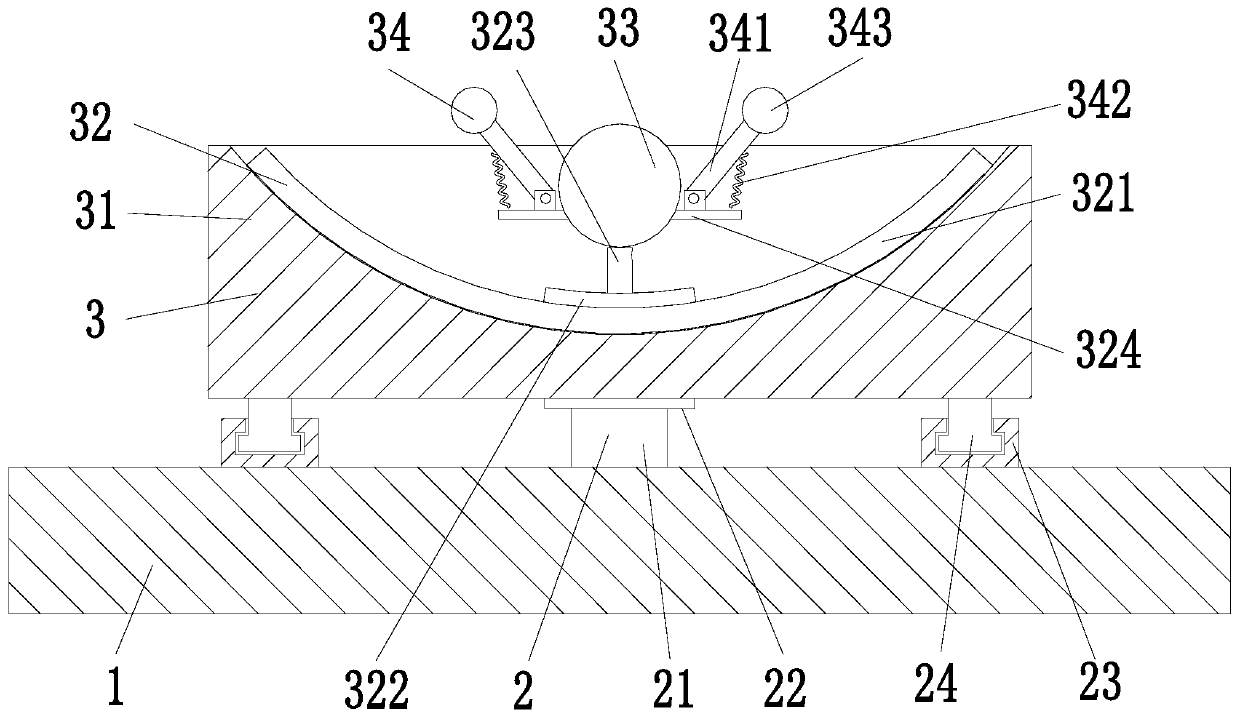

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

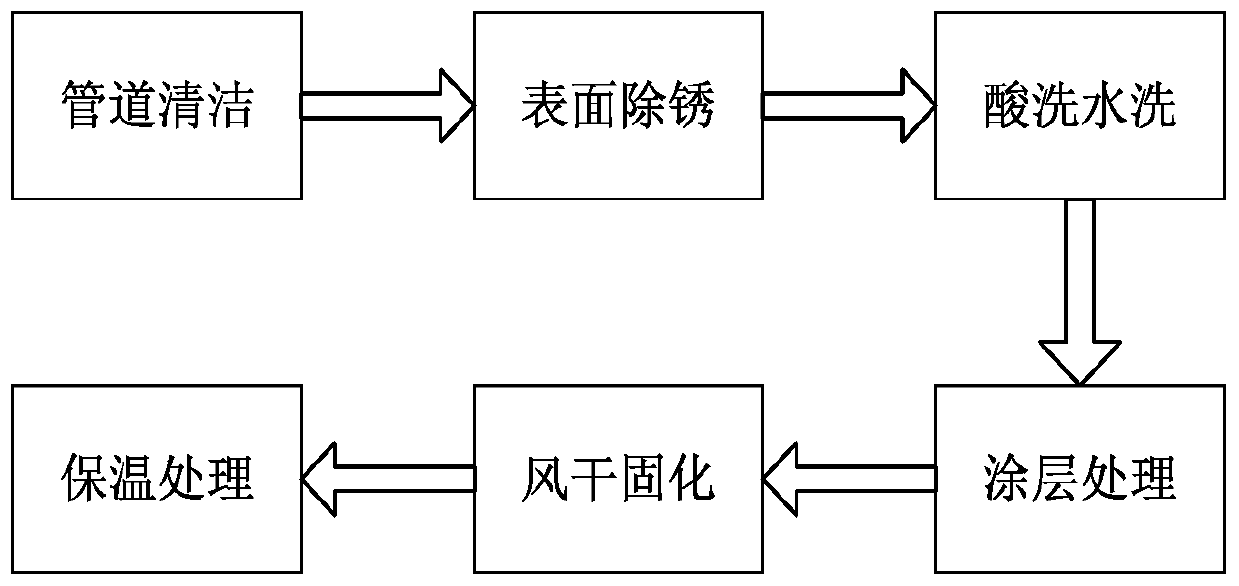

[0036] Such as Figure 1 to Figure 6 Shown, a kind of petroleum pipeline anticorrosion heat preservation treatment method, comprises the following steps:

[0037] S1. Pipeline cleaning: Use solvents, emulsions, etc. to clean the outer surface of the oil pipeline to remove impurities such as grease, dust, lubricants, etc. on the surface of the pipeline;

[0038] S2. Surface derusting: use tools such as wire brushes to polish the cleaned pipeline in step S1 to remove loose or raised oxide skin, rust, welding slag and other residues on the surface of the pipeline;

[0039] S3. Pickling and water washing: further process the outer surface of the pipeline by pickling to improve the cleanliness and roughness of the pipeline surface, and then remove the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com