Apparatus and method for continuously drying bulk goods, in particular wood chips and/or wood fibers comprising hot gas cyclone

A wood fiber and hot gas technology, applied in the field of wood fiber and/or wood chips, can solve the problems of adverse effects on the effectiveness of heat exchangers, deterioration of the service life of heat exchangers, and expensive cleaning of heat exchangers, so as to improve the total heat and energy. Effects of mass productivity, suppression of formation of nitrogen oxides, and ease of operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

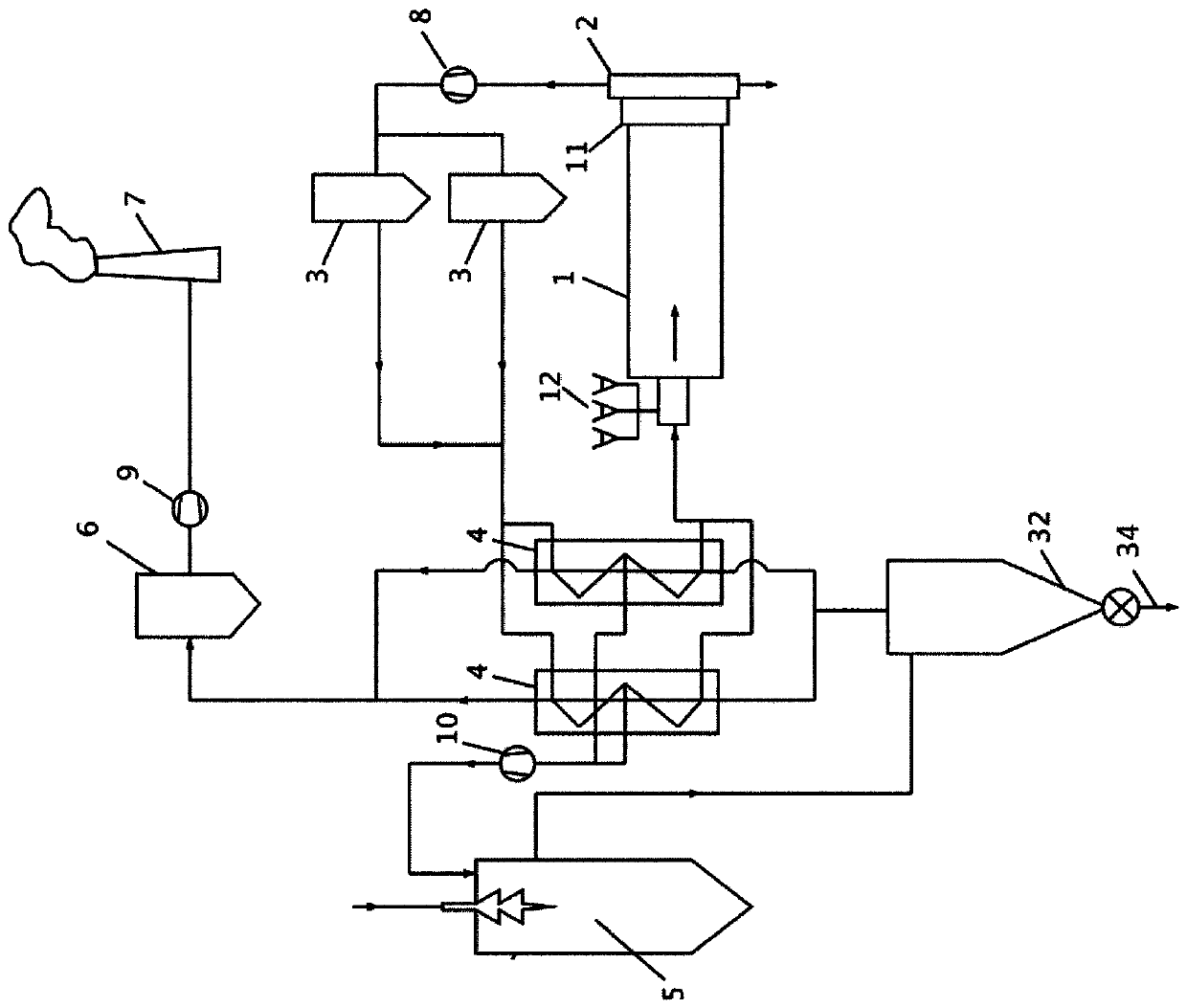

[0086] figure 1A first example of a device of the invention implementing the method of the invention is shown. The plant comprises a tumble dryer 1, a discharge housing 2, two cleaning devices 3 operating in parallel, two heat exchangers 4 operating in parallel, a hot gas generator for combustion of the fuel / combustion air mixture (in figure 1 In the case of a multi-fuel burner 5) with a combustion chamber, a filter 6 and a chimney 7. Drying steam produced by drying eg wood chips in the drying tumble dryer 1 is introduced into the drying circuit. The drying steam fan 8 is arranged between the tumble dryer 1 and the cleaning device 3, the burner exhaust fan 9 is arranged between the filter 6 and the chimney 7, and between the heat exchanger 4 and the combustion chamber 5 a possible Regulated partial steam fan 10. The dryer 1 can be provided with a deceleration zone 11 and a metering device 12 . The inlet of the fuel into the burner 5 is not shown in detail.

[0087] The tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com