Evaporation drying system and evaporation tower thereof

An evaporation tower, drying technology, applied in the direction of evaporation, spray evaporation, evaporator accessories, etc., can solve the problems of poor drying quality and low drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

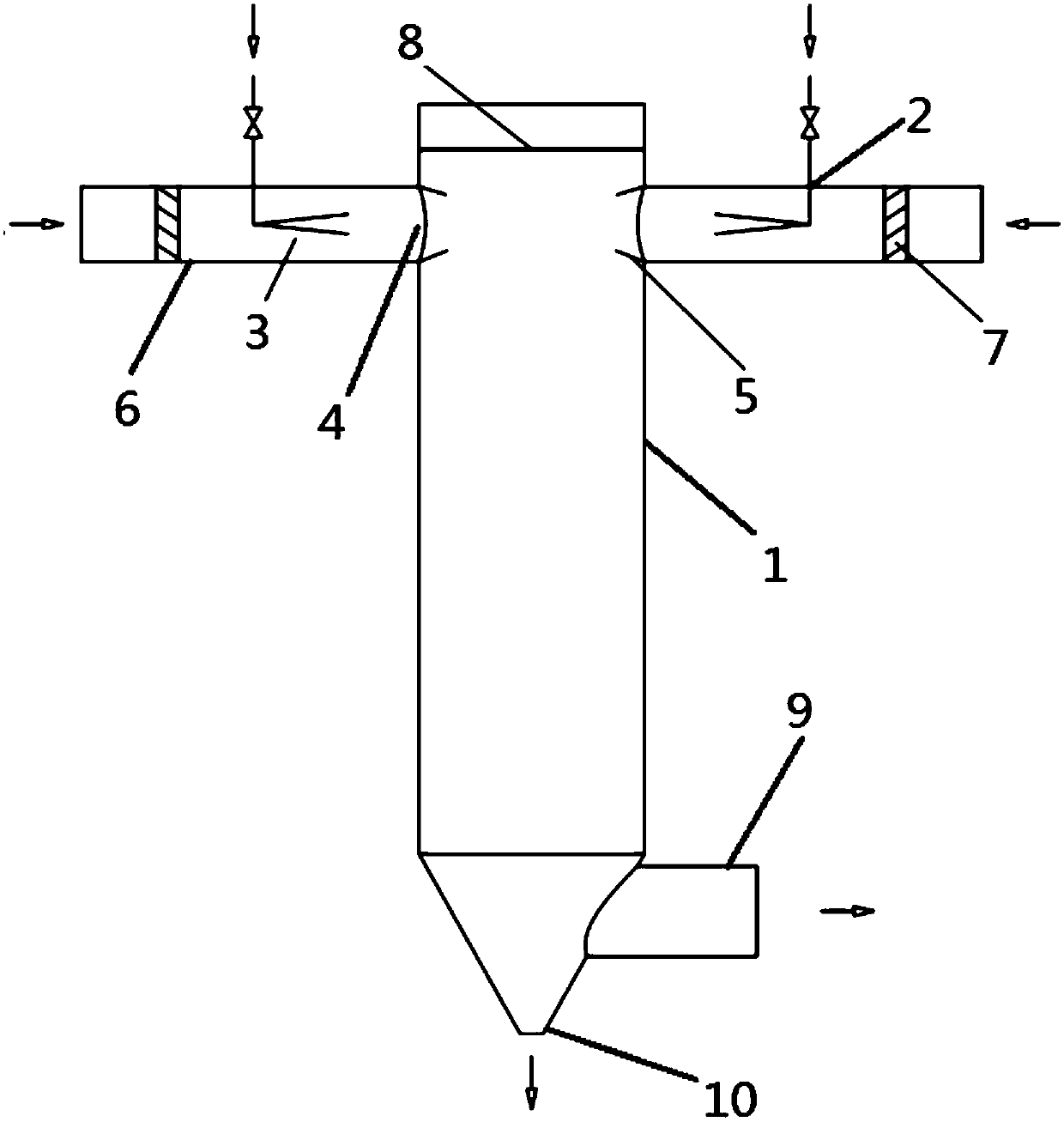

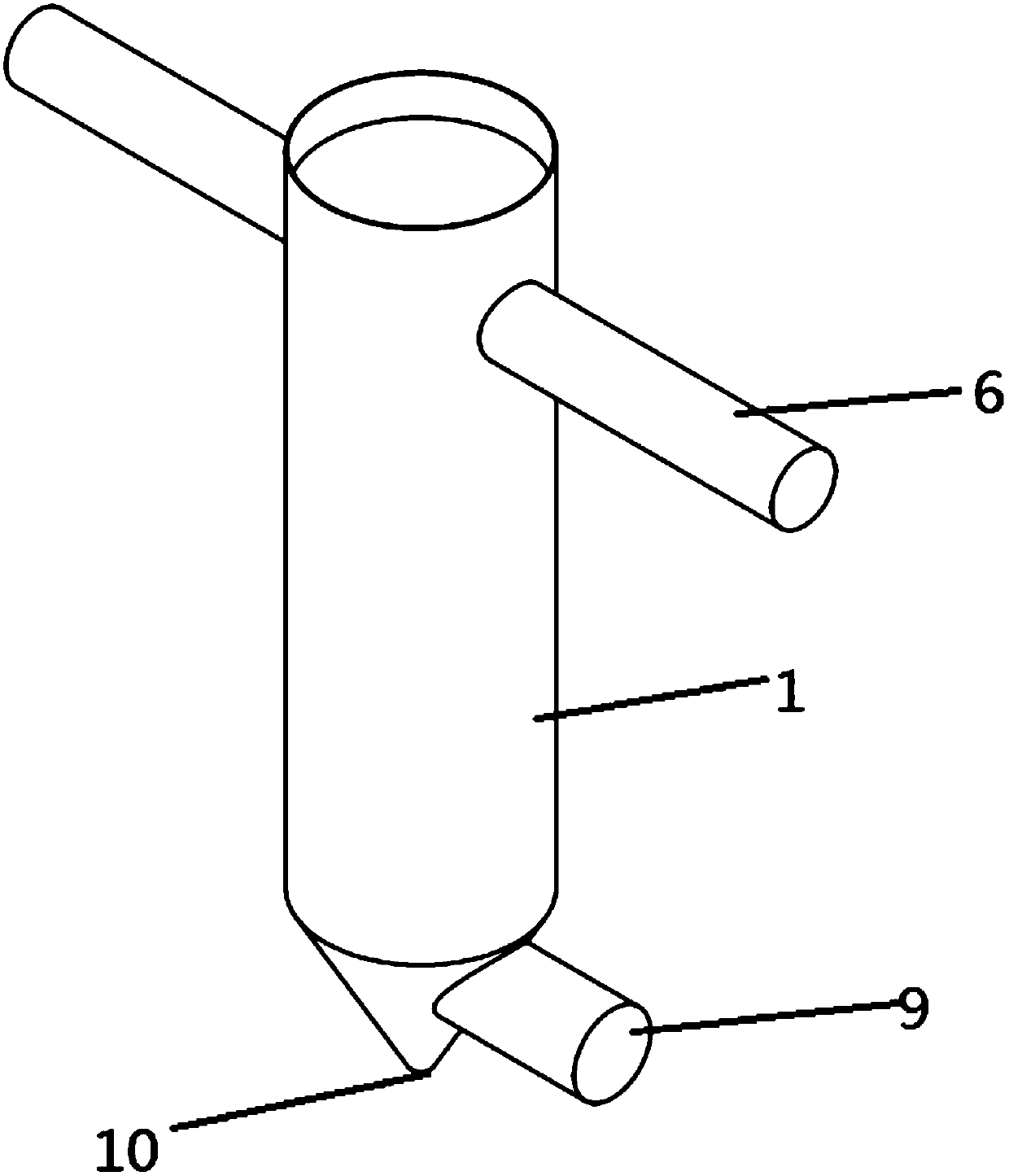

[0029] Such as figure 1 with figure 2 As shown, the evaporation tower provided by this embodiment includes: a tower body 1 having a cavity; a pair of atomizers, arranged on the tower body 1, having a mist outlet 2, suitable for generating atomization Material to be dried; a pair of air jets 4, which are relatively coaxially arranged on the tower body 1, suitable for injecting opposing high-temperature dry gas into the cavity, between the pair of air jets 4 A gas opposing zone is formed, and the mist exit path of the mist outlet 2 passes through the gas opposing zone, so that the high-temperature dry gas is mixed with the atomized material to be dried.

[0030] Since the pair of air jets 4 are arranged relatively coaxially, the two high-temperature dry gases entering the evaporation tower oppose each other to form a gas counteracting area, and the material to be dried atomized by the atomizer is atomized into fine droplets. On the one hand, In the hedging zone, the gas turbulenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com