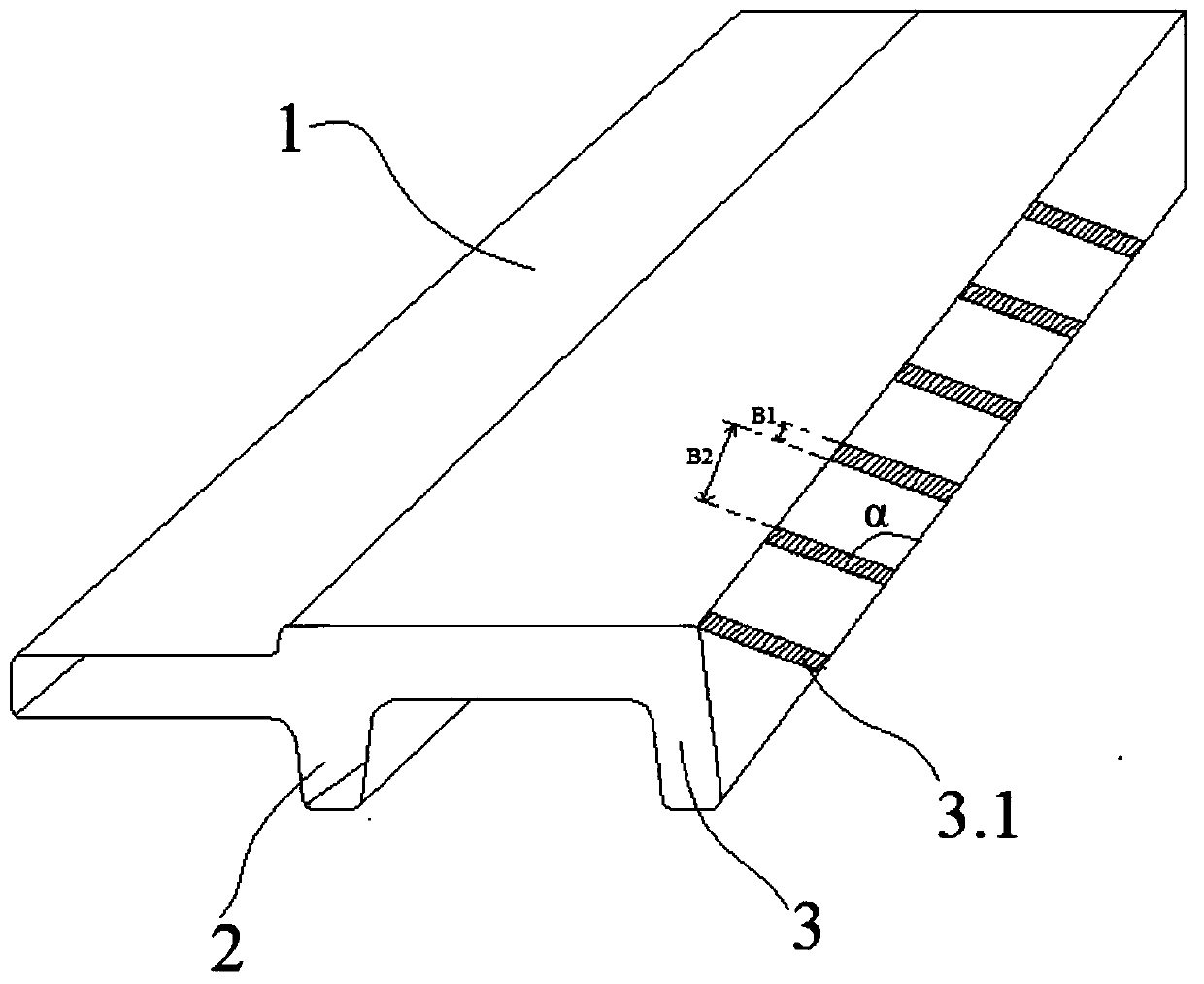

F type rail used for reducing frictional losses of magnetic-levitation train and preparing method thereof

A friction loss, maglev train technology, applied in tracks, buildings, roads, etc., can solve the problems of increasing the maintenance cost of maglev tracks, thinning of the outer legs of the F-rail, hidden dangers of vehicle safety, etc., so as to improve operation safety and reduce maintenance costs. , The effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention discloses a method for preparing the F-shaped rail for reducing friction loss of a maglev train, which includes the following processes:

[0036] Hot metal desulfurization: using magnesium powder desulfurization process;

[0037] Converter smelting: adopt top and bottom combined blowing process;

[0038] LF refining outside the furnace: the slag basicity is controlled in the range of 1.6 to 2.0;

[0039] Vacuum treatment: the vacuum treatment time is not less than 20min;

[0040] Continuous casting: During the continuous casting process, the temperature of the tundish is controlled at the liquidus 18~24℃, and the pulling speed is 0.6~1.0m / min. The continuous casting process should be carried out under the protection of the whole process to prevent contact with air. The billet should be slowly cooled;

[0041] Billet heating: use walking beam heating furnace to heat the billet, and conduct heat preservation treatment, the heating temperature is 1200~1260℃, and the he...

Embodiment 1

[0048] This embodiment discloses a method for preparing the above-mentioned F-shaped rail for reducing the friction loss of a maglev train, wherein each chemical component is calculated by mass percentage, including: C: 0.03%, Si: 0.25%, Mn: 1.5% , P: 0.002%, S: 0.002%, Cr: 0.10%, Ni: 0.10%, Nb: 0.02%, B: 0.002%; the balance is Fe and unavoidable impurities.

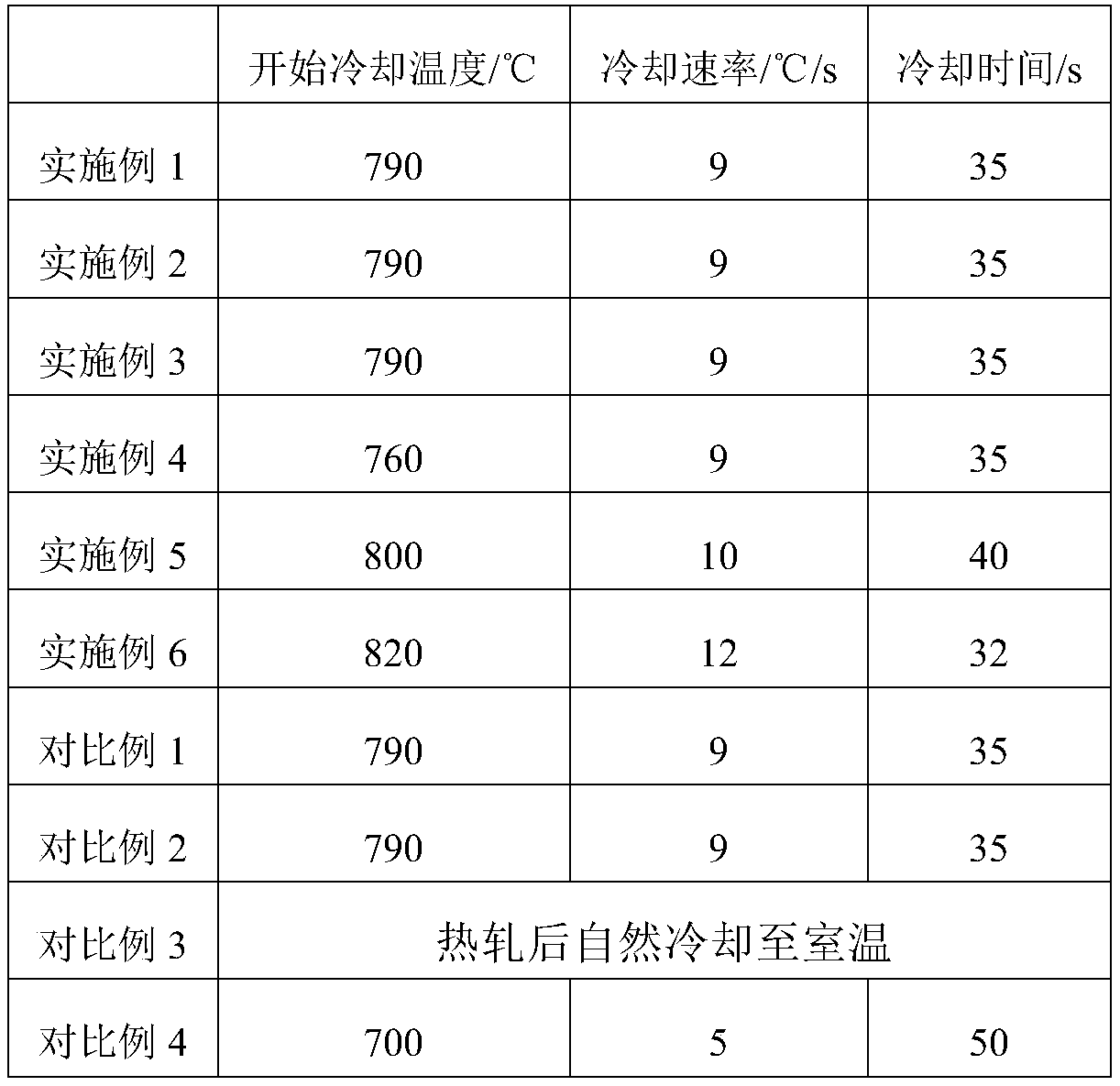

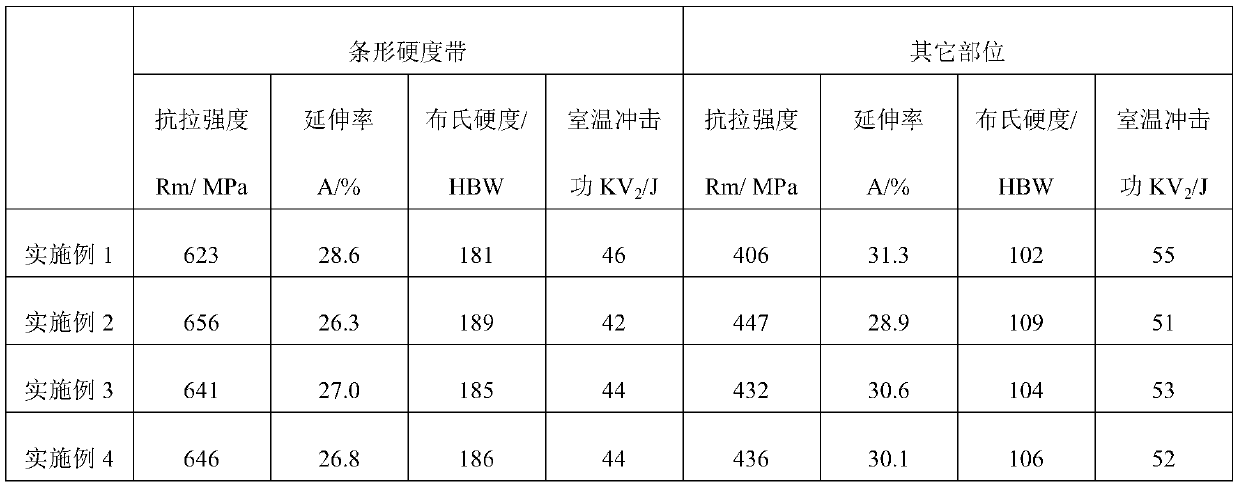

[0049] The specific accelerated cooling and heat treatment process for the F-shaped steel outer leg is shown in Table 1; the obtained length is 12.5 meters and the specification is F379×101mm.

Embodiment 2

[0051] This embodiment discloses a method for preparing the above-mentioned F-shaped rail for reducing the friction loss of a maglev train, wherein each chemical component is calculated by mass percentage, including: C: 0.09%, Si: 0.40%, and Mn: 2.0% , P: 0.002%, S: 0.002%, Cr: 0.30%, Ni: 0.25%, Nb: 0.06%, B: 0.006%; the balance is Fe and unavoidable impurities.

[0052] The specific accelerated cooling heat treatment process for the F-shaped steel outer leg is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com