Tool for preheating cylinder body circular seam before welding and removing hydrogen after welding and using method of tool

A technology of girth seam welding and cylinder body, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of affecting the quality of welding seam, slow heating rate, uneven heating, etc., and achieve wide practical range, uniform heating, combustion full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

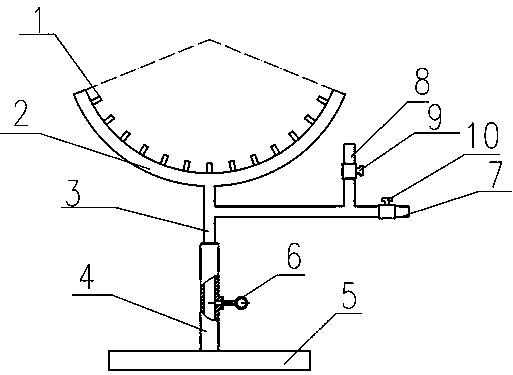

[0012] The present invention is a tool for preheating the girth seam of a container cylinder before welding and eliminating hydrogen after welding, such as figure 1 As shown, its structure includes burner 1, concave arc heating tube 2, oxygen-enriched gas tube 3, support tube 4, support 5, fixing screw 6, gas tube 7, oxygen-enriched air tube 8, air shut-off valve 9, Gas cut-off valve 10; the support pipe 4 is welded at the center of the support 5, and the lower end of the oxygen-enriched gas pipe 3 is assembled to the inside of the support pipe 4, fixed by a fixing screw 6, and the height of the oxygen-enriched gas pipe can be adjusted; the air cut-off valve 9 Control the oxygen-enriched air pipe 8, and the gas stop valve 10 controls the gas pipe 7; The inner cavity at the lowest point is connected, and the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com