Elongated precise thin-wall aluminum alloy pipe inner hole polishing and grinding tool and method

A technology for aluminum alloys and pipes, which is applied in the field of inner hole polishing tools for slender precision thin-walled aluminum alloy pipes, can solve problems such as high ellipticity of pipes, low product pass rate, and failure of polishing effects to meet technical requirements, etc., to achieve Stable polishing quality and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

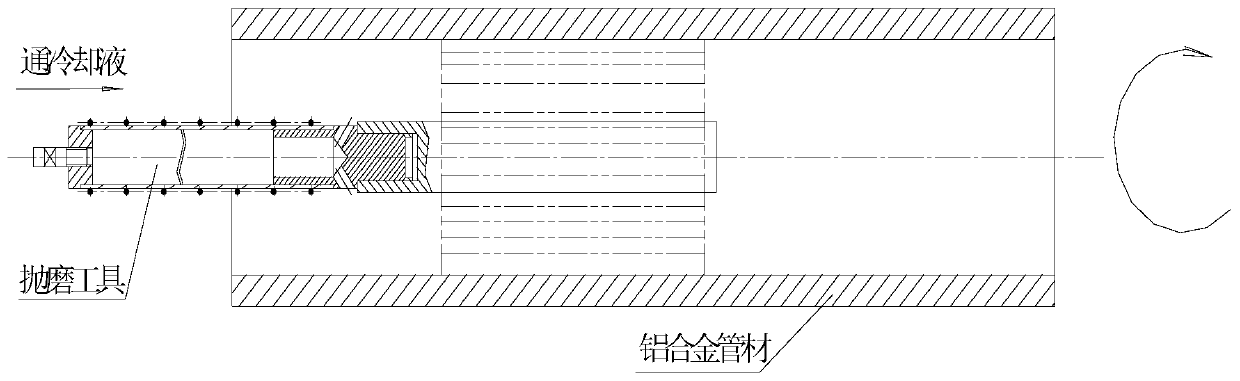

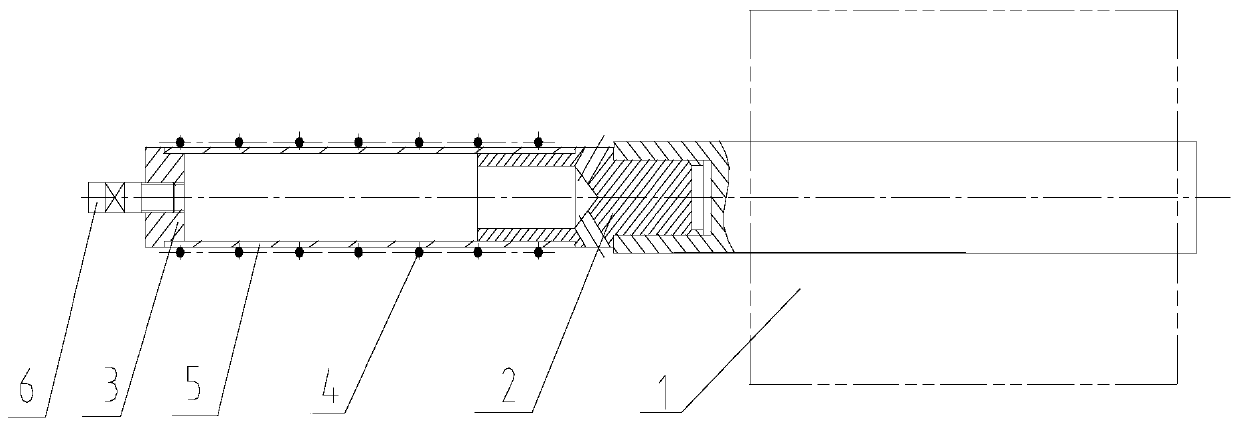

[0020] The present invention is further described below in conjunction with accompanying drawing:

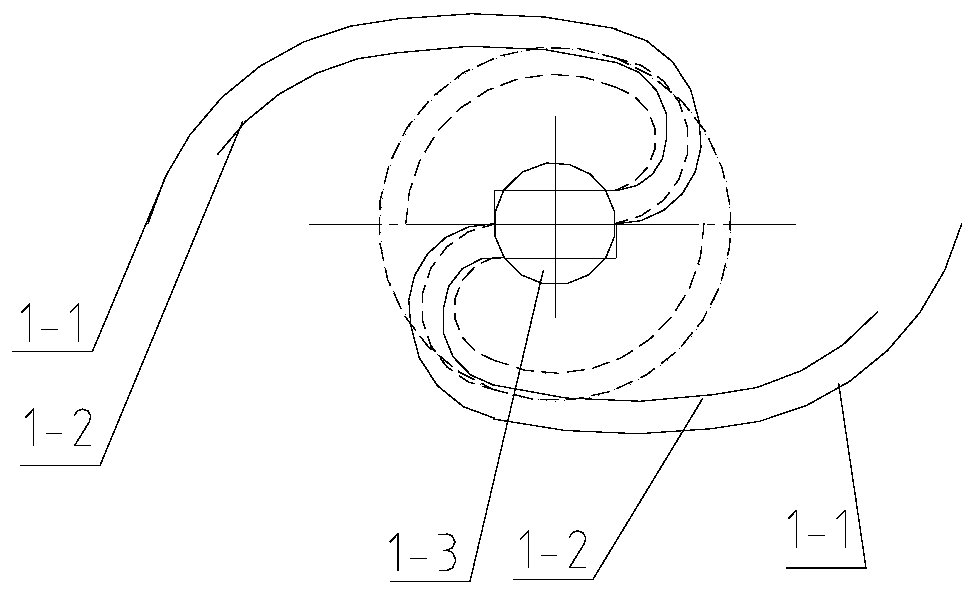

[0021] Such as figure 2 As shown, a slender precision thin-walled aluminum alloy pipe inner hole polishing tool includes a grinding head assembly 1, a connecting head 2, a sealing head 3, a protective rubber ring 4, a grinding rod 5, and a liquid valve 6; the connecting head 2 It is a columnar stepped structure, the small diameter end is fixedly connected to the grinding head assembly 1, and the large diameter end of the connecting head 2 is provided with a water hole, which runs through the water hole and has 2 water outlets symmetrically, and the grinding rod 5 is set on the connecting head 2 One end with a large diameter and the other end of the grinding rod 5 are set on the sealing head 3, and they are fixedly connected by glue bonding to ensure the connection strength requirements and reliable connection; the liquid passage valve 6 is installed in the threaded hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com