Method for conducting pre-treatment on waste incineration bottom ash aggregate by means of cement paste

A technology for waste incineration and cement slurry cleaning, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of high operating conditions and equipment requirements, high time cost, and high cost, and achieve good bonding effect , low cost, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

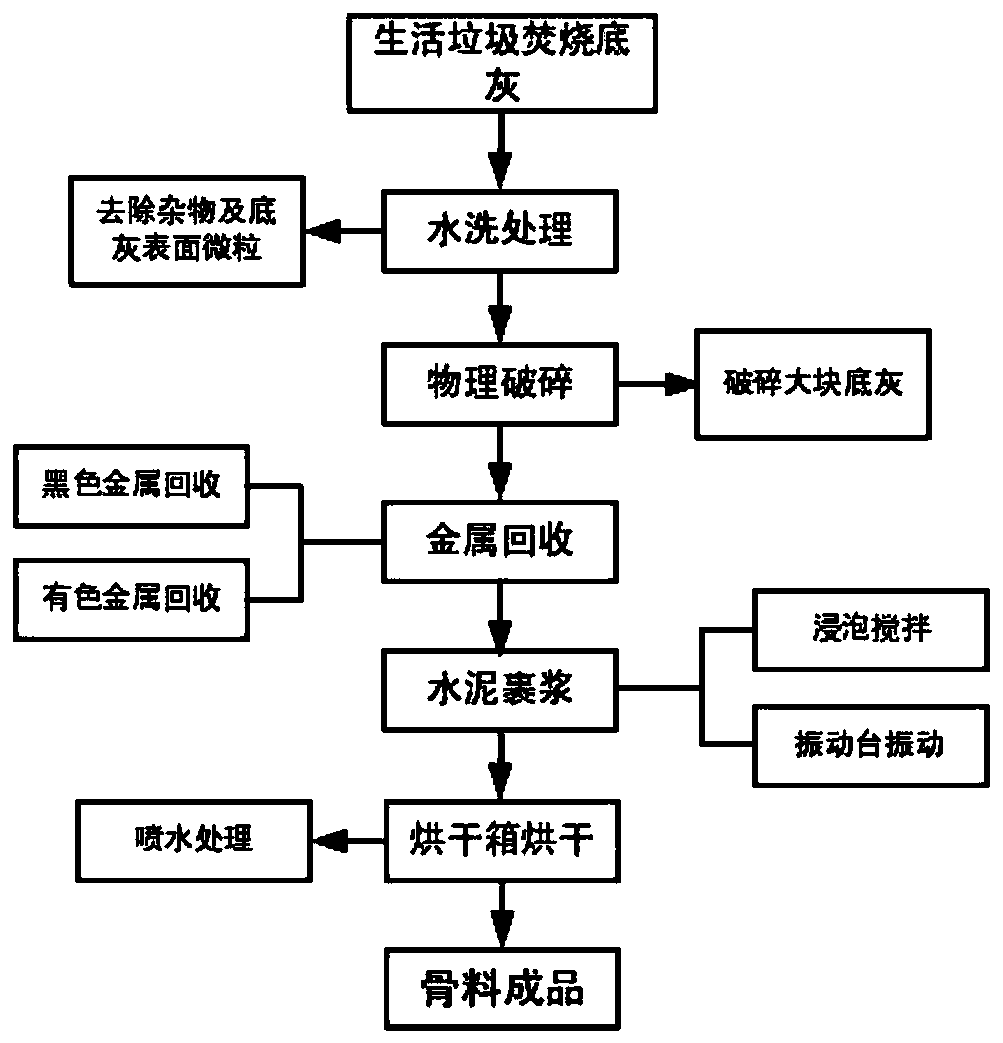

[0020] Implementation case: a method for pretreating waste incineration bottom ash aggregate with cement slurry, the steps are as follows:

[0021] Step 1: First, wash the bottom ash of garbage incineration with water to remove unburned wood chips, plastics and other debris, and at the same time remove the tiny particles bonded to the surface of the bottom ash;

[0022] Step 2: Use a crusher to crush the bottom ash of bulk waste incineration;

[0023] Step 3: Manual or machine selection of ferrous metals and non-ferrous metals;

[0024] Step 4: After the crushed waste incineration bottom ash is classified into aggregate by a sieving machine, three kinds of particle sizes of waste incineration bottom ash aggregate (5-10mm, 10-15mm and 15-20mm) are obtained;

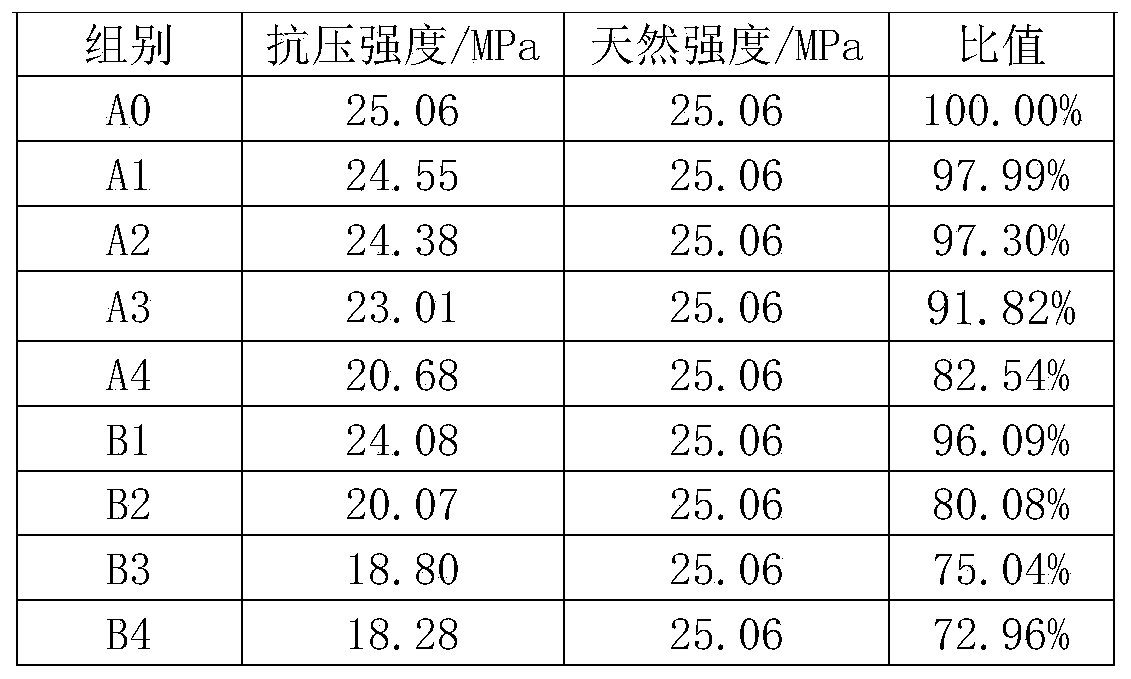

[0025] Step 5: The bottom ash aggregates treated with water-cement ratios of 0.4, 0.5 and 0.6 were subjected to crushing index tests. The test results showed that the cement paste with a water-cement ratio of 0.4 had the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com