Preparation method of phosphorus-copper alloy

A phosphor-copper alloy and yellow phosphorus technology is applied in the preparation field of phosphor-copper alloy, which can solve the problems of large phosphorus loss, poor product quality, poor reaction effect, etc., and achieve the effects of increasing the content and improving the absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of phosphorous copper alloy, comprising the steps,

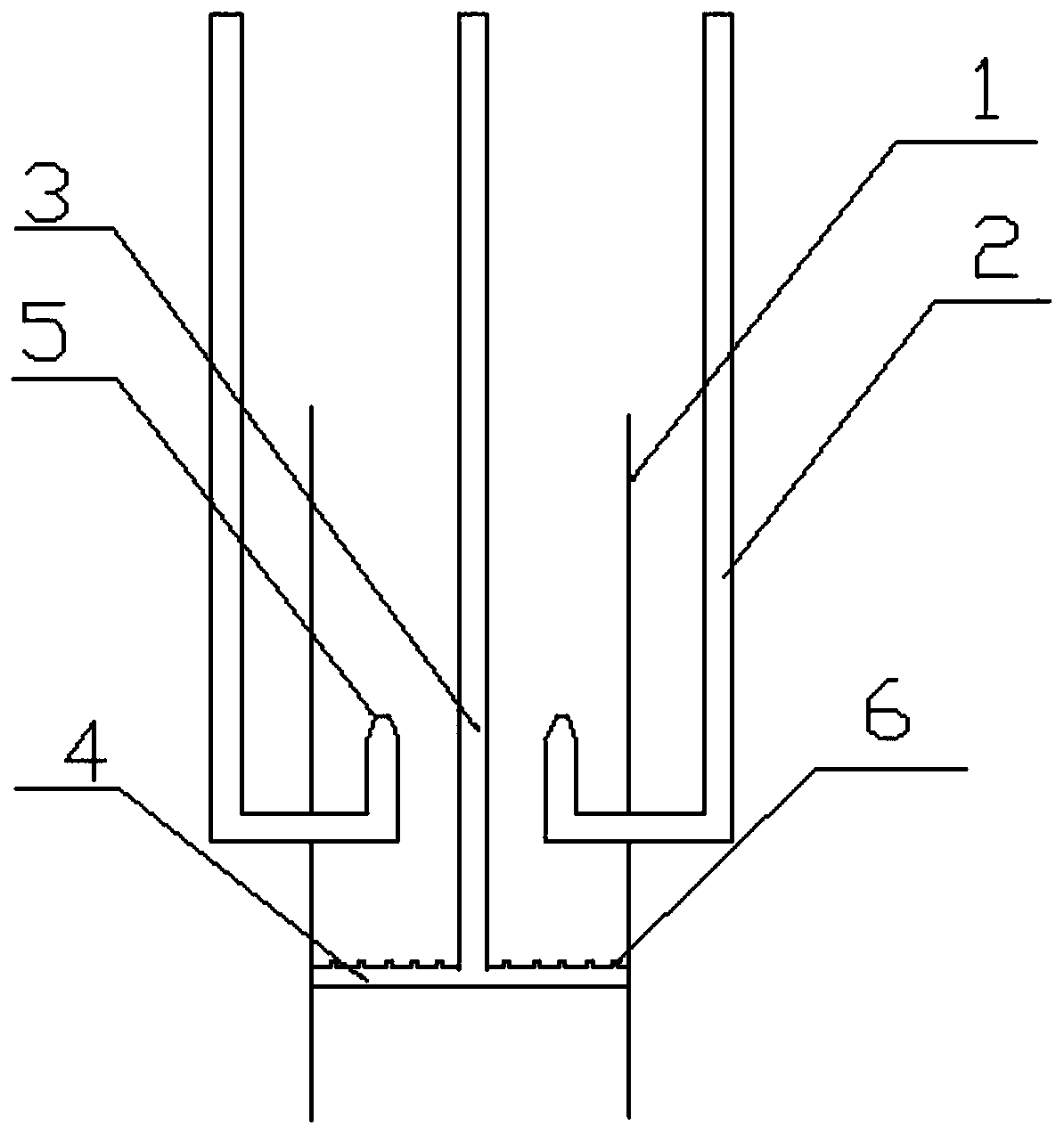

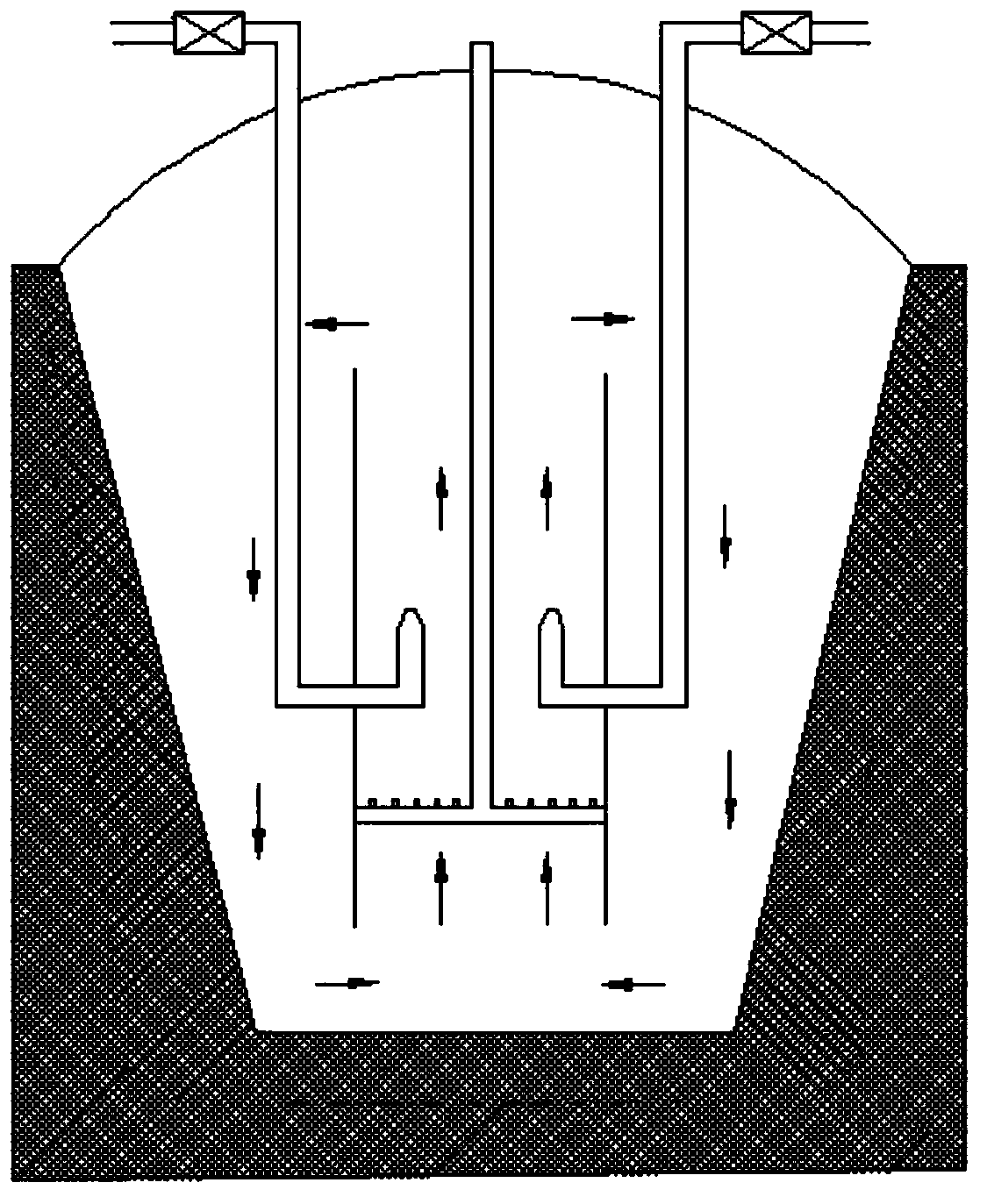

[0019] 1) Put the electrolytic copper into the smelting furnace, vertically insert the phosphorus adding device into the smelting furnace, the upper and lower ends of the cylinder are connected with the smelting furnace, and the upper part of the main phosphorus adding pipeline and the inert gas pipeline extends out of the smelting furnace roof. Outside the cover and sealingly connected with the top cover; the main phosphorus adding pipeline extending out of the top cover is connected with the phosphorus melting device (not shown in the accompanying drawings) through a pressure pump, and the inert gas pipeline extending out of the top cover is connected with the inert gas storage through a circulating pump. Tanks (not shown in the accompanying drawings) are connected;

[0020] 2) Open the smelting furnace, heat and melt the electrolytic copper, raise the temperature to 1160°C and stop heating, con...

Embodiment 2

[0025] A preparation method of phosphorous copper alloy, comprising the steps,

[0026] 1) Put the electrolytic copper into the smelting furnace, vertically insert the phosphorus adding device into the smelting furnace, the upper and lower ends of the cylinder are connected with the smelting furnace, and the upper part of the main phosphorus adding pipeline and the inert gas pipeline extends out of the smelting furnace roof. Outside the cover and sealingly connected with the top cover; the main phosphorus adding pipeline extending out of the top cover is connected with the phosphorus melting device (not shown in the accompanying drawings) through a pressure pump, and the inert gas pipeline extending out of the top cover is connected with the inert gas storage through a circulating pump. Tanks (not shown in the accompanying drawings) are connected;

[0027] 2) Open the smelting furnace, heat and melt the electrolytic copper, raise the temperature to 1170°C and stop heating, con...

Embodiment 3

[0032] A preparation method of phosphorous copper alloy, comprising the steps,

[0033] 1) Put the electrolytic copper into the smelting furnace, vertically insert the phosphorus adding device into the smelting furnace, the upper and lower ends of the cylinder are connected with the smelting furnace, and the upper part of the main phosphorus adding pipeline and the inert gas pipeline extends out of the smelting furnace roof. Outside the cover and sealingly connected with the top cover; the main phosphorus adding pipeline extending out of the top cover is connected with the phosphorus melting device (not shown in the accompanying drawings) through a pressure pump, and the inert gas pipeline extending out of the top cover is connected with the inert gas storage through a circulating pump. Tanks (not shown in the accompanying drawings) are connected;

[0034] 2) Open the smelting furnace, heat and melt the electrolytic copper, raise the temperature to 1170°C and stop heating, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com