Steam turbine oil product online monitoring and analyzing system and method for nuclear power

An analysis system and steam turbine technology, applied in the field of nuclear power plants, can solve problems such as failure mode management in place, unsatisfactory application and promotion, and difficulty in on-site implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

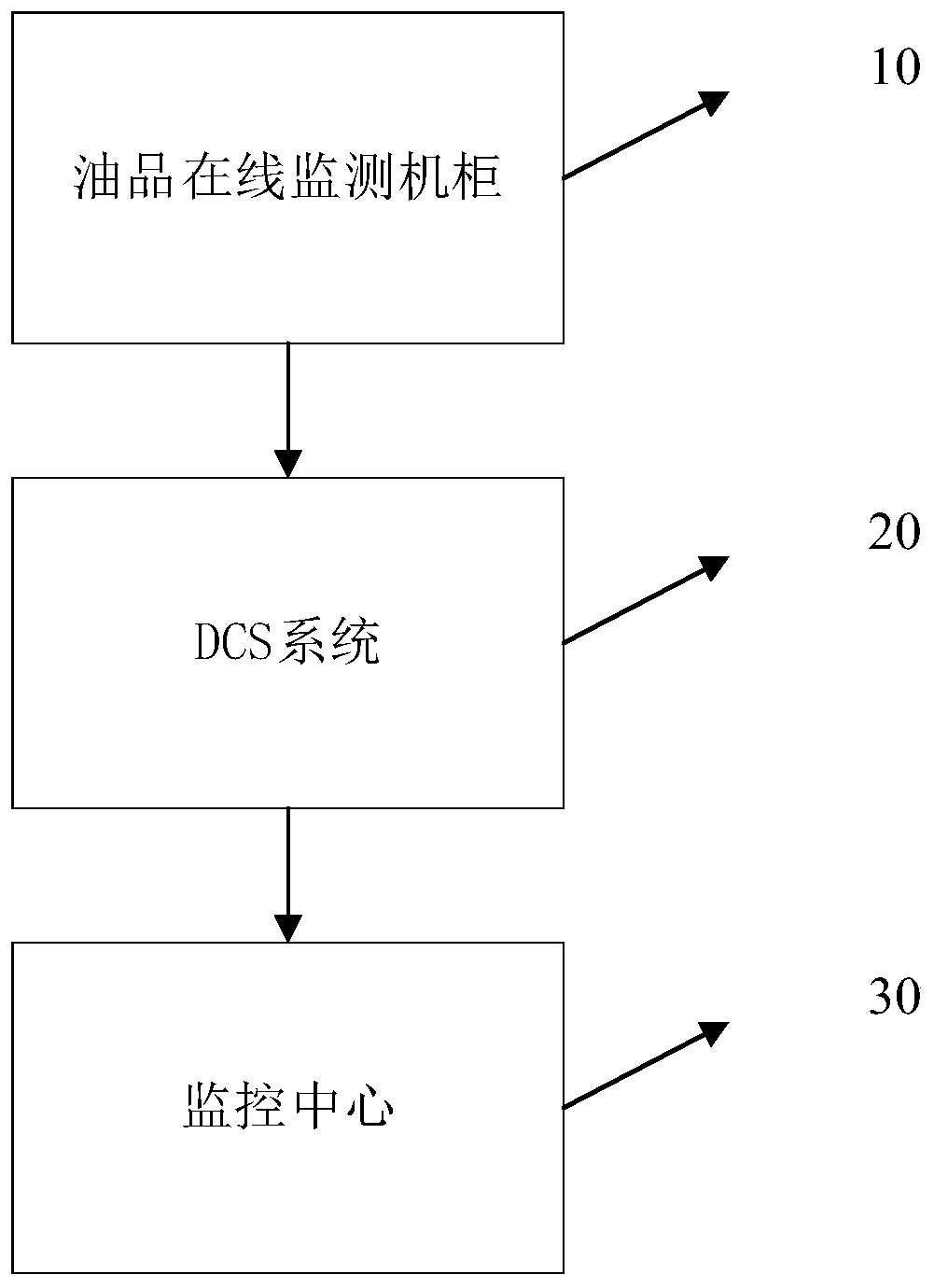

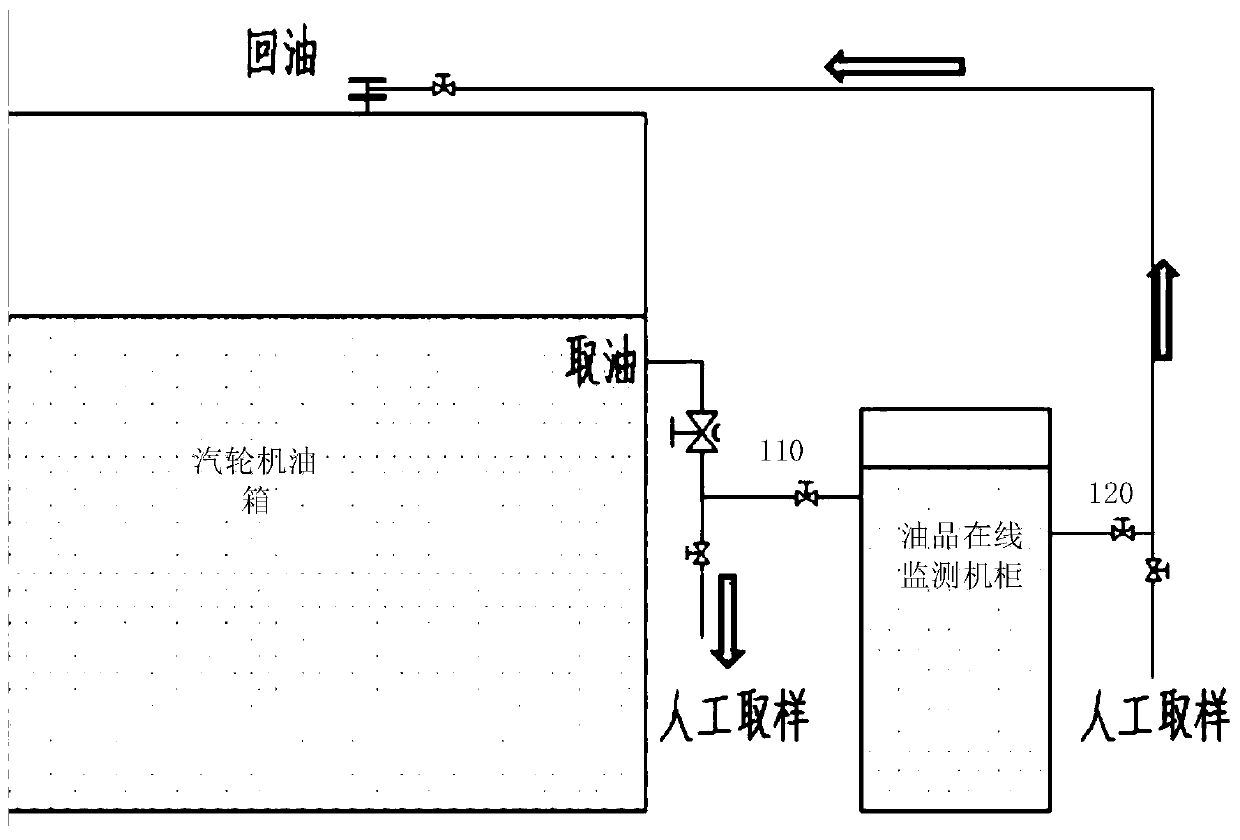

[0025] figure 1 It is a schematic diagram of an on-line monitoring and analysis system for steam turbine oil used in nuclear power provided by an embodiment of the present invention. Such as figure 1 As shown, the steam turbine oil online monitoring and analysis system for nuclear power plants of the present invention includes an oil online monitoring cabinet 10 , a DCS system 20 and a monitoring center 30 . Oil product online monitoring cabinet 10 collects the oil product of the steam turbine oil tank, and after analysis, the generated online monitoring data of steam turbine lubricating oil oil product is transmitted to the DCS system through the signal cable through the 4-20mA analog signal, and uploaded to the monitoring center through the DCS system ; Users can query data in the monitoring center, and realize early warning and fault diagnosis of steam turbines through the monitoring center.

[0026] Specifically, in an embodiment of the present invention, the oil online ...

Embodiment 2

[0032] Figure 4 It is a flow chart of an online monitoring and analysis method for steam turbine oil used in nuclear power provided by an embodiment of the present invention. Such as Figure 4 Shown, nuclear power steam turbine oil online monitoring analysis method of the present invention comprises the following steps:

[0033] Step S410: The oil online monitoring cabinet is used to analyze and test the lubricating oil from the steam turbine oil tank to generate online monitoring data of the steam turbine lubricating oil;

[0034] Specifically, in an embodiment of the present invention, the on-line monitoring data of steam turbine lubricating oil includes particle size, water content, kinematic viscosity, dielectric constant, temperature, density

[0035] Step S420: Send the online monitoring data of the steam turbine lubricating oil to the monitoring center via the DCS system;

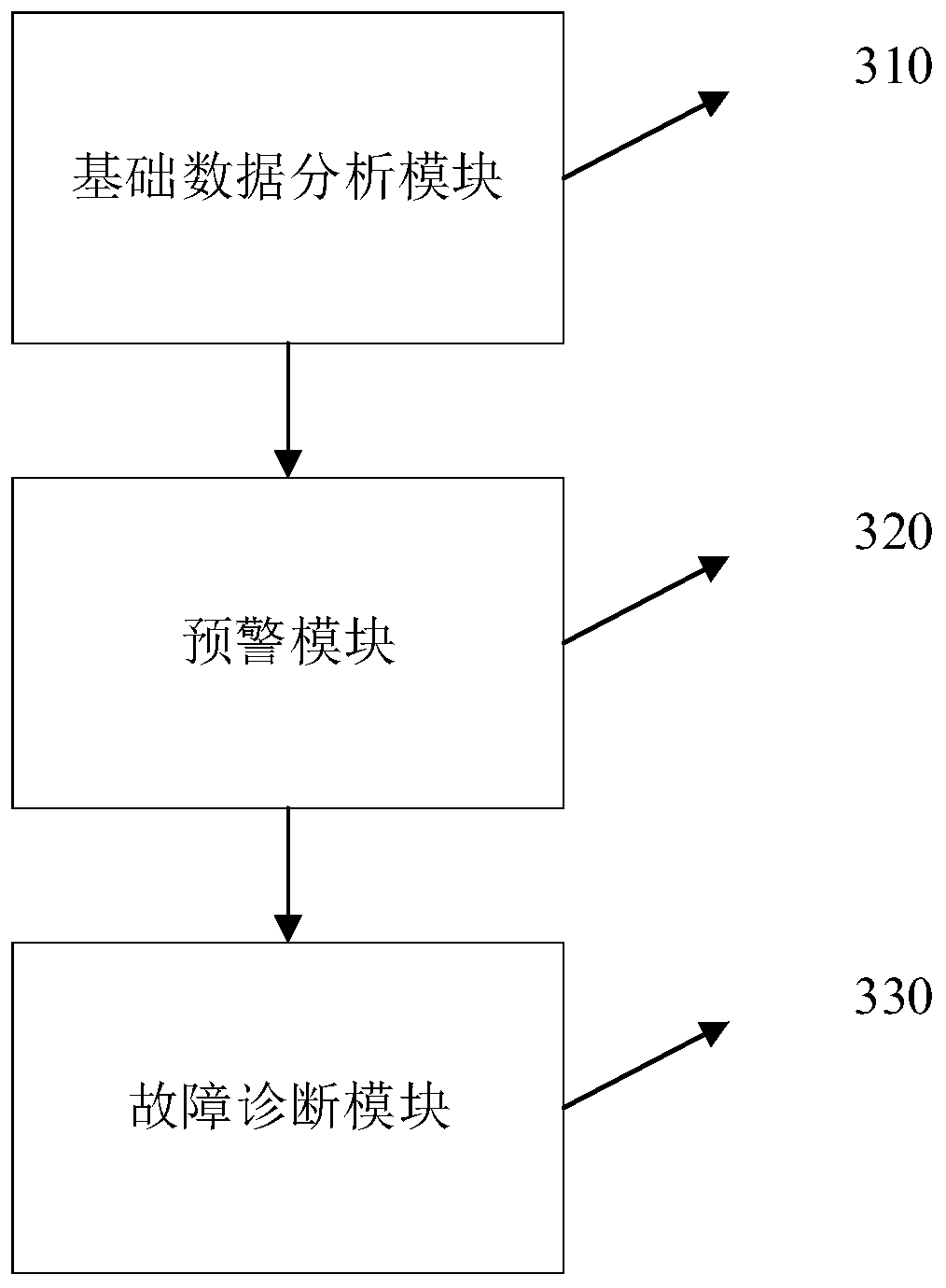

[0036] Step S430: Calculate and analyze the online monitoring data of the steam turbine lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com