Electric control system of coconut sheller

A coconut peeling machine, electric automatic control technology, applied in the direction of electric program control, general control system, control/adjustment system, etc., can solve the problems of operator injury, manual operation danger, low production efficiency, etc., to improve production Efficiency, automation, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

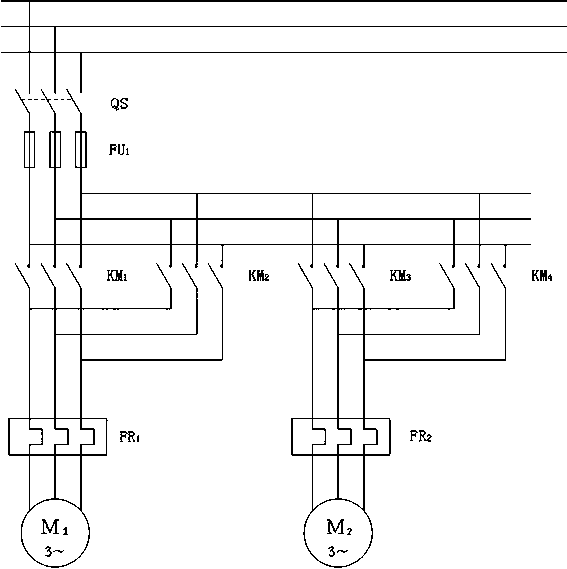

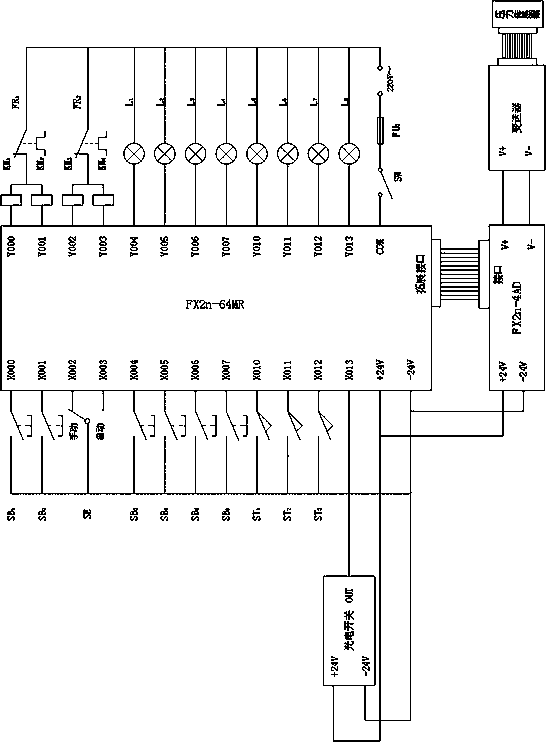

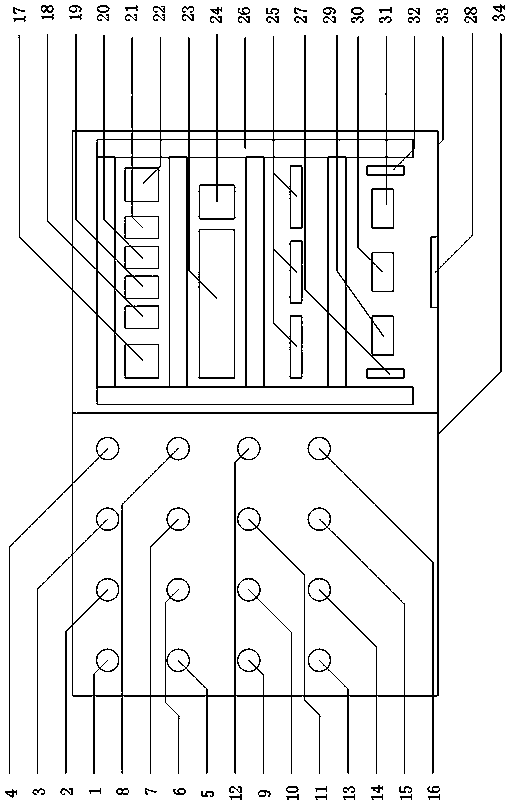

Method used

Image

Examples

Embodiment Construction

[0022] Automatic control mode: close the air switch QS17, turn the transfer switch SE11 to automatic, and the automatic indicator light L 3 3 is bright, the coconut is placed on the peeling machine tray 40, the photoelectric switch 41 detects that there is a coconut, and the photoelectric indicator light L 8 8 lights, process 1 indicator light L 5 5 bright. Press button SB 3 9. Start indicator light L 1 1 light, AC contactor KM 3 20 Coil energized, lower motor M 2 44 forward rotation, drive the pallet 40 to move upwards by the lower lead screw 43, during the upward movement of the coconut, the blade 35 is slowly pierced into the coconut coat, and the pressure sensor 39 is used to detect the depth of the blade 35 pierced into the coconut, and the blade 35 is pierced into the coconut shell. The pressure mutation signal of the coconut wood shell is used as the beginning of stripping. When the blade 35 pierces the coconut wood shell, the pressure detected by the pressure sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com