Cooling gas distribution device suitable for high-frequency plasma torch

A high-frequency plasma and cooling gas technology, applied in the direction of plasma, electrical components, etc., can solve the problems of frequent replacement of quartz tube walls, troubles in production experiments, and easy explosion, so as to reduce the work of frequent replacement of quartz tubes and stabilize The effect of fast air intake and uniform air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

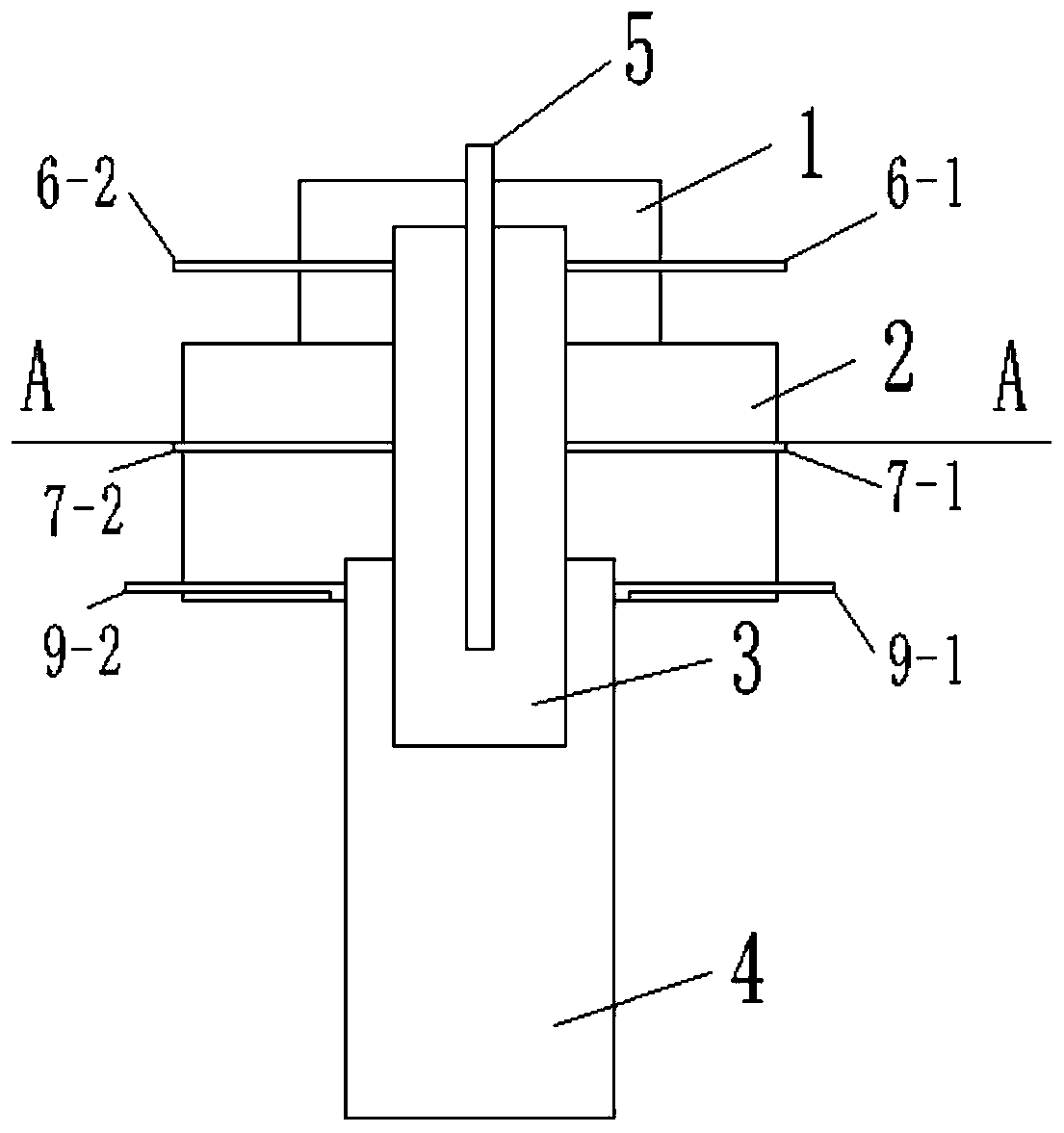

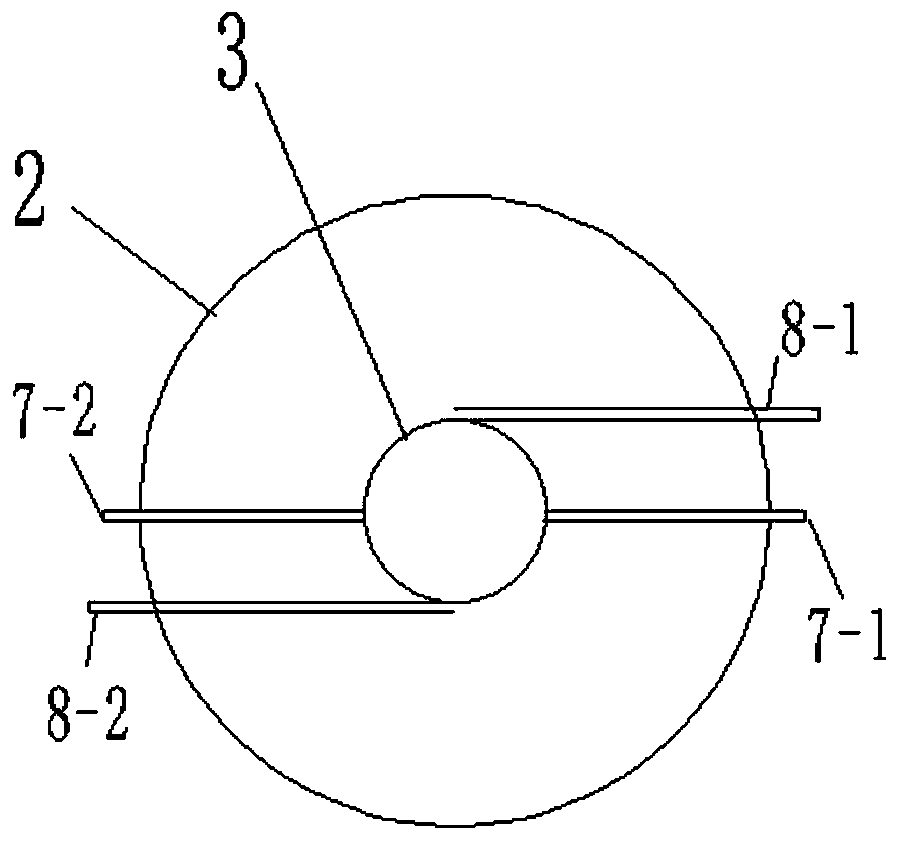

[0019] refer to figure 1 and figure 2 , a cooling gas distribution device suitable for high-frequency plasma torches, including an upper copper head 1, the upper copper head 1 and the lower copper head 2 are threaded, the upper copper head 1 and the lower copper head 2 It is a hollow structure, the inner wall of the hollow structure is provided with internal threads, and the outer wall of the inner quartz tube 3 is wrapped with thermal insulation asbestos, and then clamped on the inner threads of the inner wall of the hollow structure of the upper copper head 1 and the lower copper head 2, and the outer quartz tube 4 Wrapped with thermal insulation asbestos, it is clamped on the internal thread at the lower end of the hollow structure of the lower copper head 2, and the material gas pipe 5 is clamped in the center of the upper copper head 1, and the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com