Cross-linked polyolefin heat-shrinkable film with good printability and preparation method thereof

A technology of cross-linking poly and olefin heat, applied in the field of polyolefin heat shrinkable film, can solve the problems of falling, no longer suitable for printing, etc., and achieve the effect of stable surface tension and good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

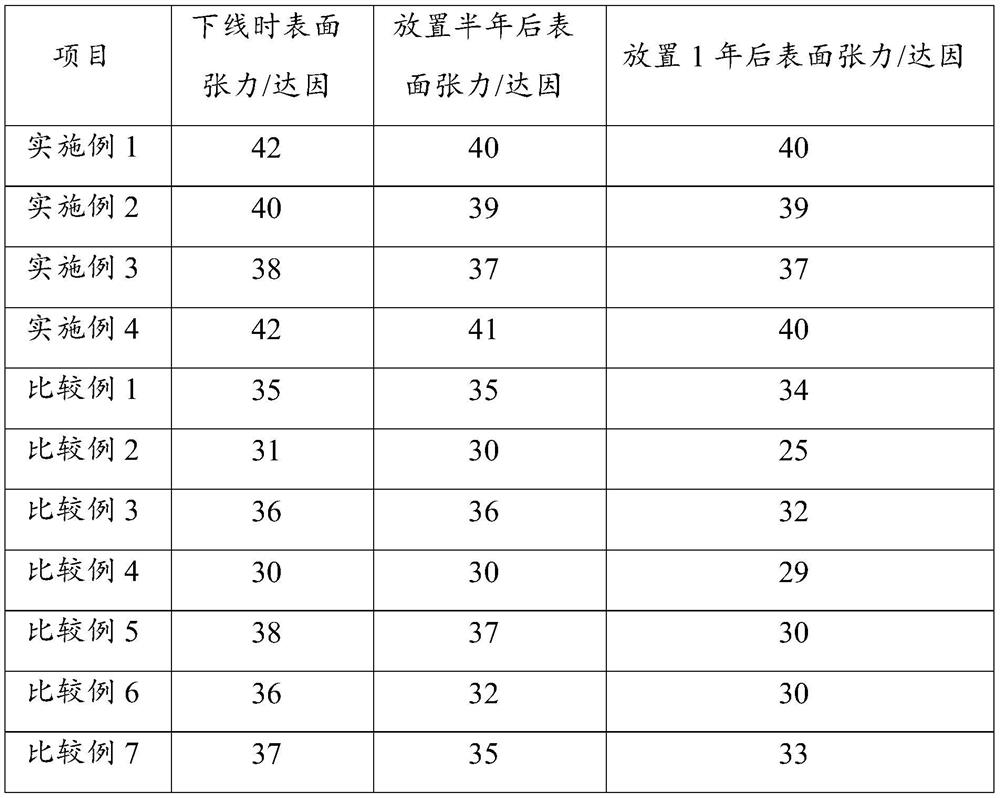

Examples

Embodiment 1

[0028] Raw material preparation:

[0029] Outer layer:

[0030] 65wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0031] 20wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0032] 10wt% maleic anhydride modified polyethylene (2.16kg pressure, 2g / 10min melt index at 190°C)

[0033] 5wt% silicone anti-blocking masterbatch;

[0034] Core layer:

[0035] 70wt% LDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0036] 20wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0037] 6wt% erucamide smooth masterbatch

[0038] 4wt% N,N-methylenebisacrylamide crosslinking initiator masterbatch;

[0039] inner layer:

[0040] 65wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0041] 30wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0042] 5wt% silicone anti-blocking masterbatch.

[0043] Preparation Process:

[0044] The raw materials of each layer are mixed in proportion and melted and plasticized with a screw e...

Embodiment 2

[0049] Outer layer:

[0050] 58.5wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0051] 35wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0052] 5wt% maleic anhydride modified polyethylene (2.16kg pressure, 2g / 10min melt index at 190°C)

[0053] 1.5wt% silicone anti-blocking masterbatch;

[0054] Core layer:

[0055] 60wt% LDPE (2.16kg pressure, melt index at 190°C is 1.5g / 10min)

[0056] 25wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0057] 10wt% erucamide smooth masterbatch

[0058] 5wt% N,N-methylenebisacrylamide crosslinking initiator masterbatch;

[0059] inner layer:

[0060] 63.5wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0061] 35wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0062] 1.5wt% silicone anti-blocking masterbatch.

[0063] Preparation Process:

[0064]The raw materials of each layer are mixed in proportion and melted and plasticized with a screw extruder respectively. The ...

Embodiment 3

[0069] Outer layer:

[0070] 65wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0071] 24wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0072] 7wt% maleic anhydride modified polyethylene (2.16kg pressure, 2g / 10min melt index at 190°C)

[0073] 4wt% silicone anti-blocking masterbatch;

[0074] Core layer:

[0075] 65wt% LDPE (2.16kg pressure, melt index at 190°C is 1.5g / 10min)

[0076] 20wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0077] 10wt% erucamide smooth masterbatch

[0078] 5wt% N,N-methylenebisacrylamide crosslinking initiator masterbatch;

[0079] inner layer:

[0080] 61.5wt% LDPE (2.16kg pressure, 0.5g / 10min melt index at 190°C)

[0081] 34wt% mLDPE (2.16kg pressure, 1.5g / 10min melt index at 190°C)

[0082] 4.5wt% silicone anti-blocking masterbatch.

[0083] Preparation Process:

[0084] The raw materials of each layer are mixed in proportion and melted and plasticized with a screw extruder respectively. The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com