Red water-soluble AgInS2 quantum dots and one-step synthesis method and application thereof

A water-soluble, quantum dot technology, applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., can solve problems such as mass production and promotion, and achieve strong controllability of results, huge application prospects, The effect of simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At a temperature of 200°C, a ratio of Ag, In, and S elements of 1:1:2, and a reaction time of 6 hours, red water-soluble AgInS was synthesized. 2 The quantum dot method is as follows:

[0034] 1) Weigh 116.9 mg of silver acetate, dissolve 381.9 mg of indium nitrate tetrahydrate in 50 ml of deionized water, and stir evenly to obtain a clear and transparent Ag and In precursor solution; then weigh 480 mg of sodium sulfide. water, poured into the above solution, the solution immediately reacted and turned into brown-black, and the magnetic stirring was even.

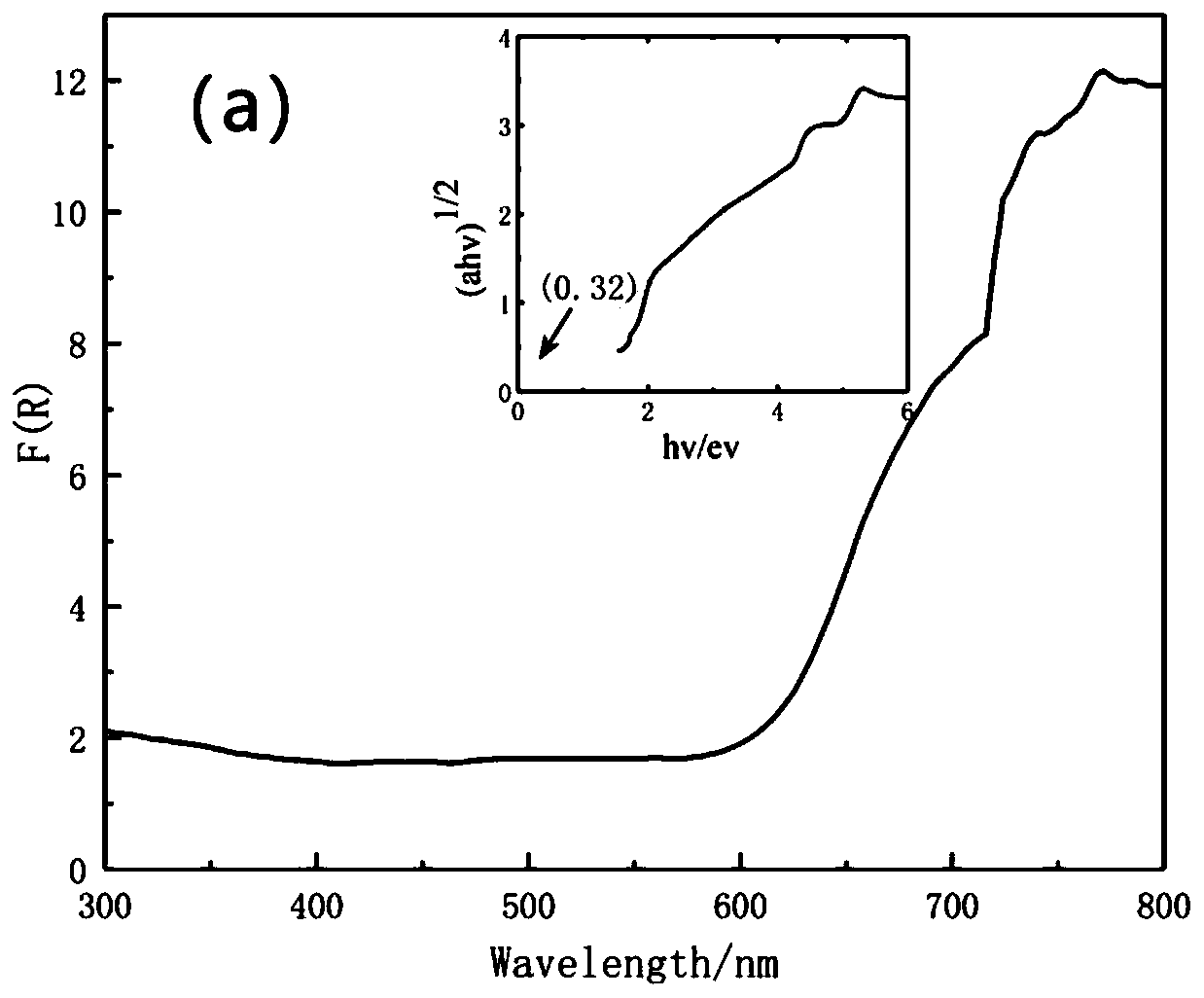

[0035] 2) Move the reacted solution to a reaction kettle, put the reaction kettle into a blast drying oven, set the reaction temperature to 200°C, and the reaction time to 6 hours to obtain a red solution in a natural state, and use fluorescence spectroscopy for sampling Fluorescence test was carried out with a photometer, and the sample was centrifuged and dried to obtain a powder for ultraviolet-visible absorption...

Embodiment 2

[0039] At a temperature of 200°C, a ratio of Ag, In, and S elements of 1:1:2, and a reaction time of 12 hours, red water-soluble AgInS was synthesized. 2 The quantum dot method is as follows:

[0040] The synthesis method of Example 2 is the same as that of Example 1, the difference is that the reaction time is increased to 12 hours, and the water-soluble AgInS which is red in natural state is obtained. 2 quantum dots. After the reaction is completed, samples are taken for fluorescence testing, centrifuged and dried to obtain a powder for XRD and UV-visible absorption testing.

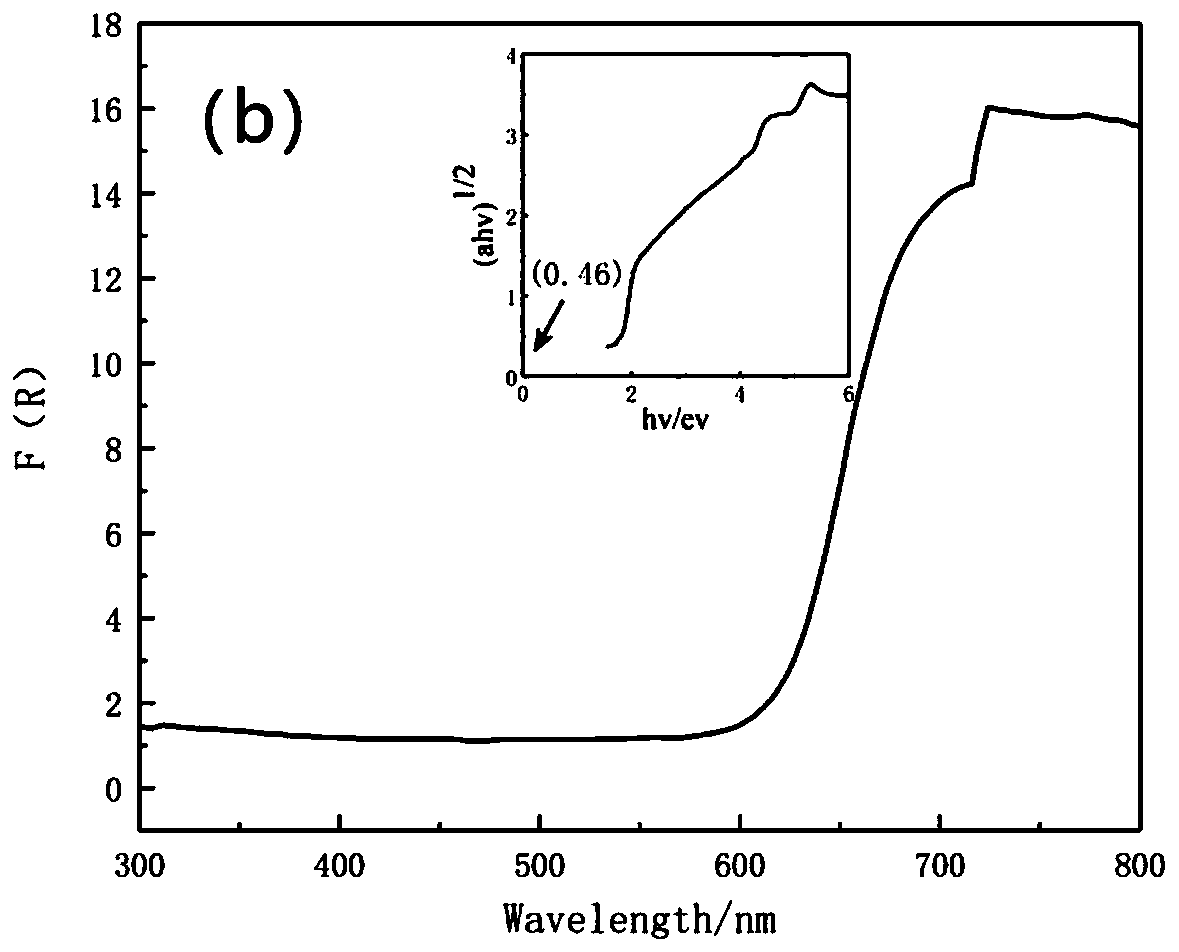

[0041] figure 2 AgInS prepared for Example 2 2 The UV-Vis diffuse reflectance spectrum of , the inset in the figure is the band gap diagram. It can be seen from the figure that the sample shows obvious reflection in the visible light range of 600-780nm, and shows a steep rise at the visible light absorption edge. This shows that the visible light absorption band is transformed by the band gap, not...

Embodiment 3

[0047] At a temperature of 200°C, a ratio of Ag, In, and S elements of 1:1:2, and a reaction time of 24 hours, red water-soluble AgInS was synthesized. 2 The quantum dot method is as follows:

[0048] The synthesis method of Example 3 is the same as that of Example 1, and the reaction time is increased to 24 hours to obtain a red solution in a natural state. Samples are taken for fluorescence testing, samples are centrifuged and dried, and powders are obtained for UV-visible absorption testing.

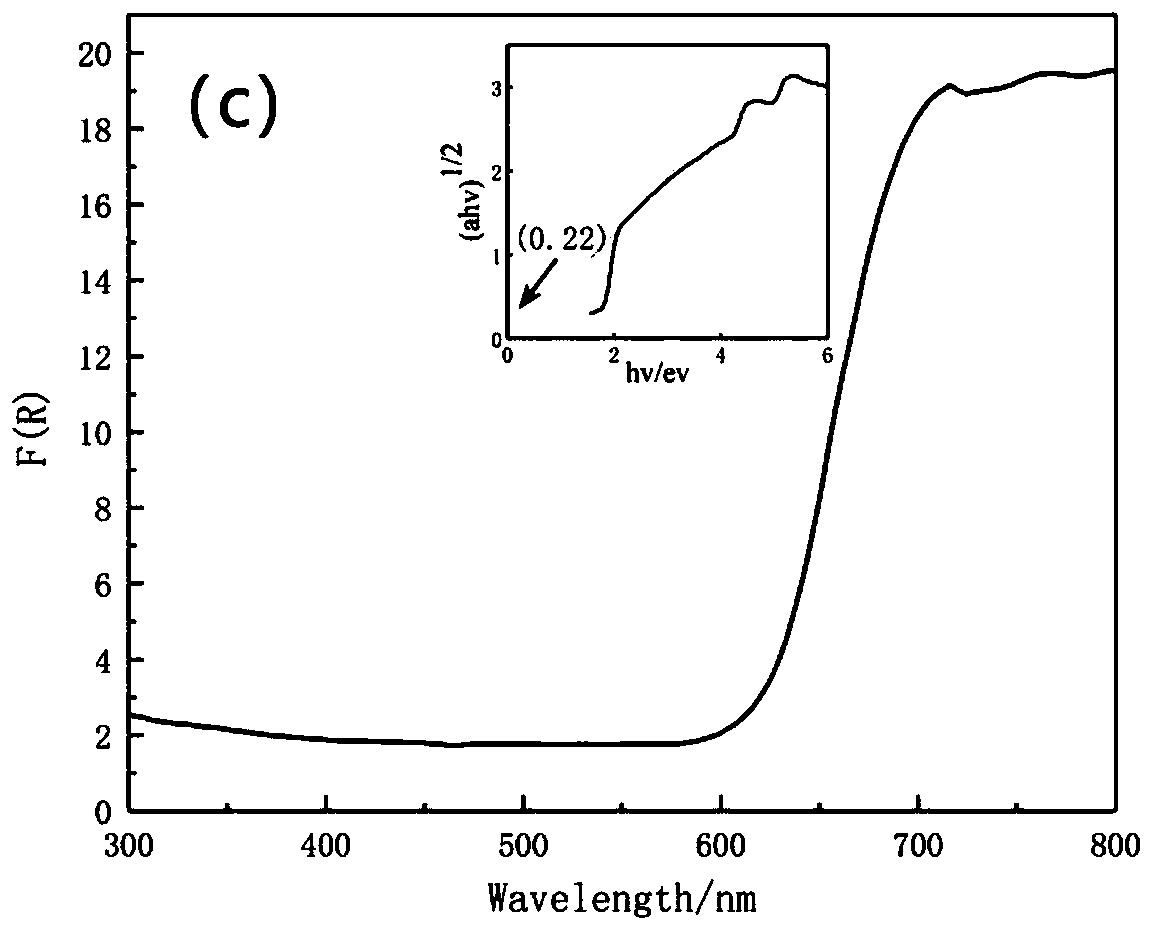

[0049] image 3 AgInS prepared for Example 3 2 The UV-Vis diffuse reflectance spectrum of , the inset is the bandgap diagram. It can be seen from the figure that the sample shows obvious reflection in the visible light range of 600-780nm, and shows a steep rise shape at the visible light absorption edge. This shows that the visible light absorption band is transformed by the band gap, not by the impurity energy level. According to the Kubelka-Munk formula, the intersection of the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap