Preparation method of spherical carboxymethyl cellulose barium stephenate based on added seed crystals

A technology of carboxymethyl cellulose and sodium carboxymethyl cellulose, which is applied in the direction of offensive equipment, ignition devices, explosives, etc., can solve the problem of low pass rate and achieve the goal of improving pass rate, shortening induction period, and shortening synthesis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

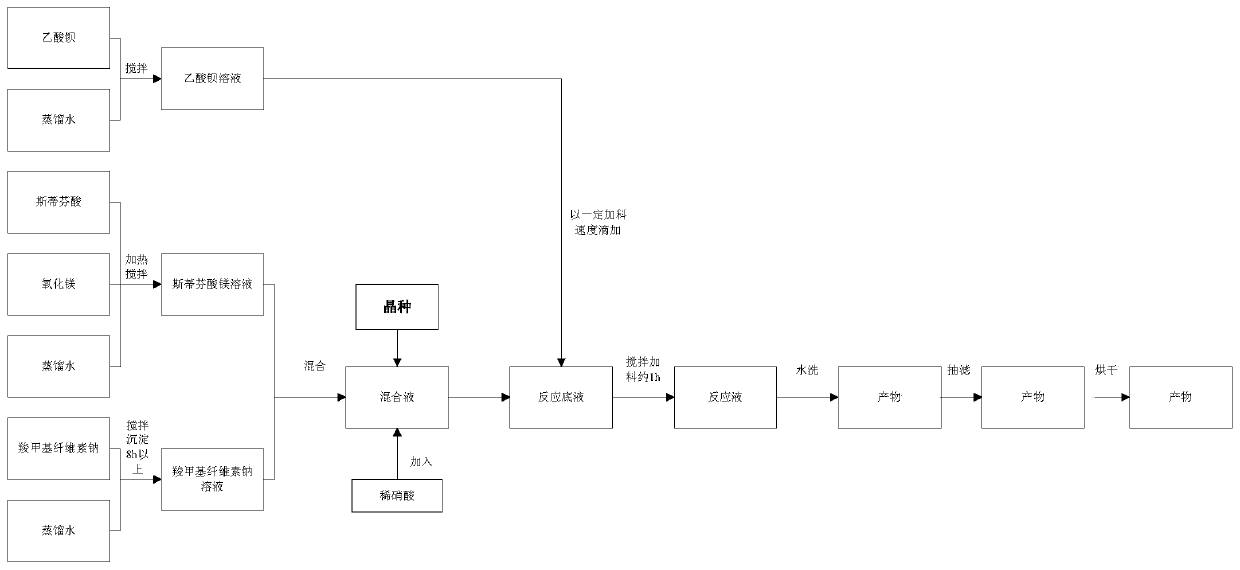

Method used

Image

Examples

Embodiment 1

[0050] Specific steps are as follows:

[0051] (1) Prepare a solution with a mass concentration of 0.5% sodium carboxymethylcellulose (sodium carboxycellulose for short): weigh 10 g of sodium carboxymethylcellulose, add 1990 ml of distilled water, and stir to dissolve the precipitate for more than 8 hours;

[0052] (2) preparation mass concentration is 16% barium acetate solution: take by weighing 586.7g barium acetate, add 3080ml distilled water, stir and dissolve under the situation of heating;

[0053] (3) preparation of 7% magnesium stephenate solution: take by weighing 423g stephenate (assuming that the purity of stephenate is 100%, conversion should be carried out when it is less than 100%), add 5600ml distilled water, stir and dissolve under heating;

[0054] Add (70-80) g magnesium oxide (slightly excessive) into the stephanic acid solution, and stir under heating until the magnesium oxide is added and no longer reacts to generate a stephenic acid magnesium solution; ...

Embodiment 2

[0065] Specific steps are as follows:

[0066] (1) Prepare a solution with a mass concentration of 0.4% sodium carboxymethyl cellulose (abbreviated as sodium carboxycellulose): weigh 8 g sodium carboxycellulose, add 1990 ml of distilled water, and stir to dissolve the precipitate for more than 8 hours;

[0067] (2) preparation mass concentration is 15.5% barium acetate solution: take by weighing 565.0g barium acetate, add 3080ml distilled water, stir and dissolve under the situation of heating;

[0068] (3) preparation of 6.5% magnesium stephenate solution: take by weighing 389g stephenate (assuming that the purity of stephenate is 100%, conversion should be carried out when it is less than 100%), add 5600ml distilled water, stir and dissolve under heating;

[0069] Add (70-80) g magnesium oxide (slightly excessive) into the stephanic acid solution, and stir under heating until the magnesium oxide is added and no longer reacts to generate a stephenic acid magnesium solution; ...

Embodiment 3

[0080] Specific steps are as follows:

[0081] (1) Prepare a solution with a mass concentration of 0.6% sodium carboxymethylcellulose (abbreviated as sodium carboxycellulose): weigh 12 g sodium carboxycellulose, add 1990 ml of distilled water, and stir to dissolve the precipitate for more than 8 hours;

[0082] (2) preparation mass concentration is 16.5% barium acetate solution: take by weighing 608.6g barium acetate, add 3080ml distilled water, stir and dissolve under the situation of heating;

[0083] (3) preparation of 7.5% magnesium stephenate solution: take by weighing 454g stephenate (assuming that the purity of stephenate is 100%, conversion should be carried out when it is less than 100%), add 5600ml distilled water, stir and dissolve under heating;

[0084] Add (70-80) g magnesium oxide (slightly excessive) into the stephanic acid solution, and stir under heating until the magnesium oxide is added and no longer reacts to generate a stephenic acid magnesium solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com