Adhesive for tipping paper for cigarettes and preparation method of adhesive

A technology of tipping paper and adhesive for cigarettes, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc. Poor and other problems, to achieve the effect of increasing cohesive strength and adhesion properties, good adhesion properties, and good flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An adhesive for cigarette tipping paper, made from the following raw materials in parts by weight:

[0052] 60-70 parts of butyl acrylate, 20-25 parts of vinyl acetate, 12-16 parts of hydroxypropyl acrylate, 6-9 parts of dimethylaminoethyl acrylate, 5-8 parts of 2-acetamidoacrylic acid, azobis 1.7-2.1 parts of isobutyronitrile, 60-80 parts of mixed solvent.

[0053] Preferably, the adhesive for cigarette tipping paper is made of the following raw materials in parts by weight: 65 parts of butyl acrylate, 23 parts of vinyl acetate, 14.5 parts of hydroxypropyl acrylate, 7.5 parts of dimethylaminoethyl acrylate, 6.8 parts of 2-acetaminoacrylic acid, 1.9 parts of azobisisobutyronitrile, and 72 parts of mixed solvent.

[0054] The present invention also provides a method for preparing the adhesive for cigarette tipping paper, comprising the following steps:

[0055] S1: Weigh respectively by weight: butyl acrylate, vinyl acetate, hydroxypropyl acrylate, dimethylaminoethyl a...

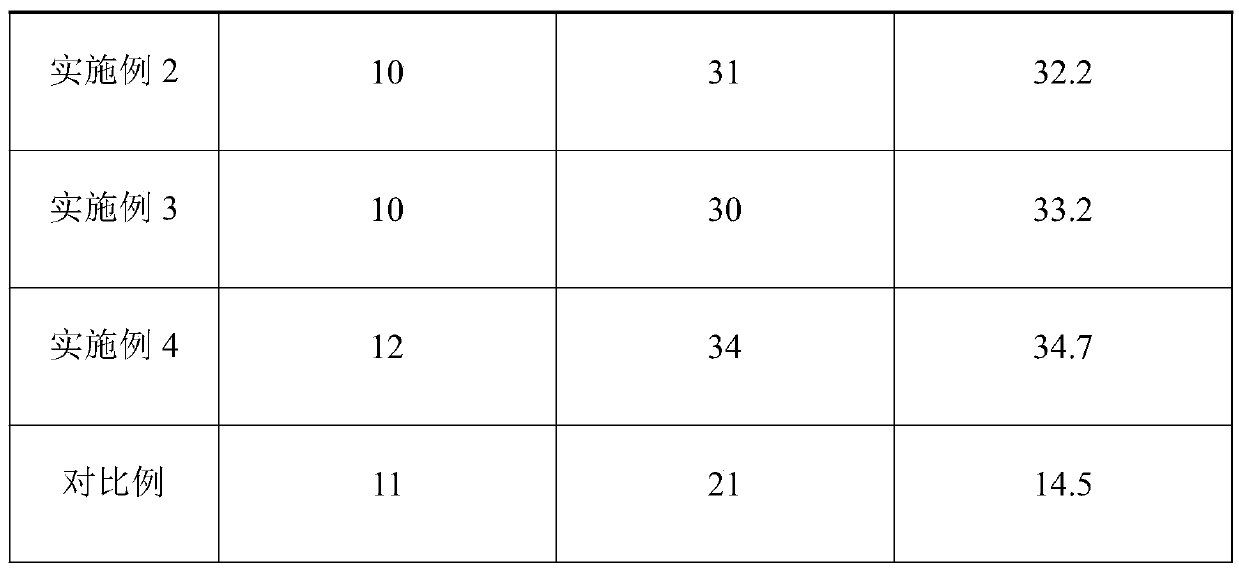

Embodiment 2

[0068] An adhesive for cigarette tipping paper, made from the following raw materials in parts by weight:

[0069] 60 parts of butyl acrylate, 20 parts of vinyl acetate, 12 parts of hydroxypropyl acrylate, 6 parts of dimethylaminoethyl acrylate, 5 parts of 2-acetamidoacrylic acid, 1.7 parts of azobisisobutyronitrile, 60 parts of mixed solvent .

[0070] In the present embodiment, the preparation method of the adhesive for cigarette tipping paper comprises the following steps:

[0071] S1: Weigh respectively by weight: butyl acrylate, vinyl acetate, hydroxypropyl acrylate, dimethylaminoethyl acrylate, 2-acetamidoacrylic acid, azobisisobutyronitrile and mixed solvent;

[0072] S2: Dissolve azobisisobutyronitrile with a small amount of mixed solvent to obtain azobisisobutyronitrile solution, which is set aside;

[0073] S3: Put all the vinyl acetate, hydroxypropyl acrylate, dimethylaminoethyl acrylate, 2-acetamidoacrylic acid, 1 / 3 of butyl acrylate and half of the mixed solvent...

Embodiment 3

[0084] An adhesive for cigarette tipping paper, made from the following raw materials in parts by weight:

[0085]70 parts of butyl acrylate, 25 parts of vinyl acetate, 16 parts of hydroxypropyl acrylate, 9 parts of dimethylaminoethyl acrylate, 8 parts of 2-acetamidoacrylic acid, 2.1 parts of azobisisobutyronitrile, 80 parts of mixed solvent .

[0086] In the present embodiment, the preparation method of the adhesive for cigarette tipping paper comprises the following steps:

[0087] S1: Weigh respectively by weight: butyl acrylate, vinyl acetate, hydroxypropyl acrylate, dimethylaminoethyl acrylate, 2-acetamidoacrylic acid, azobisisobutyronitrile and mixed solvent;

[0088] S2: Dissolve azobisisobutyronitrile with a small amount of mixed solvent to obtain azobisisobutyronitrile solution, which is set aside;

[0089] S3: Put all the vinyl acetate, hydroxypropyl acrylate, dimethylaminoethyl acrylate, 2-acetamidoacrylic acid, 1 / 3 of butyl acrylate and half of the mixed solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com