European metallurgical cloth bag ash-collecting storehouse high-temperature ash cooling device

A cooling device and cloth bag technology, applied in the direction of furnaces, shaft furnaces, furnace types, etc., can solve problems affecting the normal production of bag dust collectors, increase the workload of bag dust collectors, increase the ash temperature and ash volume of bag dust collectors, and achieve cost reduction The effect of low, increased contact area, and accelerated heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

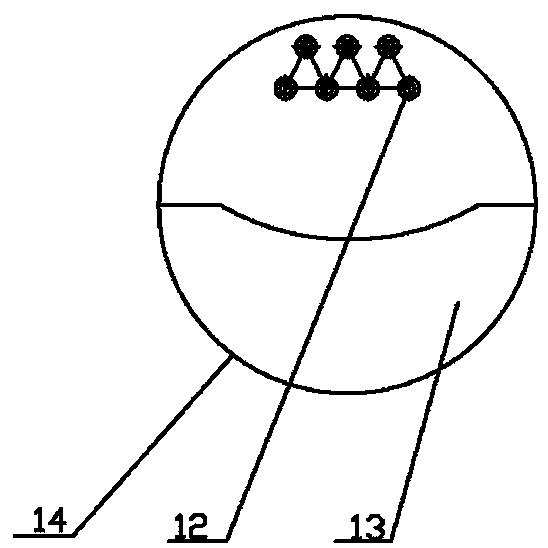

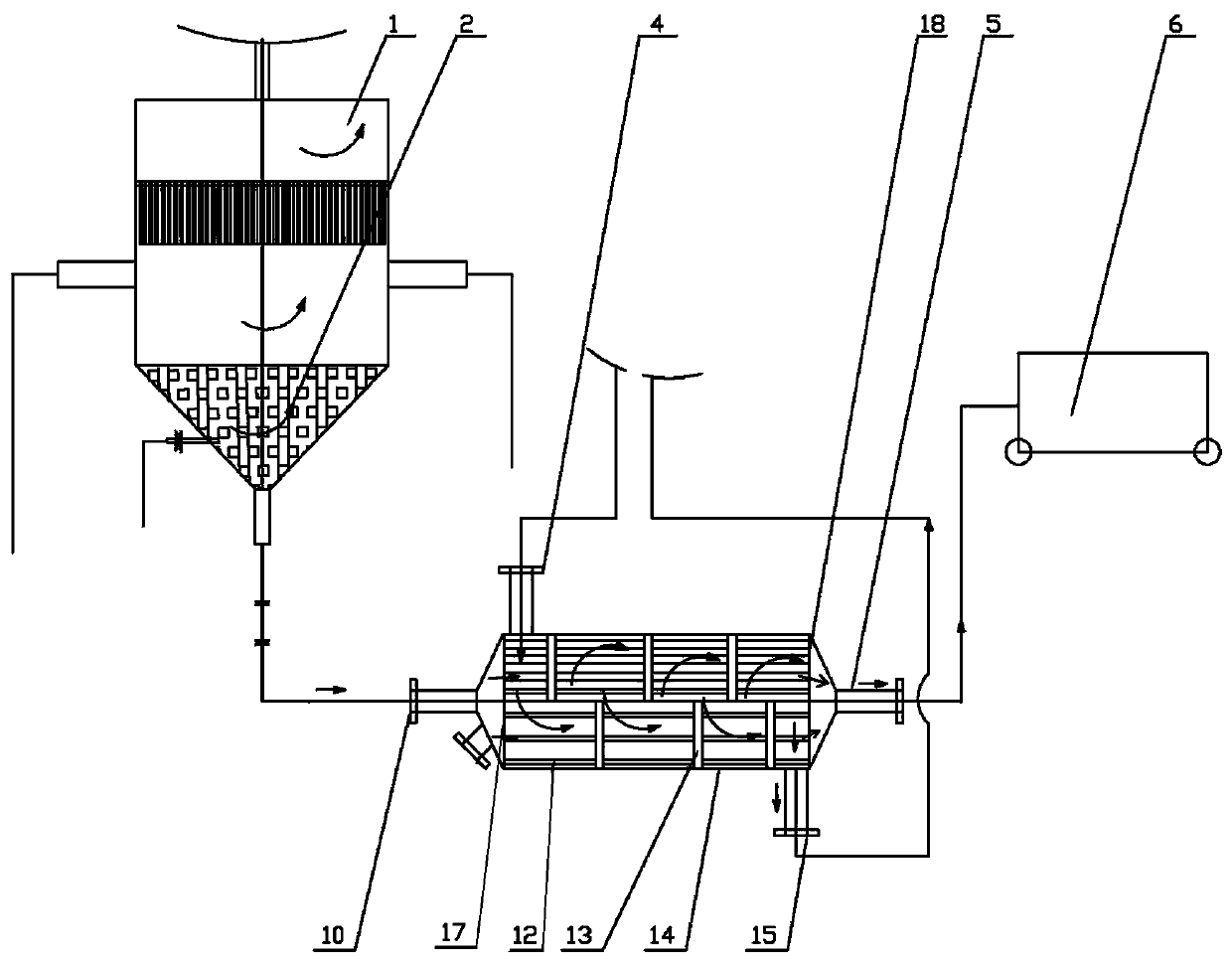

[0012] A high-temperature ash cooling device for the bag ash collection bin of Ouyeel furnace, such as figure 1 , figure 2 As shown, it includes the cooling device body 14, the middle part of the cooling device body 14 is cylindrical, the two ends of the cooling device body 14 are conical, and the two ends of the cooling device body 14 are respectively provided with closed partitions 17, 18, and the closed partition 17 18 and 18 are horizontally spaced with ash conveying pipes 12, and the adjacent ash conveying pipes 12 are arranged in an equilateral triangle. The cooling medium inlet 4 is arranged on the top surface of the cooling device body of the pipe, and the cooling device outlet 15 is arranged under the bottom surface of the cooling device body close to the ash discharge pipe. The baffle baffles 13 are arranged at intervals up and down in the cooling device body. The top or bottom surface of the baffle plate 13 has an arc-shaped notch, and the arch height of the notch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap