Fiber with anti-fogging effect and pocket applying same

A fiber and anti-fog technology, which is applied in the field of clothing manufacturing, can solve the problems of anti-fog treatment and the inability to adjust the lens in time, and achieve good penetration, good anti-fog effect, and not easy to lose or volatilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] The embodiment of the present invention discloses a fiber with anti-fog effect, the surface of the fiber is coated with a microcapsule anti-fog agent layer, and the microcapsule anti-fog agent layer includes several microcapsules containing anti-fog The mist includes the following components in weight percentage: fatty alcohol polyoxyethylene ether sodium sulfate 1.0-16.0%, nonylphenol polyoxyethylene ether 0.2-5.0%, alkylbenzene sulfonate sodium 3.0-8.0%, octylphenol polyoxyethylene ether Oxyethylene ether 1.0-10.0%, polyethylene glycol 1000 0.5-2.0%, polyoxyethylene laurate 1.0-5.0%, alkanolamide 2.0%-5.0%, polyoxyethylene sorbitan monostearate 2.0-15%, Casson 0.01-1.0%, and the balance is deionized water.

[0025] As an improvement to the above solution, the microcapsule component of the embodiment of the present invention further includes: 0.1-3.0% sorbic acid, and 10.0-15.0% water-soluble silicone oil. Sorbic acid has good antibacterial properties, which can ensur...

no. 2 example

[0030] An embodiment of the present invention provides a pocket, which is wholly or partly woven from the anti-fogging fiber described in the above embodiment.

[0031] The aforementioned pocket includes a folded towel disposed in the bag body, the root of the folded towel is connected to the pocket opening, and the folded towel is woven from the fiber with anti-fog effect. When the folded towel is in the storage state, the folded towel is in the pocket and is not easy to find, which ensures the integration effect of the clothes. When the folded towel is in use, the user can turn the folded towel out of the pocket and wipe the lens . Since the collar angle and the pocket are integrated, the utility model has the advantages of simple structure, convenient manufacture and low cost.

no. 3 example

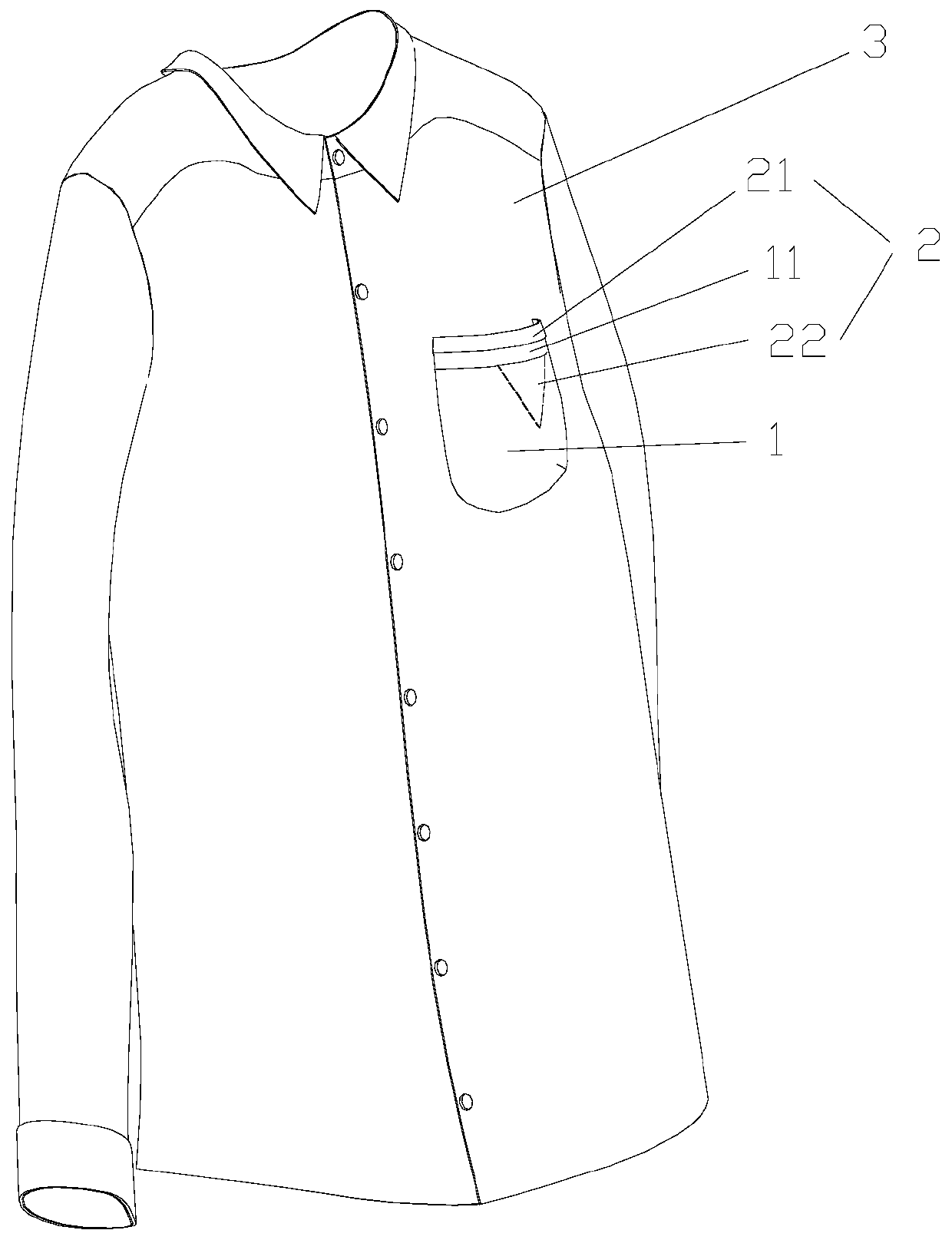

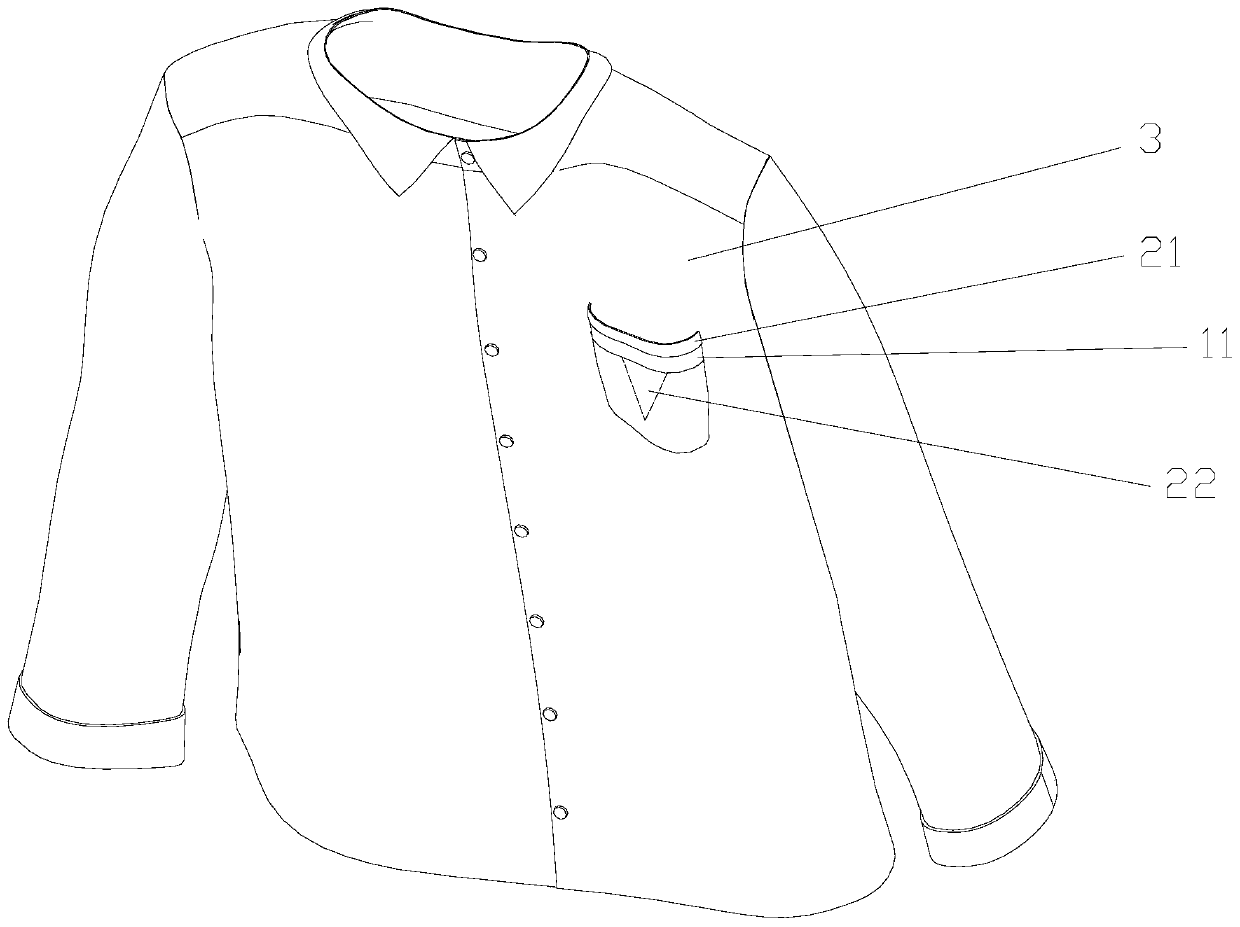

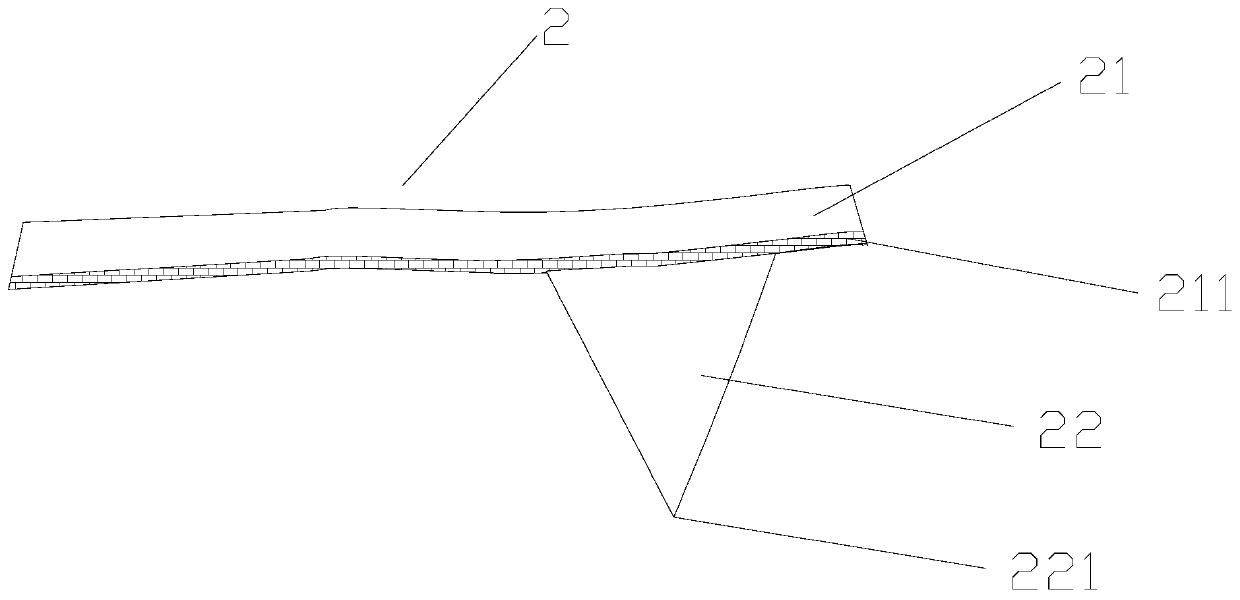

[0033] Please refer to Figures 1 to 3 As shown, the difference from the above-mentioned second embodiment is that in this embodiment, the above-mentioned pocket 1 also includes a wiping strip 2 arranged on one side of the mouth of the bag, and the wiping strip 2 includes a detachable connection to the The bonding part 21 at the mouth of the bag, and the wiping part 22 arranged at the end of the bonding part 21, the wiping part 22 is woven from the fiber with anti-fog effect, when the bonding part 21 is attached When at the pocket opening of the pocket 1, the wiping part 22 is located inside the pocket.

[0034] In this embodiment, the wiping strip 2 is bonded to the inner side of the pocket opening relative to the jacket 3, so that when the wiping strip 2 is torn off from the pocket opening, the wiping part 22 is located in front of the user, which is convenient for the user to wipe the lens.

[0035] The matching portion 11 is formed at the corresponding position of the adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap