A kind of preparation method of high transmittance hydrophobic coating film for photovoltaic glass

A high light transmittance, photovoltaic glass technology, applied in the direction of coating, etc., can solve the problems that need to be further improved, and achieve the effect of improving photoelectric conversion efficiency, increasing light transmittance, and single equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

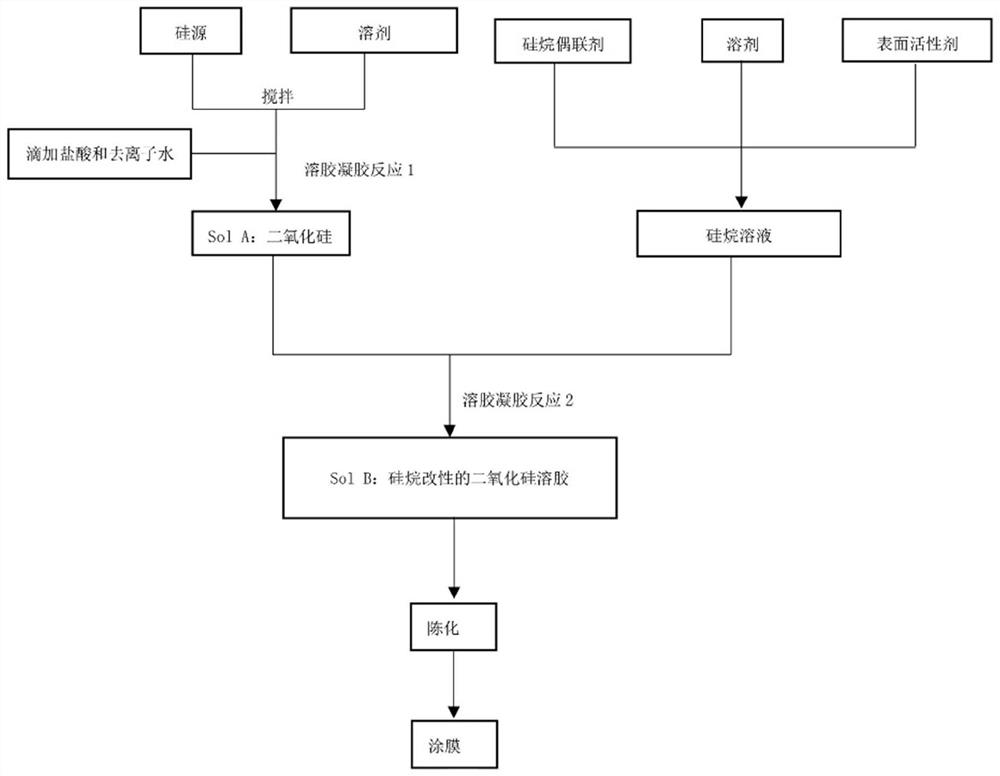

[0034] Such as figure 1 Shown, a kind of preparation method for the high transmittance hydrophobic coating film of photovoltaic glass comprises the following steps:

[0035] (1) Add 41.67g (0.2mol) of ethyl orthosilicate, 120.2g (2mol) of isopropanol, and 9g (0.5mol) of deionized water into a three-necked flask, mix and stir, add hydrochloric acid to adjust the pH to 2-3, and stir Under reaction for 4 hours, the silica sol with an average particle size of about 10nm was obtained;

[0036](2) Raise the temperature to 60°C, add 3.1g of perfluorodecyltriethoxysilane, 146.9g of isopropanol, 4.8g of ethylene glycol butyl ether, and 0.03g of polyethylene glycol octylphenyl ether, and stir Stop the reaction after 6 hours of reaction, wait until the temperature drops to room temperature, take out and filter to obtain a mixed sol B with a solid content of 10%-20% and an average particle size of 15nm (the pot life is 6-8 months);

[0037] (3) Aging for 1-7d for use, the substrate is m...

Embodiment 2

[0042] A method for preparing a hydrophobic coating film with high light transmittance for photovoltaic glass, comprising the following steps:

[0043] (1) Add 41.67g (0.2mol) of ethyl orthosilicate, 108.2g (1.8mol) of isopropanol, and 9g (0.5mol) of deionized water into a three-necked flask, mix and stir, add hydrochloric acid to adjust the pH to 2-3, React for 4 hours under stirring to obtain a silica sol with an average particle size of about 20 nm;

[0044] (2) Raise the temperature to 60°C, add 3.1g of perfluorodecyltriethoxysilane, 146.9g of isopropanol, 4.8g of butyl glycol ether, and 0.03g of polyethylene glycol octylphenyl ether and stir Stop the reaction after reacting for 6 hours, wait until the temperature drops to room temperature, take out and filter to obtain a mixed sol B with a solid content of 10%-20% and an average particle size of 25nm (the pot life is 6-8 months);

[0045] (3) Aging for 1-7d for use, the substrate is made of solar photovoltaic glass of 30...

Embodiment 3

[0048] A method for preparing a hydrophobic coating film with high light transmittance for photovoltaic glass, comprising the following steps:

[0049] (1) Add 41.67g (0.2mol) of ethyl orthosilicate, 73.6g (1.6mol) of absolute ethanol, and 9g (0.5mol) of deionized water into a three-necked flask, mix and stir, add hydrochloric acid to adjust the pH to 2-3, React for 4 hours under stirring to obtain a silica sol with an average particle size of about 15 nm;

[0050] (2) Raise the temperature to 60°C, add 13.12g of n-decyltrimethoxysilane, 35.43g of absolute ethanol, and 0.03g of polyethylene glycol octylphenyl ether, and stop the reaction after stirring for 6 hours. to room temperature, take out and filter to obtain a mixed sol B with a solid content of 10%-20% and an average particle size of 20nm (the pot life is 6-8 months);

[0051] (3) Aging for 1-7d for use, the substrate is made of solar photovoltaic glass of 30mm×30mm, spin-coated at a speed of 5000rpm / min for 60s with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

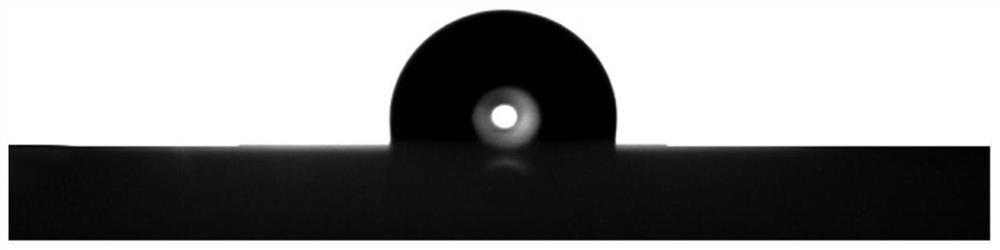

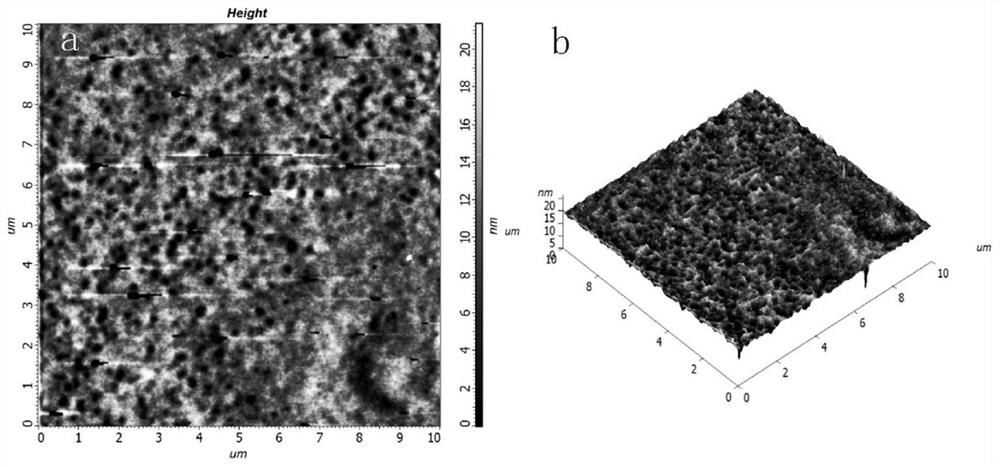

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com