A kind of light function multi-conversion plastic greenhouse composite film and its preparation method

A composite film and plastic greenhouse technology, applied in botany equipment and methods, greenhouse cultivation, horticulture, etc., to achieve the effects of improving greenhouse effects, prolonging service life, promoting early maturity and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

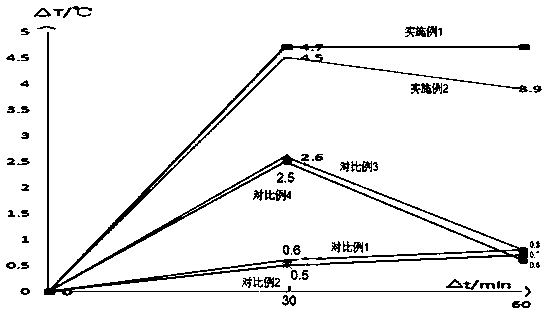

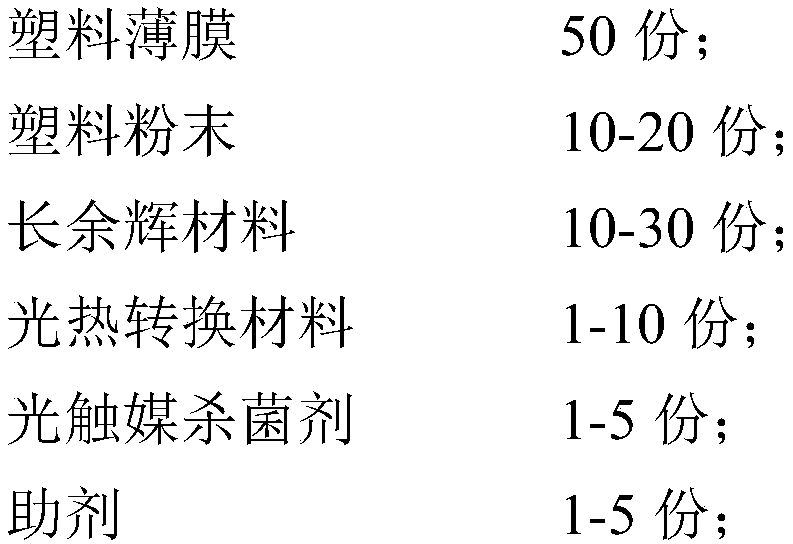

Embodiment 1

[0036] According to the formula in Table 1, the long afterglow material, the photothermal conversion material, the photocatalyst bactericide, the anti-aging agent, and the polyethylene powder are mixed uniformly with a powder disperser. On a square polyethylene film (about 1.00 g) with a side length of 15 cm, each uniformly mixed inorganic nano-powder and polyethylene powder were uniformly applied to obtain a powder film. Place the powder film in a steel plate frame with a 15cm side of the inner frame and a 17cm side of the outer frame, add PET anti-film on the upper and lower sides, and add two steel plates on the upper and lower sides; The mold and powder film / PET release film / steel plate" are sandwiched into the hot press in turn, and under the conditions of temperature 99-120 ℃ and pressure 35-50MPa, the hot-press hot-rolling compound of the film is carried out, and the composite film is obtained for use.

Embodiment 2

[0038] According to the formula in Table 1, a powder film was prepared in the same manner as in Example 1.

[0039] Set PET anti-film on the upper and lower sides of the film, and add two steel plates on the top and bottom; sandwich the film and surface powder into the hot-pressing plate in turn according to the method of "steel plate / PET anti-film / powder film / PET anti-film / steel plate", and the hot-rolled The plate is put into a blast drying oven, and the film is hot-rolled and compounded under the conditions of a temperature of 165-185 ° C and a pressure of 35-50 MPa, and the compound film is obtained after 2 hours for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com