Flexible multilayer frequency selective surface with transmission zero point

A technology of frequency selective surface and transmission zero point, applied in electrical components, antennas and other directions, it can solve the problems of unstable out-of-band selectivity of single-frequency point passband, difficult to meet the needs of equipment with different shapes, and large thickness, etc., to improve the shape The effect of deformation adaptability, improvement of out-of-band selection characteristics, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

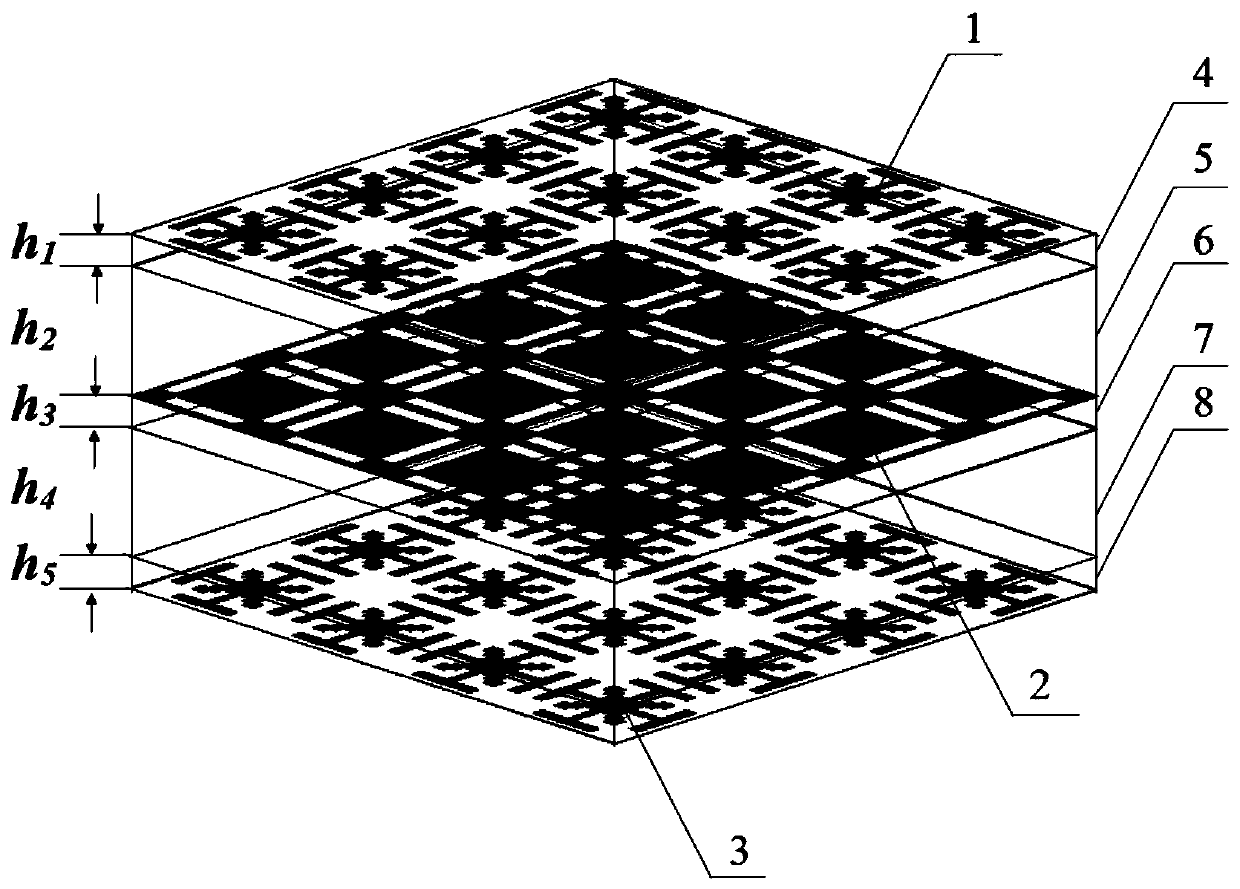

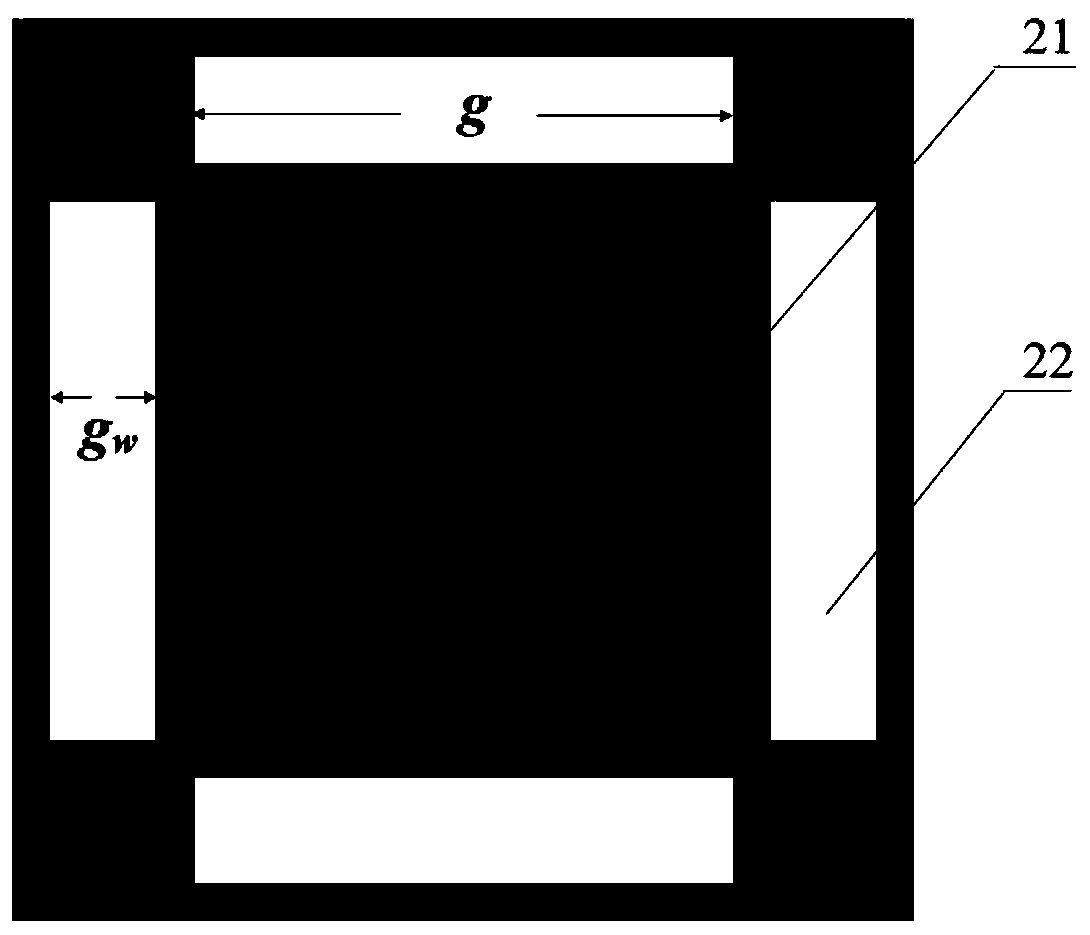

[0036] In this example, the side length p of each unit on the top metal patch resonant layer 1 and the bottom metal patch resonant layer 3 is the same as the side length p of each square unit on the slot coupling metal patch middle layer 2, that is, the side length p=3mm, length g=2mm of rectangular slit 22, wide g w =0.4mm, distance l between two adjacent rectangular slits 22 4 =2mm, the thickness h of the first dielectric substrate 4 1 =0.05mm, the second dielectric substrate 5 thickness h 2 =0.3mm, the thickness h of the third dielectric substrate 6 3 =0.05mm, thickness h of the fourth dielectric substrate 7 4 =0.3mm, the thickness h of the fifth dielectric substrate 8 5 = 0.05 mm.

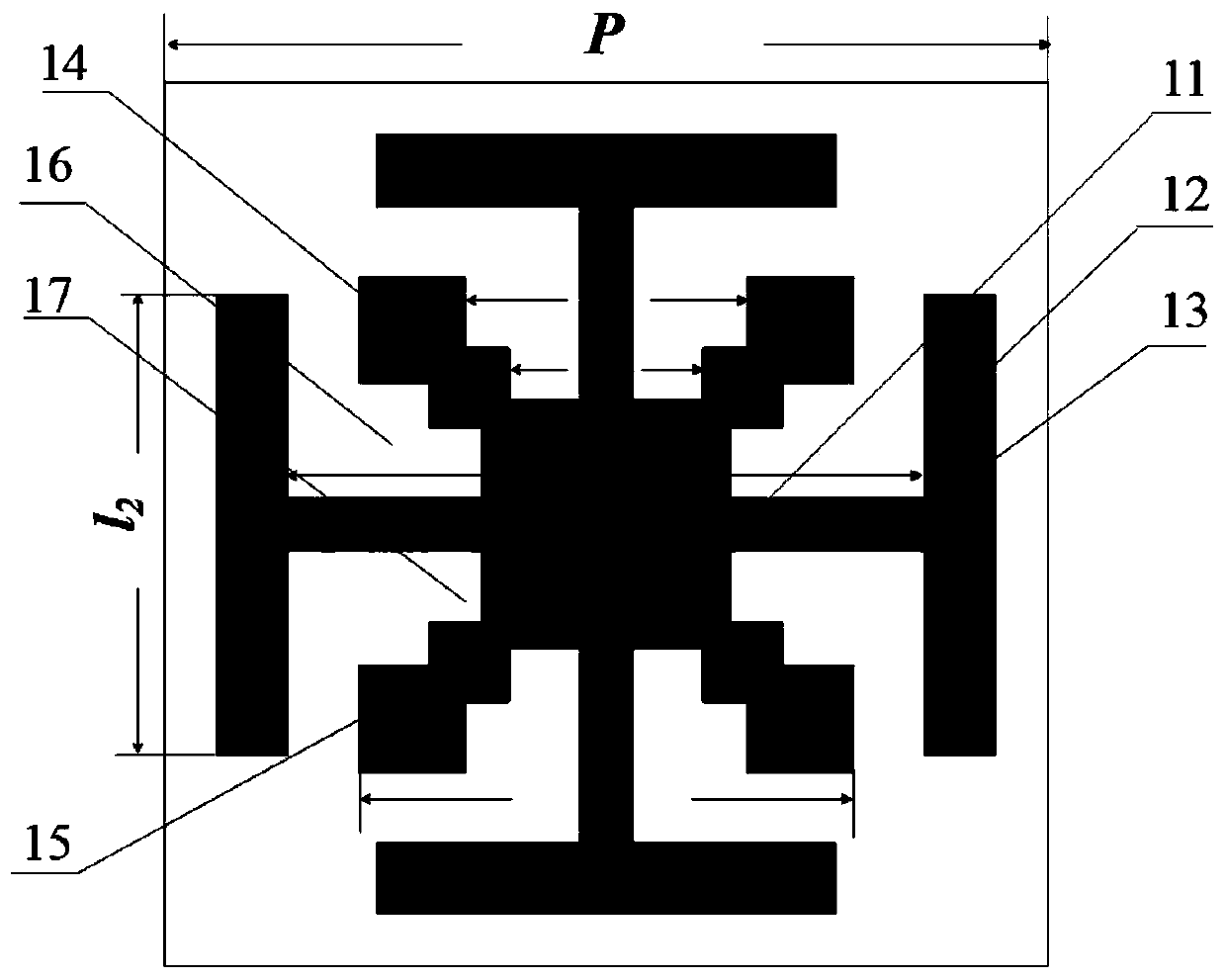

[0037] In this example, the parameter design of Jerusalem cross 11 and fractal structure 14 is divided into the following two special cases:

[0038] The rectangular metal strip 12 on top of the cross metal strip in the first case is l 2 =1.9mm, width w 2 =0.2mm, cross metal strip 13 lo...

Embodiment 2

[0042] In this example, the side length p of each unit on the top metal patch resonant layer 1 and the bottom metal patch resonant layer 3 is the same as the side length p of each square unit on the slot coupling metal patch middle layer 2, that is, the side length p=3mm, the length of the rectangular metal strip 12 on the top of the cross metal strip is l 2 = 1.7mm, width w 2 =0.2mm, cross metal strip 13 long l 1 = 2.4mm, width w 1 =0.2mm, the side length l of the square metal patch 15 in the fractal structure 14 3 =1.9mm, the second-level rectangular groove 17 width d 2 =0.7mm, the first level of rectangular groove 16 width d 1 =1.2mm, the thickness h of the first dielectric substrate 4 1 =0.05mm, the second dielectric substrate 5 thickness h 2 =0.3mm, the thickness h of the third dielectric substrate 6 3 =0.05mm, thickness h of the fourth dielectric substrate 7 4 =0.3mm, the thickness h of the fifth dielectric substrate 8 5 = 0.05 mm.

[0043] In this example, the...

Embodiment 3

[0048] In this example, the side length p of each unit on the top metal patch resonant layer 1 and the bottom metal patch resonant layer 3 is the same as the side length p of each square unit on the slot coupling metal patch middle layer 2, that is, the side length p=3mm, cross metal strip 13 long l 1 =2.2mm, width w 1 =0.15mm, the length of the rectangular metal strip 12 on the top of the cross metal strip is l 2 = 1.5mm, width w 2 =0.2mm, the side length l of the square metal patch 15 in the fractal structure 14 3 =1.8mm, the first level of rectangular groove 16 wide d 1 =1mm, the width of the second-level rectangular groove 17 is d 2 =0.6mm, rectangular slit 22 length g=1.7mm, width g w =0.4mm, distance l between two adjacent rectangular slits 22 4 =2mm, the thickness h of the first dielectric substrate 4 1 =0.05mm, relative permittivity εr1 =3.5, the thickness h of the second dielectric substrate 5 2 =0.3mm, relative permittivity ε r2 =3.5, the thickness h of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com