Motor variable frequency starting cabinet

A technology of variable frequency start and frequency converter, which is applied in the direction of motor starter, motor generator/starter, AC motor control, etc. It can solve the problems of reducing one-time investment cost and increasing the cost of motor start control, etc., and achieve equipment manufacturing cost Increase, avoid impact, and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

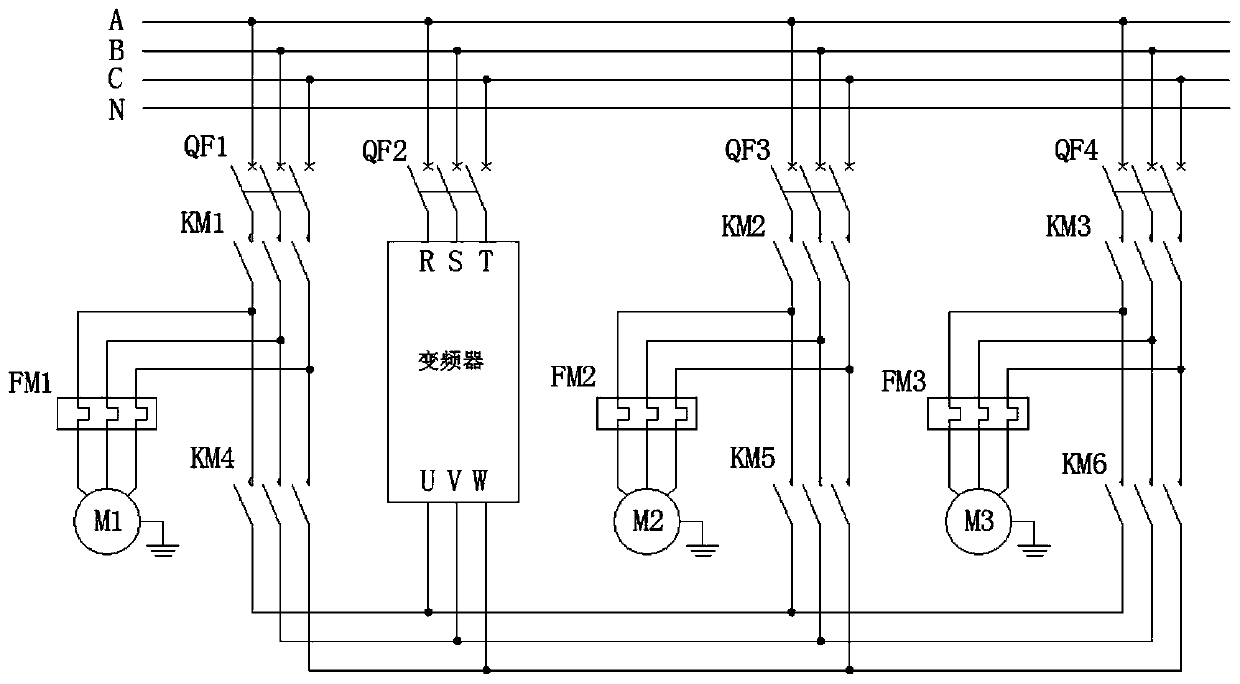

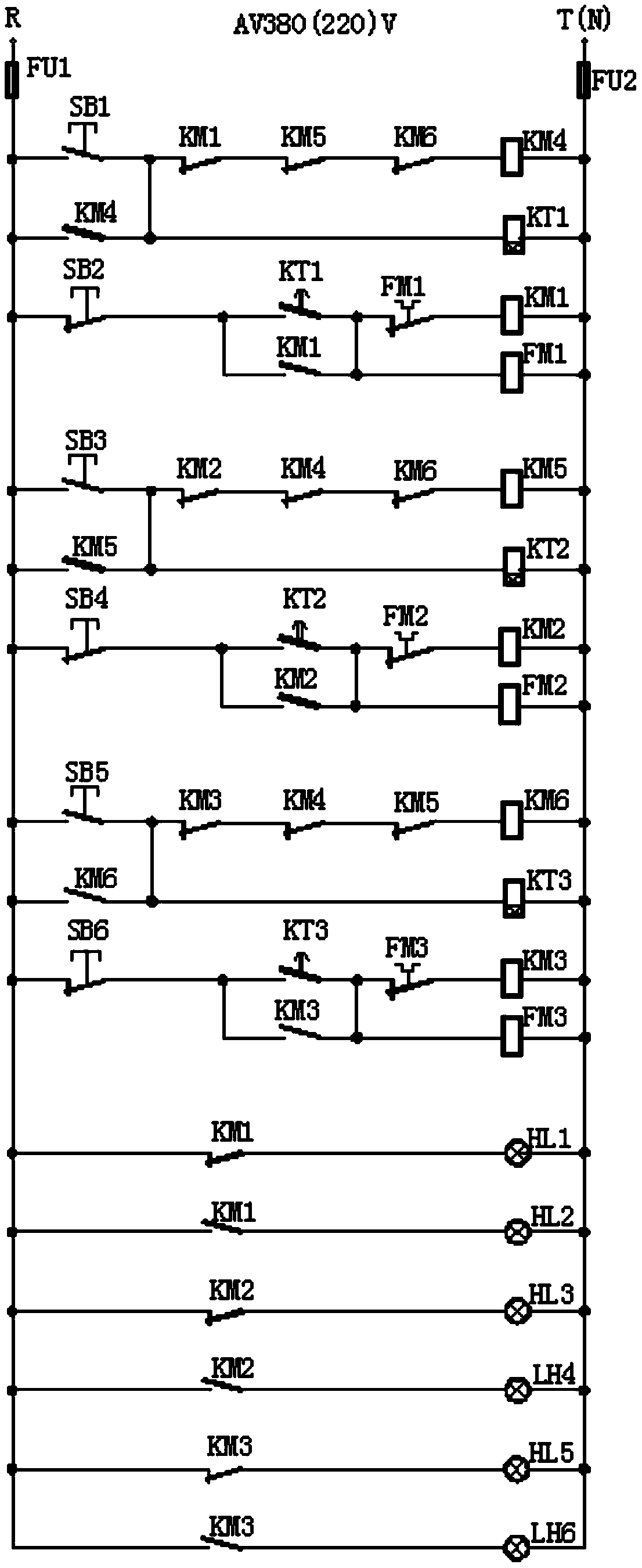

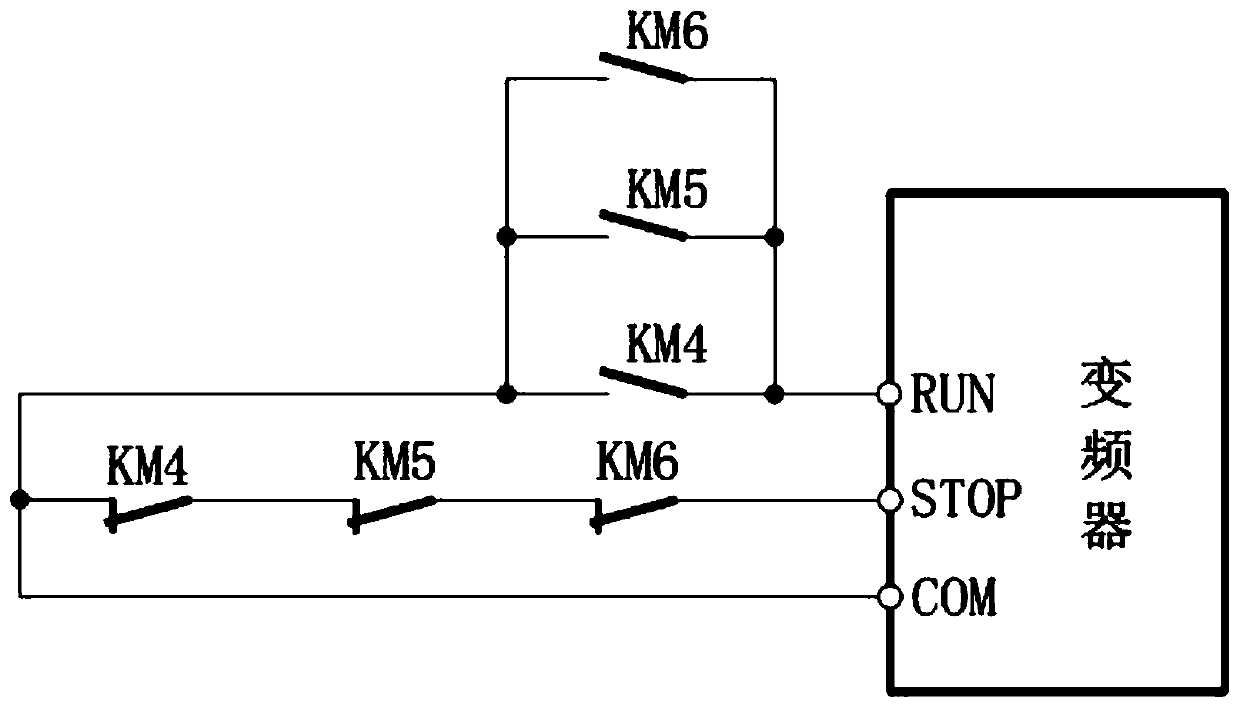

[0030] Example: such as figure 1 , 2 , 3, take the starting process of one inverter starting three motors as an example:

[0031] 1 Start motor M1

[0032] (1) The signal light HL1 is on, M1 can be started, and the circuit breakers QF1 and QF2 can be closed;

[0033] ⑵Press the start button SB1, figure 2 The electric pull-in of the KM4 coil in the middle, figure 1 The main contact of KM4 is closed, image 3 The normally open auxiliary contact of KM4 is closed, the inverter enters the starting state, and the motor M1 is powered on to start. figure 2 The KM4 normally open auxiliary contact is closed and self-protected, and the time relay KT1 coil is energized to start timing;

[0034] ⑶ After the start-up process of the inverter is over, the motor M1 enters the normal running state, the time relay KT1 settling time is up, its normally open auxiliary contact is closed, and the coil of the contactor KM1 is energized and closed. figure 2 The normally closed auxiliary cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com