Degradable high strength composite bubble film and processing method thereof

A bubble film, high-strength technology, used in sustainable manufacturing/processing, chemical instruments and methods, climate sustainability, etc. High temperature resistance, not easy to be damaged, and the effect of improving the degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

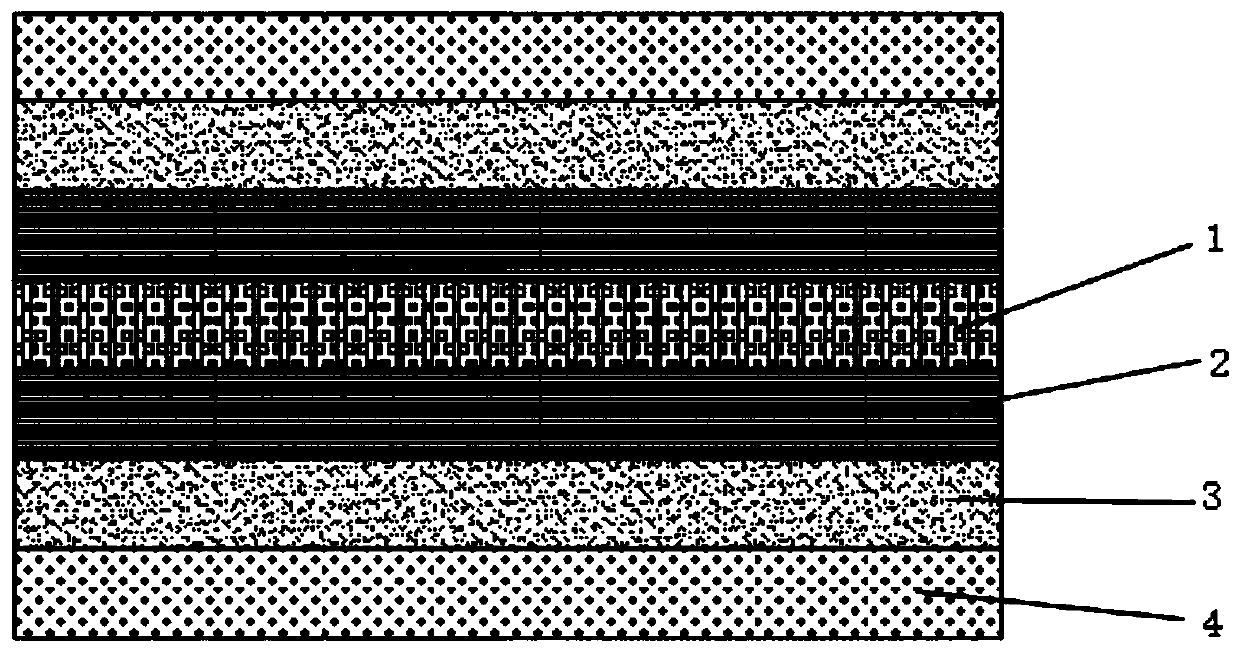

[0025] A degradable high-strength composite bubble film, comprising a bubble film layer 1, a reinforced layer 2, a wear-resistant layer 3 and a flame retardant layer 4. The bottom side of the bubble film layer 1 is provided with a reinforced layer 2, and the wear-resistant layer 3 is provided on the reinforced On the bottom side of layer 2, the flame-retardant layer 4 is arranged on the bottom side of the wear-resistant layer 3, and the top side of the bubble film layer 1 is symmetrically arranged with a reinforced layer 2, a wear-resistant layer 3 and a flame-retardant layer 4 in sequence.

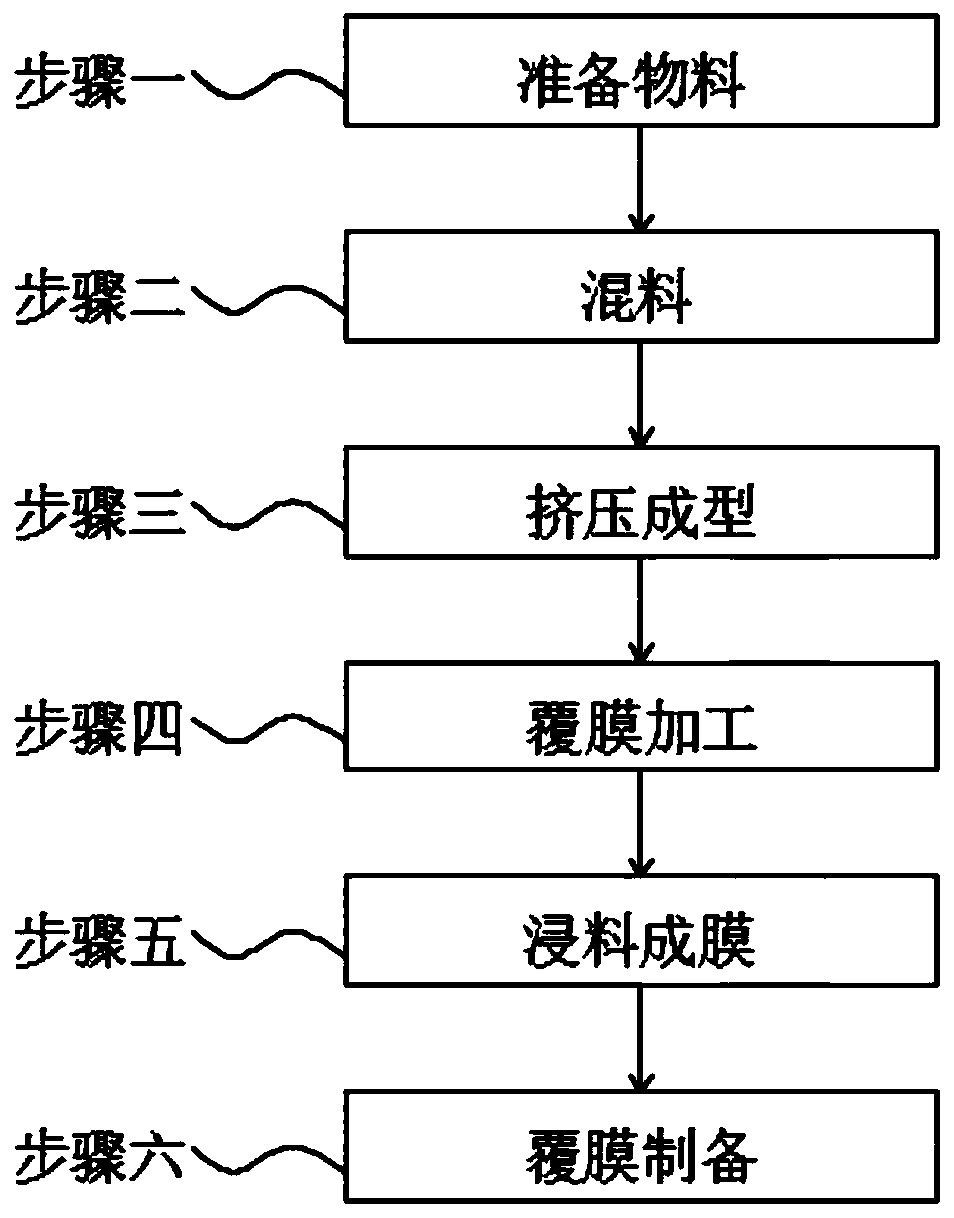

[0026] A method for processing a degradable high-strength composite bubble film includes the following steps: step one, preparing materials; step two, mixing; step three, extrusion molding; step four, laminating processing; step five, The immersion material is formed into a film; Step 6, the preparation of the film;

[0027] Among them, in the above step one, weigh polyethylene, antibacterial ...

Embodiment 2

[0034] A degradable high-strength composite bubble film, comprising a bubble film layer 1, a reinforced layer 2, a wear-resistant layer 3 and a flame retardant layer 4. The bottom side of the bubble film layer 1 is provided with a reinforced layer 2, and the wear-resistant layer 3 is provided on the reinforced On the bottom side of layer 2, the flame-retardant layer 4 is arranged on the bottom side of the wear-resistant layer 3, and the top side of the bubble film layer 1 is symmetrically arranged with a reinforced layer 2, a wear-resistant layer 3 and a flame-retardant layer 4 in sequence.

[0035] A method for processing a degradable high-strength composite bubble film includes the following steps: step one, preparing materials; step two, mixing; step three, extrusion molding; step four, laminating processing; step five, The immersion material is formed into a film; Step 6, the preparation of the film;

[0036] Among them, in the above step one, weigh polyethylene, antibacterial ...

Embodiment 3

[0043] A degradable high-strength composite bubble film, comprising a bubble film layer 1, a reinforced layer 2, a wear-resistant layer 3 and a flame retardant layer 4. The bottom side of the bubble film layer 1 is provided with a reinforced layer 2, and the wear-resistant layer 3 is provided on the reinforced On the bottom side of layer 2, the flame-retardant layer 4 is arranged on the bottom side of the wear-resistant layer 3, and the top side of the bubble film layer 1 is symmetrically arranged with a reinforced layer 2, a wear-resistant layer 3 and a flame-retardant layer 4 in sequence.

[0044] A method for processing a degradable high-strength composite bubble film includes the following steps: step one, preparing materials; step two, mixing; step three, extrusion molding; step four, laminating processing; step five, The immersion material is formed into a film; Step 6, the preparation of the film;

[0045] Among them, in the above step one, weigh polyethylene, antibacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com