Track-type biodegradation tank and working method thereof

A biodegradation pool and track-type technology, applied in biochemical equipment and methods, biomass post-treatment, biomass pre-treatment, etc., can solve problems such as low energy efficiency, unreasonable installation, and high noise, and achieve good results. The effect of stable water flow and compact and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing, the present invention will be further described.

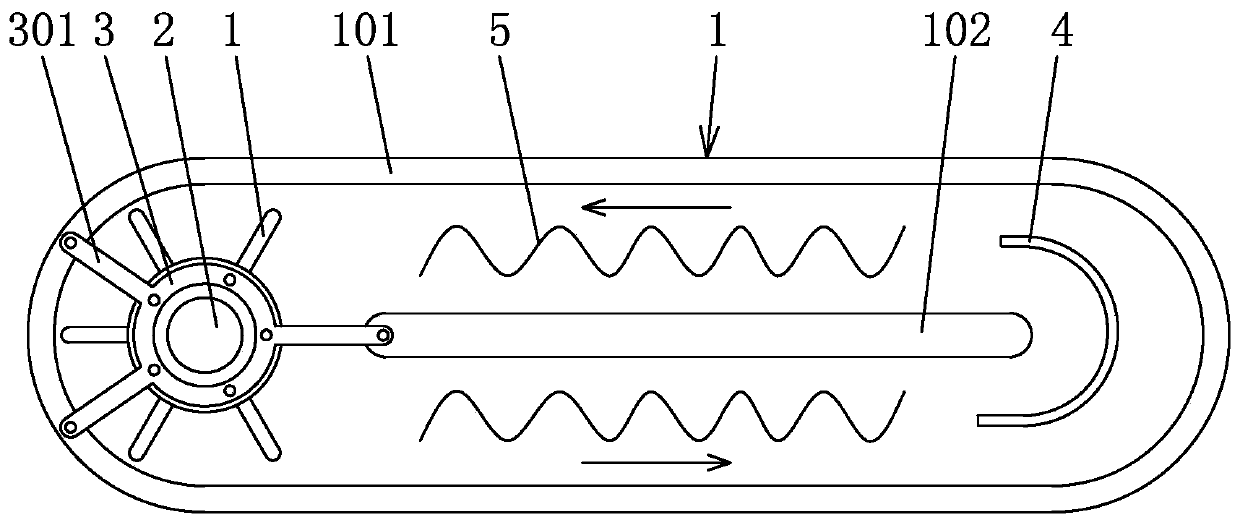

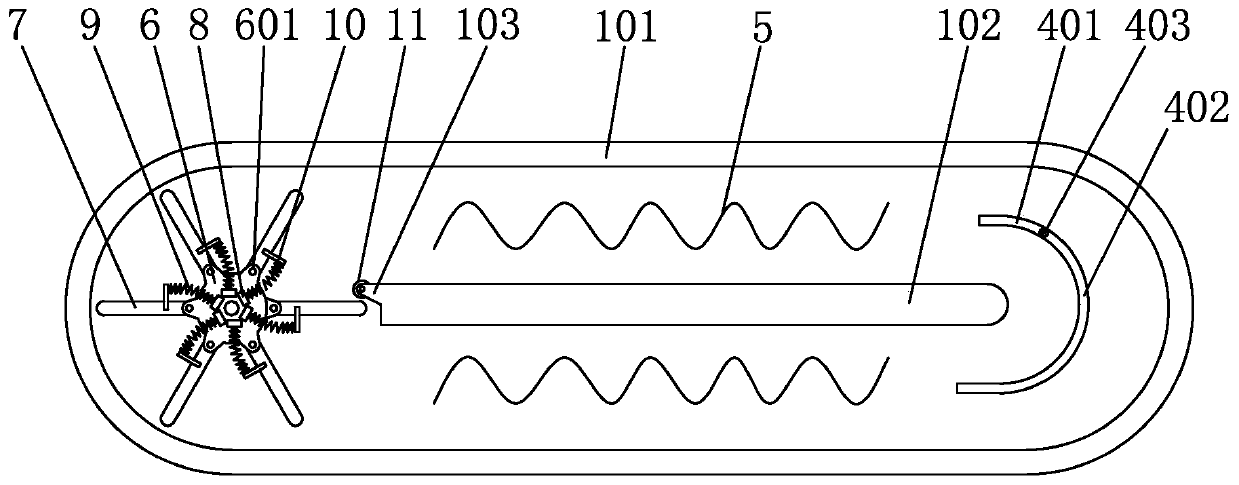

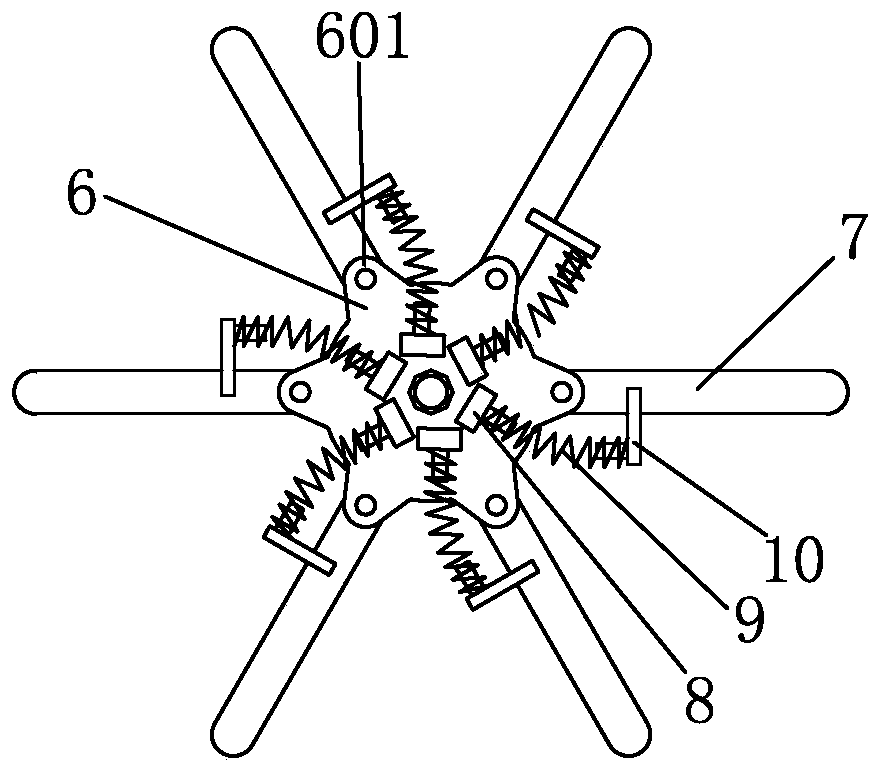

[0022] like figure 1 As shown, the runway-type biodegradation pool includes a circular runway-type pool body 1, and a paddle machine 2 that promotes the water body in the runway pool to flow along the runway direction. The pool body includes a runway outer ring 101 and an inner isolation pier 102. For degrading organisms5, such as: microalgal organisms. The wheel machine is fixed in the arc-shaped bend on one side of the pool body. The wheel machine includes a motor and an impeller. The motor is fixed on the bracket 3, and the support arm 301 is arranged in the circumferential direction of the bracket, and is fixed to the pool by the support arm and the locking piece. One end of the inner isolation pier and the outer ring of the runway. The impeller of the turbomachine is immersed in the water body as a whole, and the rotation axis of the impeller is perpendicular to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com