Automatic production system and process for PVC modified stabilizer

A production system and stabilizer technology, applied in lighting and heating equipment, drying, drying machines, etc., can solve the problems of inability to realize integrated continuous production, waste of materials, low quality, etc., and improve production efficiency and production efficiency. The effect of improving yield, improving product quality and avoiding reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

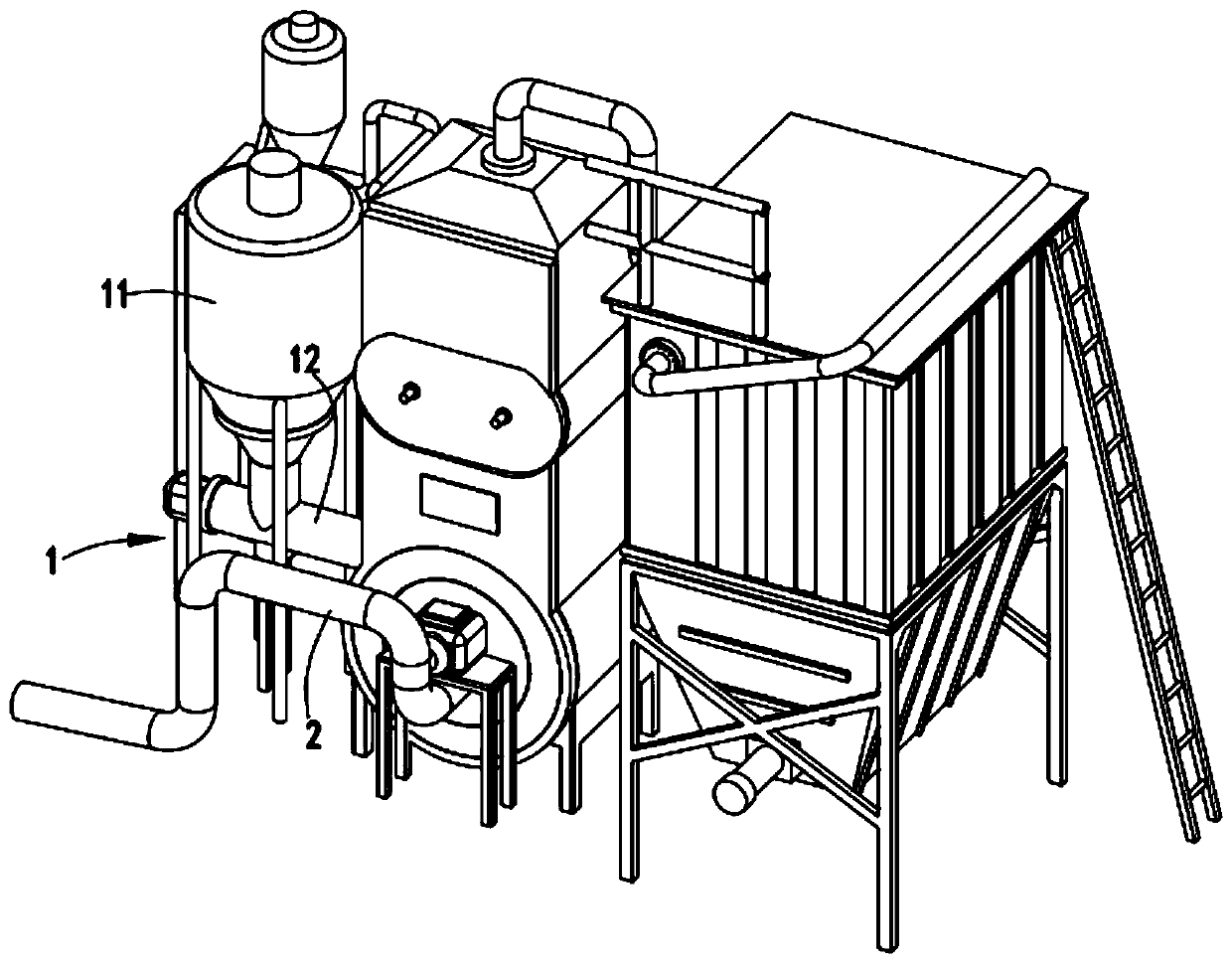

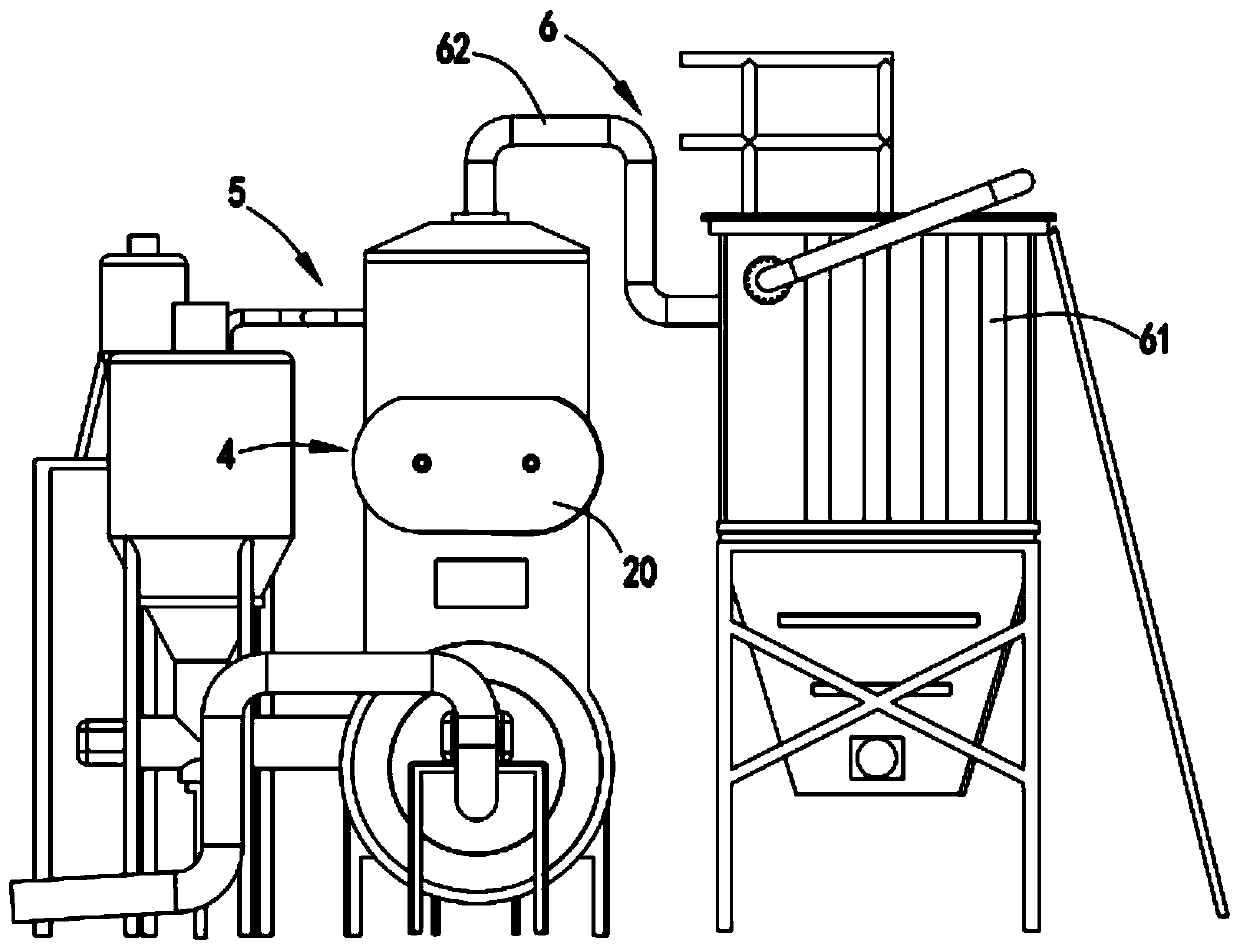

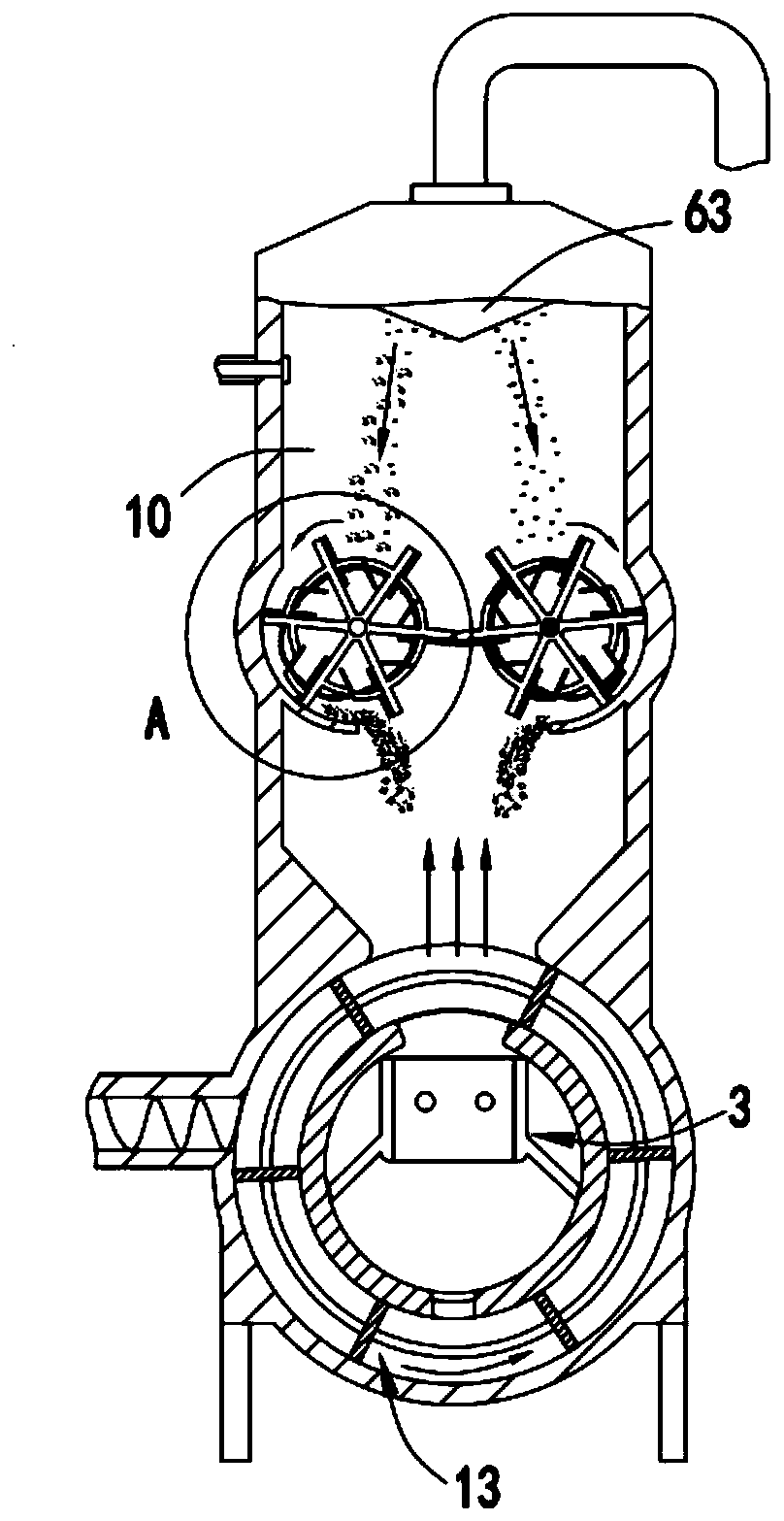

[0058] Such as Figure 1 to Figure 11 As shown, a PVC modified stabilizer automatic production system includes a feeding mechanism 1, a hot air pipe 2, a depolymerization mechanism 3, a secondary crushing mechanism 4, a coating machine injection mechanism 5, and a discharge mechanism 6. The secondary crushing mechanism 4 includes a crushing assembly a41 and a crushing assembly b42 arranged symmetrically left and right;

[0059] The feeding mechanism 1 is used to input the material to be depolymerized and transfer the material to...

Embodiment 2

[0078] Such as Figure 4 and Figure 9 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that: further, an extension baffle 4127 is provided on the side of the crushing plate 4124 close to the bearing plate 4122, and an arc-shaped guide plate 4128 is extended from the lower side of the arc-shaped portion 413 toward the center of the cavity.

[0079] In this embodiment, the setting of the extension baffle 4127 can prevent materials from entering the space behind the crushing plate 4124 during the sliding process of the crushing plate 4124, resulting in waste of materials;

[0080] In addition, the arrangement of the arc-shaped guide plate 4128 can guide the crushed powder to the middle position, so that it can ...

Embodiment 3

[0082] Such as Figure 12 Shown, a kind of PVC modified stabilizer automatic production process comprises following production steps:

[0083] Step 1, feeding process, the material to be depolymerized is conveyed backward;

[0084] Step 2, quantitative process, the materials conveyed in step 1 are quantitatively conveyed to the depolymerization station under the drive of the fixed material rotary conveying assembly 13, and the materials are dried during the conveying process;

[0085] Step 3, dispersing process, the dispersing wheel group 32 located at the depolymerization station disperses the quantitatively input materials, and the undispersed materials fall to the fixed material rotary conveying assembly 13 and the next batch to be decomposed Convergence of aggregated materials;

[0086] Step 4, the blowing process, the hot air pipe 2 blows high-speed hot air from the bottom of the depolymerization station, and the high-speed hot air drives the dispersed powder and some p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com