Special POZD repairing material for drinking water facilities, and preparation method and repairing construction method thereof

A technology of repairing materials and drinking water, which is applied in the field of repairing materials, can solve problems such as poor adhesion, easy delamination, and inapplicability, and achieve the effects of improving adhesion, preventing damage, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a preparation method of the above-mentioned special POZD repair material for drinking water facilities, comprising the following steps:

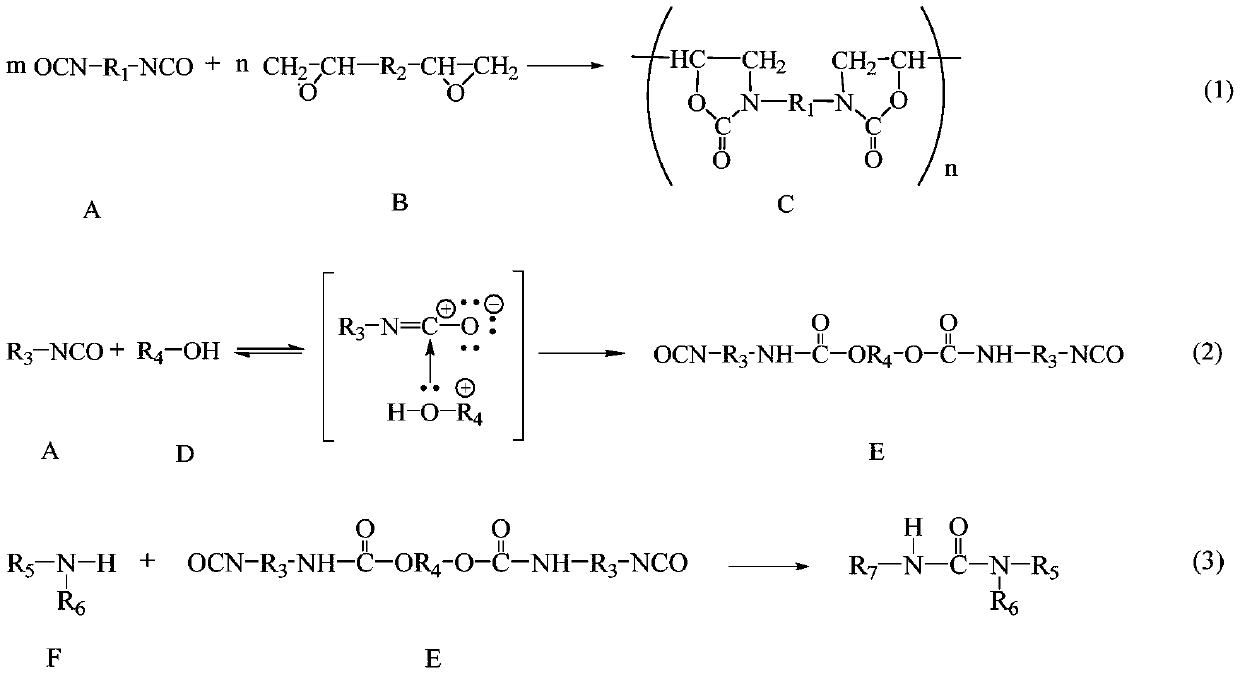

[0038] S1 Preparation of component A: aliphatic isocyanate and epoxy resin were stirred and reacted at 200°C for 0.5h to obtain reactant A; polyether polyol and hindered amine chain extender were placed in a reaction vessel, and the reaction vessel was heated to 100°C and keep vacuuming for 2h, lower the temperature to 40°C and return to normal pressure, then add the reactant A into the reaction vessel, raise the temperature to 80°C, stir and react for 2h to obtain formazan with an NCO value of 6% to 12%. components;

[0039] S2 Preparation of component B: sterically hindered amine chain extender, difunctional amino-terminated polyether and trifunctional amino-terminated polyether are stirred and mixed evenly to obtain component B.

[0040] In a preferred embodiment, in the step o...

Embodiment 1

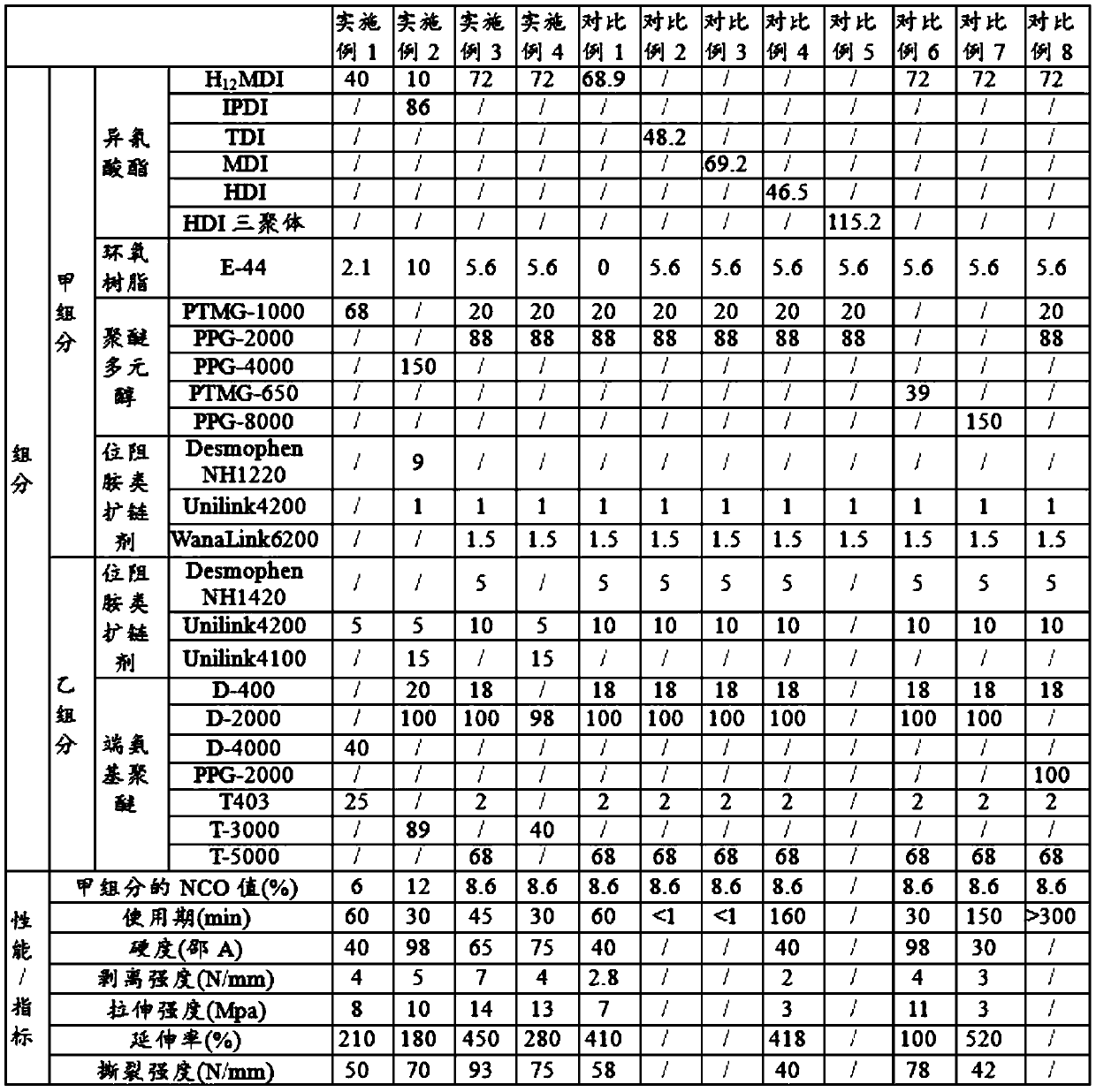

[0048] The special POZD repair material for drinking water facilities is solvent-free and catalyst-free. It includes component A and component B at a weight ratio of 0.8:1. The specific composition of component A and component B is shown in Table 1.

[0049] The preparation method of the special POZD repair material for above-mentioned drinking water facilities comprises the following steps:

[0050] (1) Preparation of component A: Stir and react aliphatic isocyanate and epoxy resin at 200°C for 0.5h to obtain reactant A; place polyether polyol in a reaction vessel, heat the reaction vessel to 100°C and evacuate to -0.1Mpa, keep it for 2h, lower the temperature to 40°C and return to normal pressure, add the reactant A into the reaction vessel, raise the temperature to 80°C, stir and react for 2h to obtain component A, its NCO value is shown in Table 1 ;

[0051] (2) Preparation of component B: sterically hindered amine chain extender, difunctional amino-terminated polyether a...

Embodiment 2

[0057] The difference between the special POZD repair material for drinking water facilities provided in this embodiment and embodiment 1 is only: the weight ratio of component A and component B is 1.5:1; the specific composition of component A and component B is different from the embodiment 1, and Component A includes a hindered amine chain extender, see Table 1 for details.

[0058] The difference between the preparation method of the POZD repair material for drinking water facilities provided in this example and Example 1 is that when preparing component A, the polyether polyol and the hindered amine chain extender are placed in the reaction vessel together.

[0059] The difference between the repair construction method of the POZD repair material for drinking water facilities provided in this example and Example 1 is that when the repair materials are mixed, component A and component B are mixed at a weight ratio of 1.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com