Preparation of sic fiber by mixing ultra-high temperature ceramic composite material and its method and application

A technology of ultra-high temperature ceramics and composite materials, applied in the direction of inorganic raw material rayon, etc., can solve the problems of poor bending and shearing resistance, prone to cracks, carbon-rich, etc. High temperature performance, the effect of improving the degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

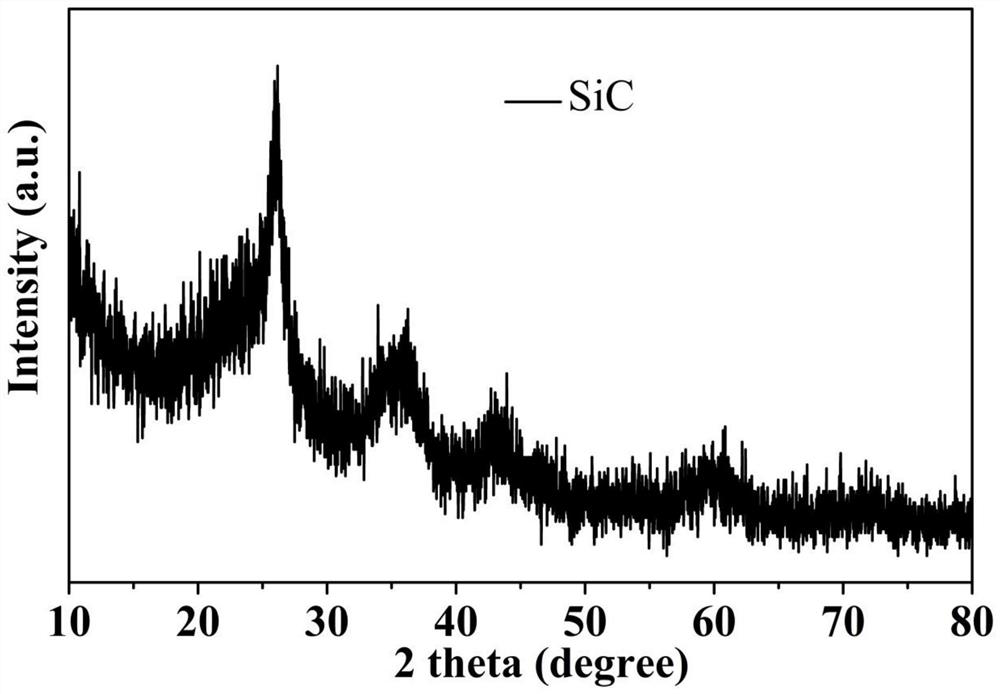

Image

Examples

Embodiment 1

[0019] Embodiment 1 proposes a method for preparing SiC fibers by adding ultra-high temperature ceramic composite materials, including the following steps:

[0020] (1) First add glycerol and trimethylmonochlorosilane dropwise in dimethyldichlorosilane with stirring, then add reaction metal and xylene, then heat to 100°C to melt the reaction metal into a liquid state and stir When the solution turns purple, reduce the temperature to room temperature until the purple is no longer deep, then cool and filter, wash with alcohol for 3 times, dry and grind into powder; among them, dimethyldichlorosilane, glycerol and trimethyl The volume ratio of monochlorosilane is 10:2:1; the reaction metal is potassium or magnesium, the reaction metal accounts for 13% of the mass of the reactant, and xylene accounts for 5% of the total volume of the reactant.

[0021] (2) Polydimethylsilane, polymer organo-zirconane, polymer organoboroaluminum-zircone and polycarbosilane are mixed according to th...

Embodiment 2

[0024] Embodiment 2 proposes a method for preparing SiC fibers by adding ultra-high temperature ceramic composite materials, including the following steps:

[0025] (1) First add glycerol and trimethylmonochlorosilane dropwise in dimethyldichlorosilane with stirring, then add reaction metal and xylene, then heat to 150°C to melt the reaction metal into a liquid state and stir When the solution turns purple, reduce the temperature to room temperature until the purple is no longer deep, then cool and filter, wash with alcohol for 3 times, dry and grind into powder; among them, dimethyldichlorosilane, glycerol and trimethyl The volume ratio of monochlorosilane is 10:2:1; the reaction metal is potassium or magnesium, the reaction metal accounts for 7% of the mass of the reactant, and xylene accounts for 8% of the total volume of the reactant.

[0026] (2) Polydimethylsilane, polymer organo-zirconane, polymer organoboroaluminum-zircone and polycarbosilane are mixed according to the...

Embodiment 3

[0029] Embodiment 3 proposes a method for preparing SiC fibers by adding ultra-high temperature ceramic composite materials, including the following steps:

[0030] (1) First add glycerol and trimethylmonochlorosilane dropwise in dimethyldichlorosilane with stirring, then add reaction metal and xylene, then heat to 125°C to melt the reaction metal into a liquid state and stir When the solution turns purple, reduce the temperature to room temperature until the purple is no longer deep, then cool and filter, wash with alcohol for 3 times, dry and grind into powder; among them, dimethyldichlorosilane, glycerol and trimethyl The volume ratio of monochlorosilane is 10:2:1; the reaction metal is potassium or magnesium, the reaction metal accounts for 10% of the mass of the reactant, and xylene accounts for 6% of the total volume of the reactant.

[0031] (2) Polydimethylsilane, polymer organo-zirconane, polymer organoboroaluminum-zircone and polycarbosilane are mixed according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com