Intelligent doffing control system and method for lower computer of textile robot

A control system and robot technology, applied in control/adjustment system, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve the problems of high labor intensity, waste of manpower, low efficiency, etc., and achieve reduction Effects of artificial labor, efficiency improvement, and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

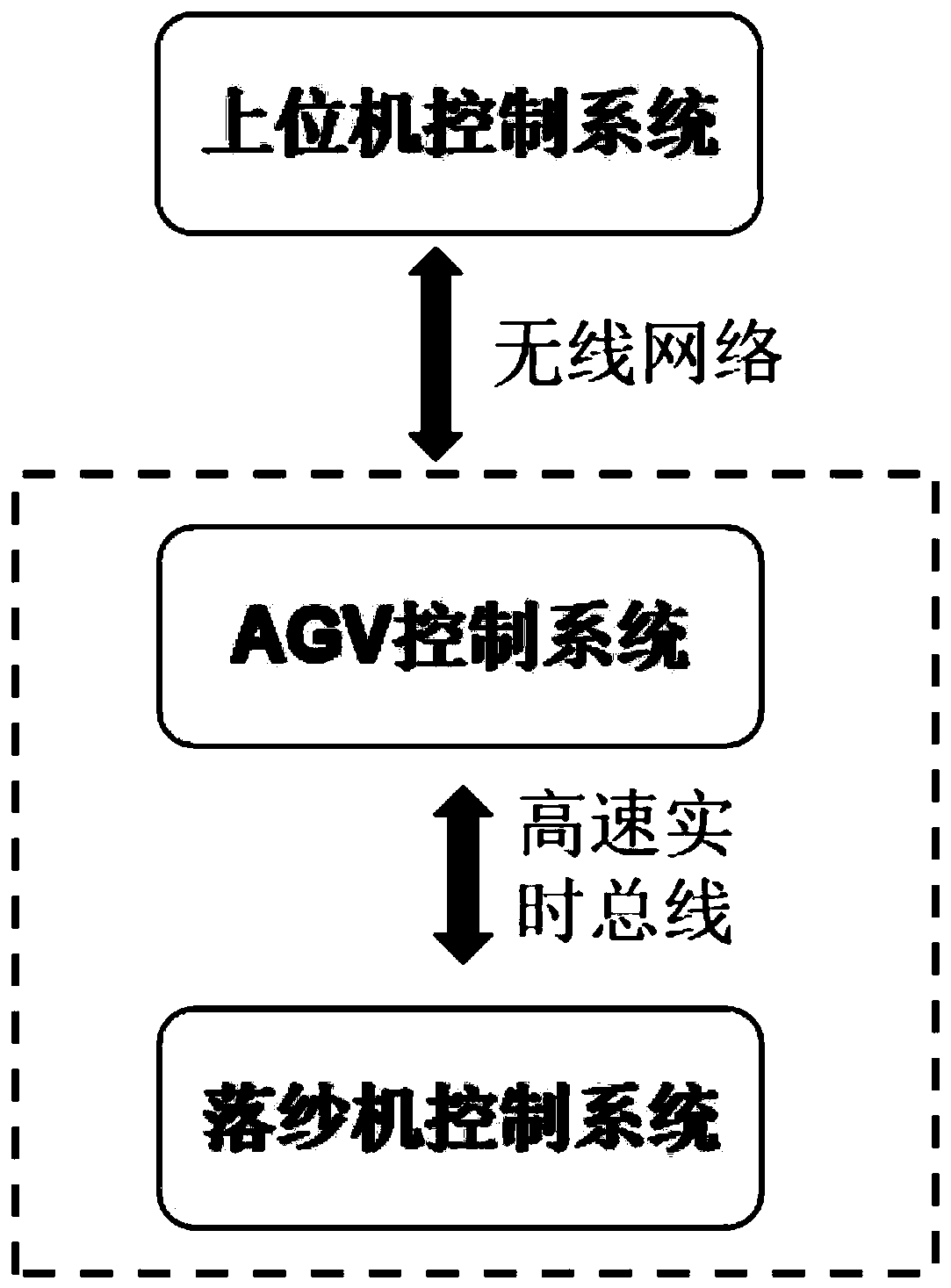

[0027] The textile robot intelligent doffing control system consists of a host computer control system and a lower computer control system. The upper computer control system is responsible for the production scheduling, production status monitoring, production data storage and other functions of multiple doffing robots. The yarn robot performs specific tasks, and the two communicate through a wireless network. The intelligent doffing robot is a mother-child composite robot integrating AGV and automatic doffing machine. Its lower computer control system is composed of AGV control system and doffing machine control system. The two control systems communicate through high-speed real-time bus.

[0028] Such as figure 1 As shown, the present invention provides an intelligent doffing control system for a lower computer of a textile robot, including an AGV control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com